Modularized cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

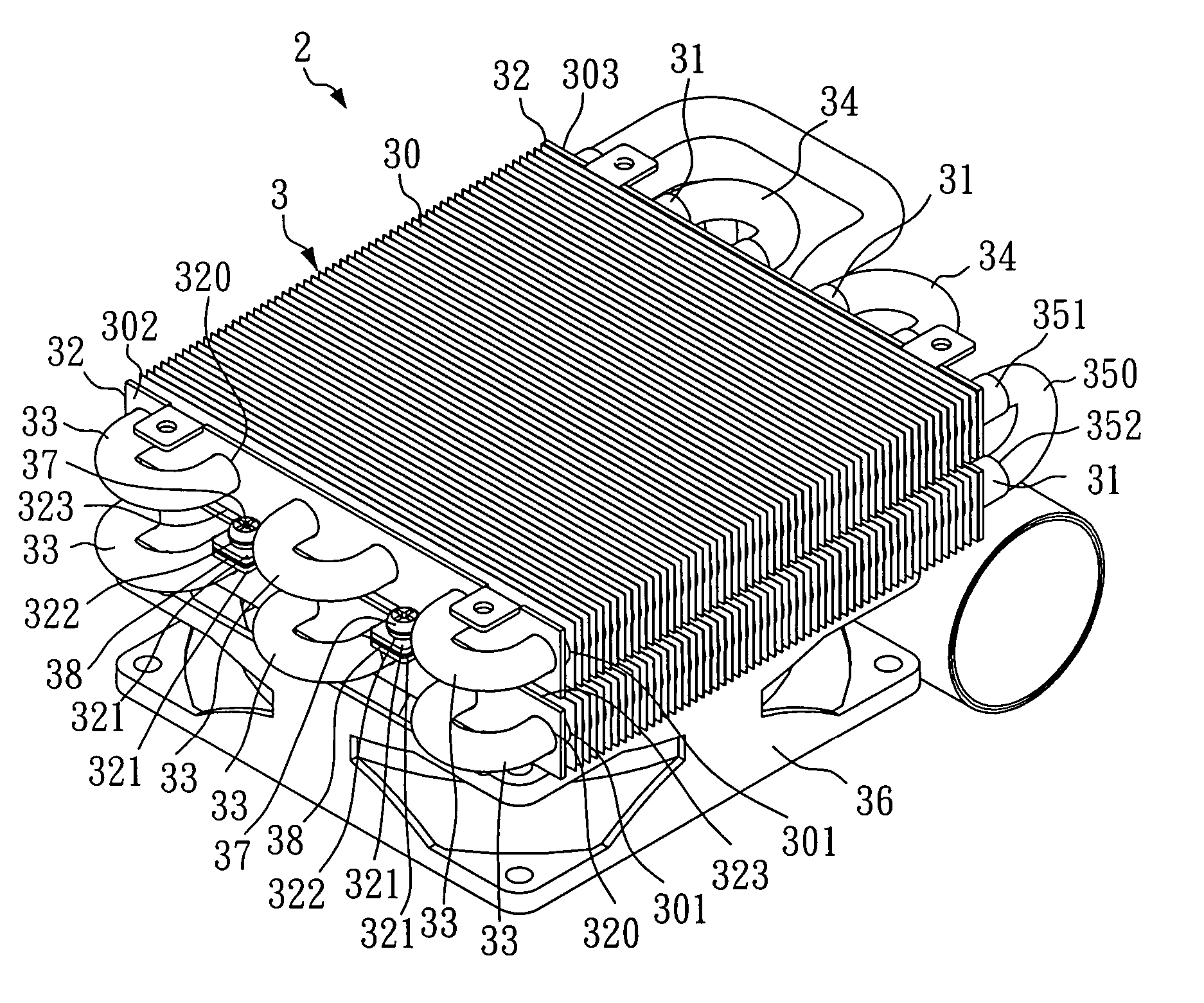

[0017] Referring to FIGS. 3-5, a modularized cooler 2 in accordance with the present invention is shown comprised of two heat radiator modules 3, a connecting tube 350, and a fan 36.

[0018] The two heat radiator modules 3 are arranged in a stack, each comprising a plurality of radiation fins 30, and a plurality of heat-exchange tubes 31, two locating plates 32, a plurality of first bends 33, and a plurality of second bends 34. According to this embodiment, the radiation fins 30 are arranged in parallel and spaced from one another in longitudinal direction at a predetermined pitch, each having a plurality of through holes 301 extending in longitudinal direction. The heat-exchange tubes 31 are straight tubes respectively longitudinally mounted inside the through holes 301 of the radiation fins 30 and arranged in parallel.

[0019] Further, the two locating plates 32 are respectively fastened to the first outer side 302 and second outer side 303 of the set of radiation fins 30 of the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com