Memory card casing having longitudinally formed ridges and radially formed ribs for support of contacts of a PCB

a memory card and casing technology, applied in the direction of electrical apparatus casings/cabinets/drawers, instruments, printed circuit structure associations, etc., can solve the problems of insufficient rigidity of memory cards, contacts are easily damaged, memory cards are easily distorted and damaged, etc., to reduce the chance of damage to pcb contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

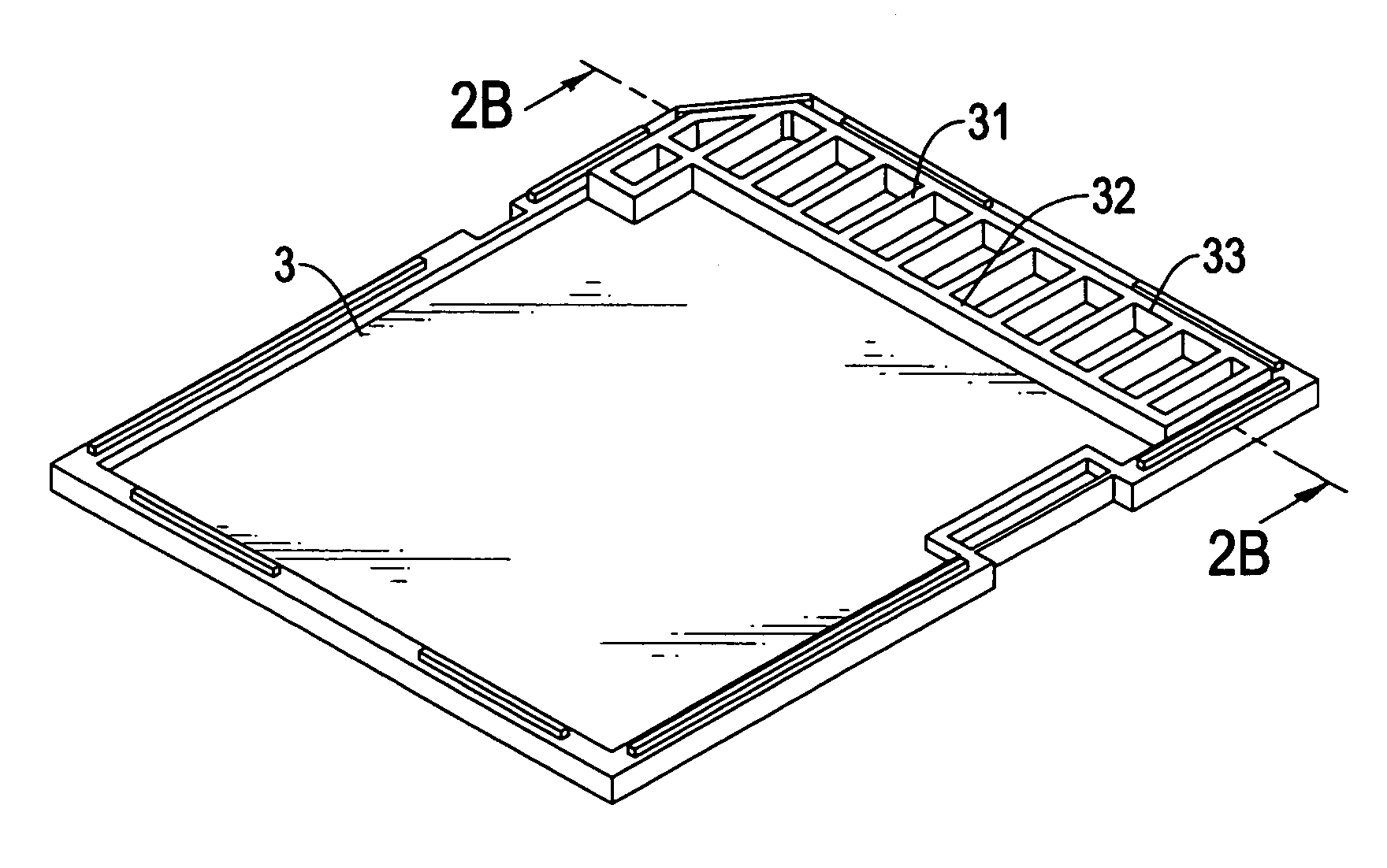

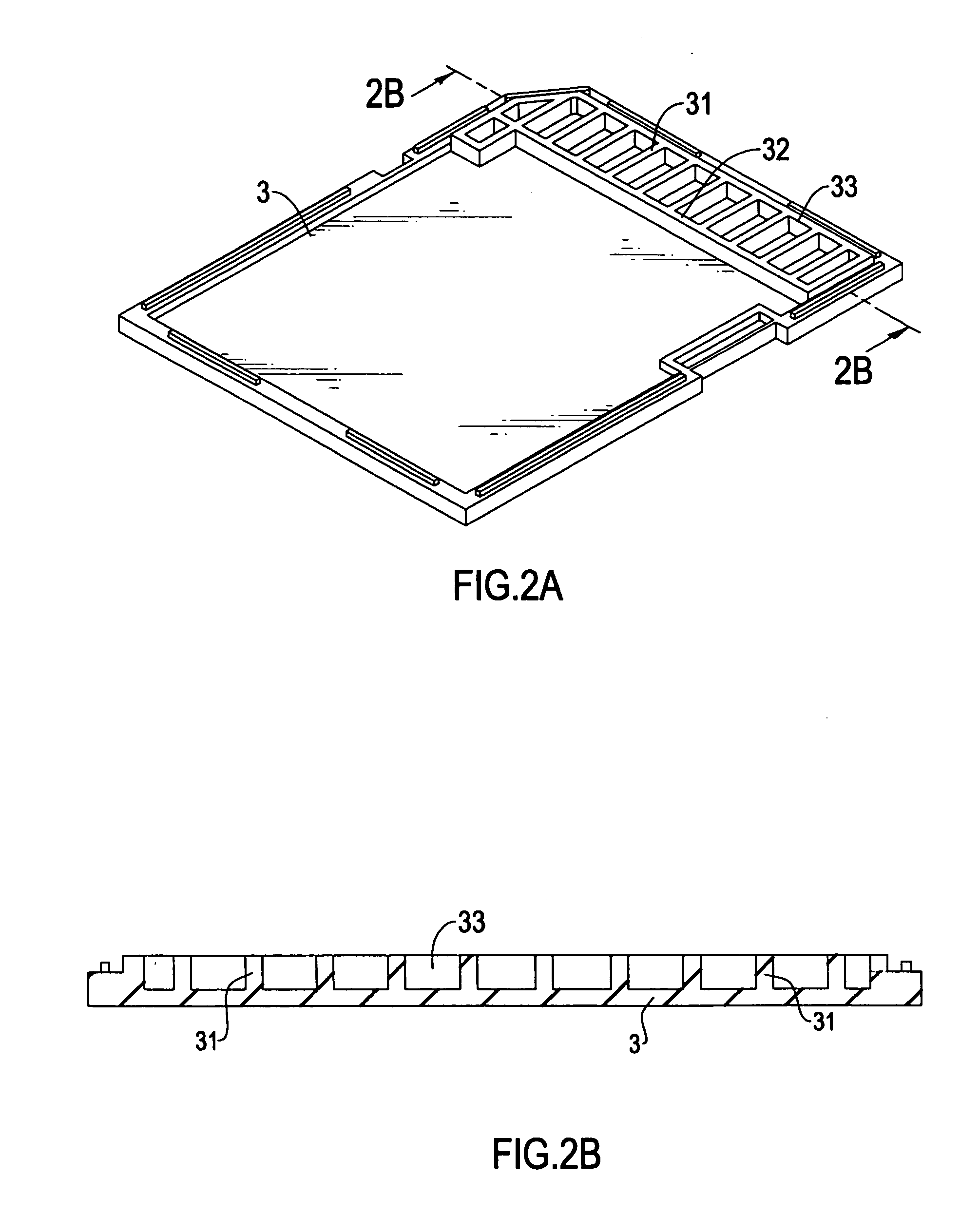

[0015] With reference to FIGS. 2A and 2B, the memory card casing is composed of a top cover (not shown) and a bottom cover (3) together with the top cover to form a receiving space for receiving therebetween a printed circuit board (PCB). The top cover has a configuration the same as that of the conventional memory card casing so that detailed description thereof is omitted.

[0016] It is noted that the bottom cover (3) has multiple longitudinal ridges (31) formed at a peripheral edge of the bottom cover (3), a first rib (32) formed on the bottom cover (3) to connect to one end of each of the longitudinal ridges (31) and a second rib (33) formed on the bottom cover (3) to connect to the other end of each of the longitudinal ridges (31) such that a rigid support is formed on the bottom cover (3) for supporting thereon contacts of the PCB. Preferably, the quantity of the longitudinal ridges is no bigger than three (3) to avoid possibility of deformation from contraction out of cold in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com