Power driven bone crusher and method for bone crushing

a technology of power driven bone crusher and bone crusher, which is applied in the direction of solid separation, medical science, prosthesis, etc., can solve the problems of large existing bone mill, cumbersome use and cleaning of expensive devices, and inability to immediately provide bone mills,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

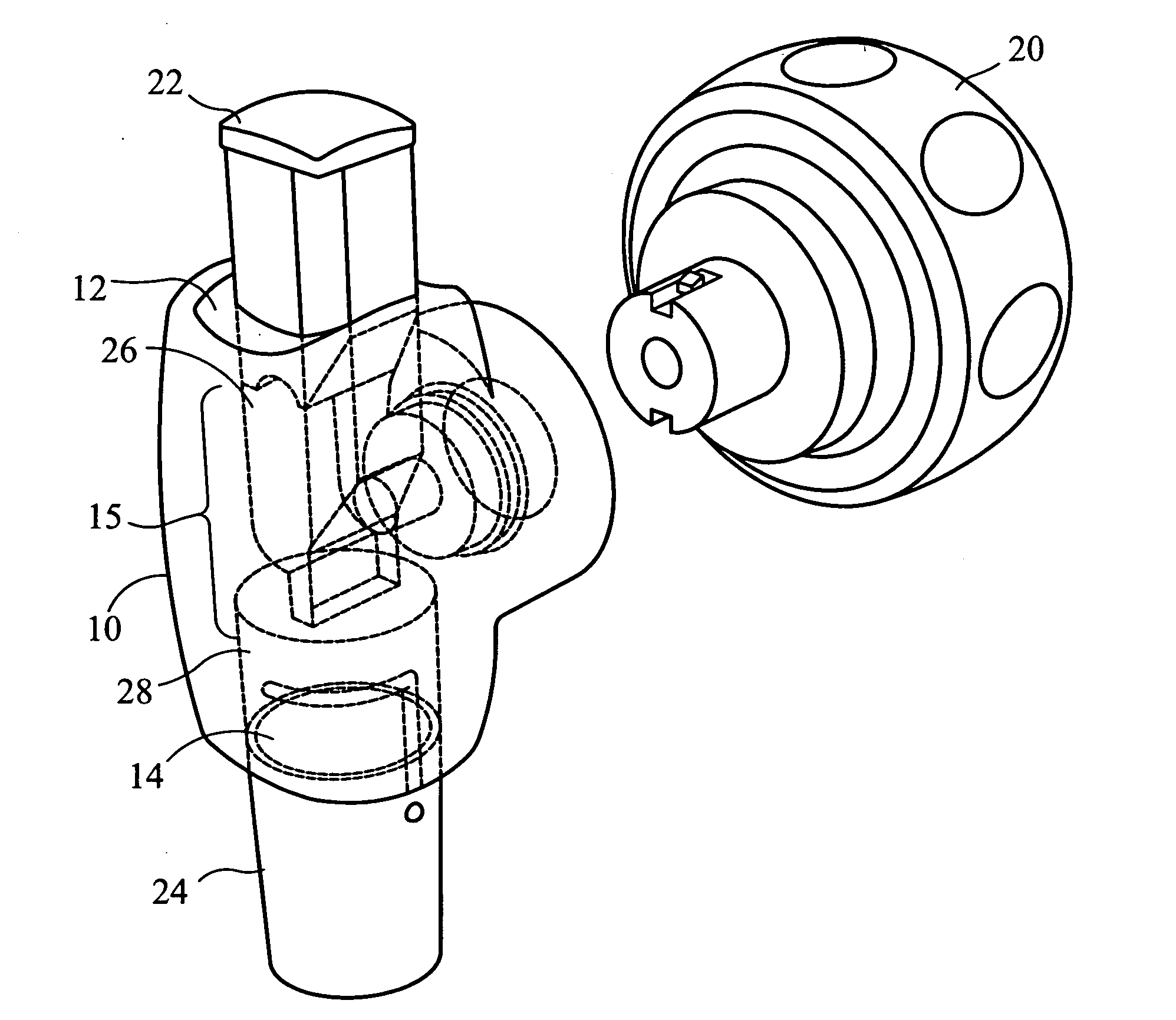

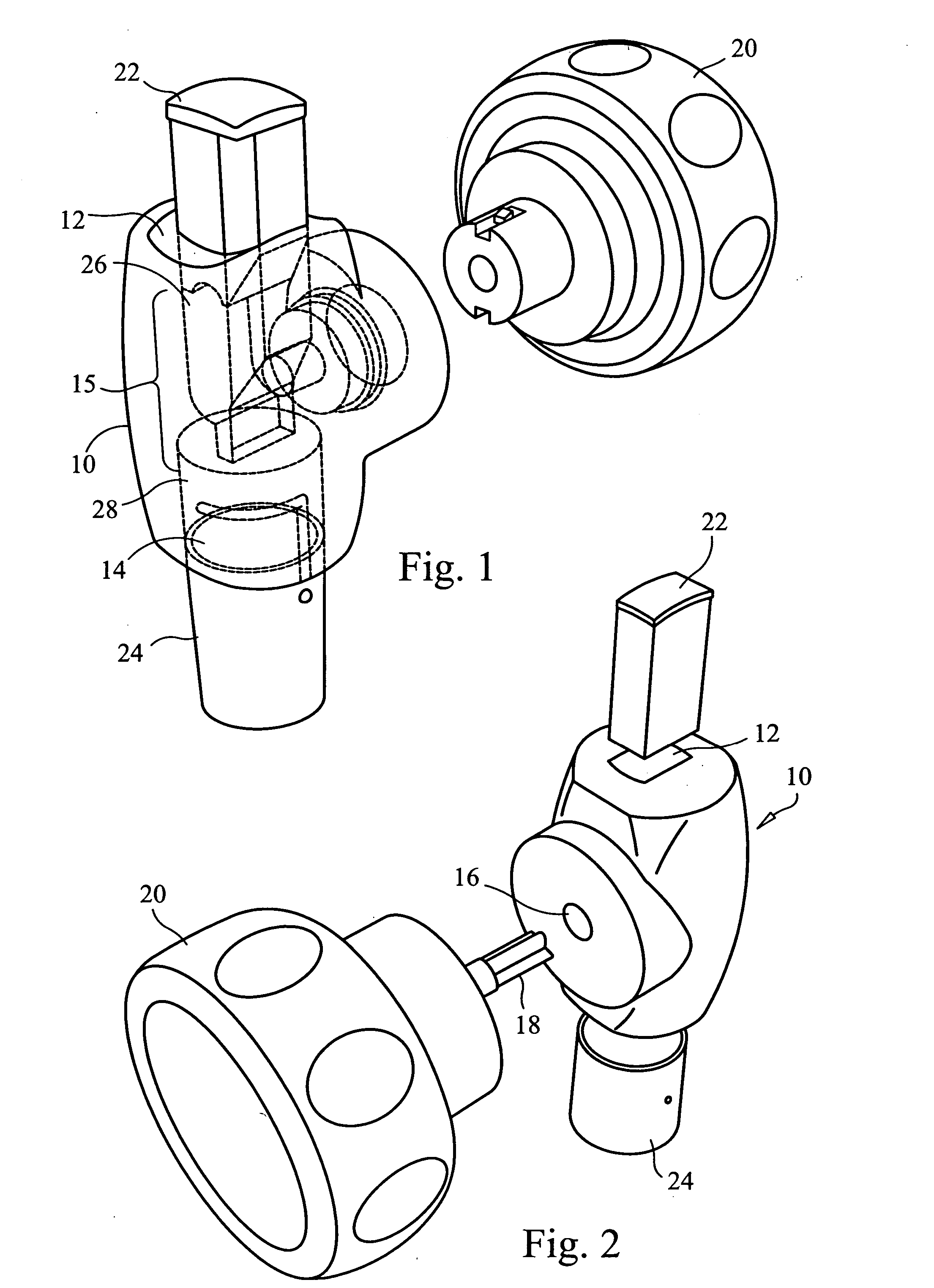

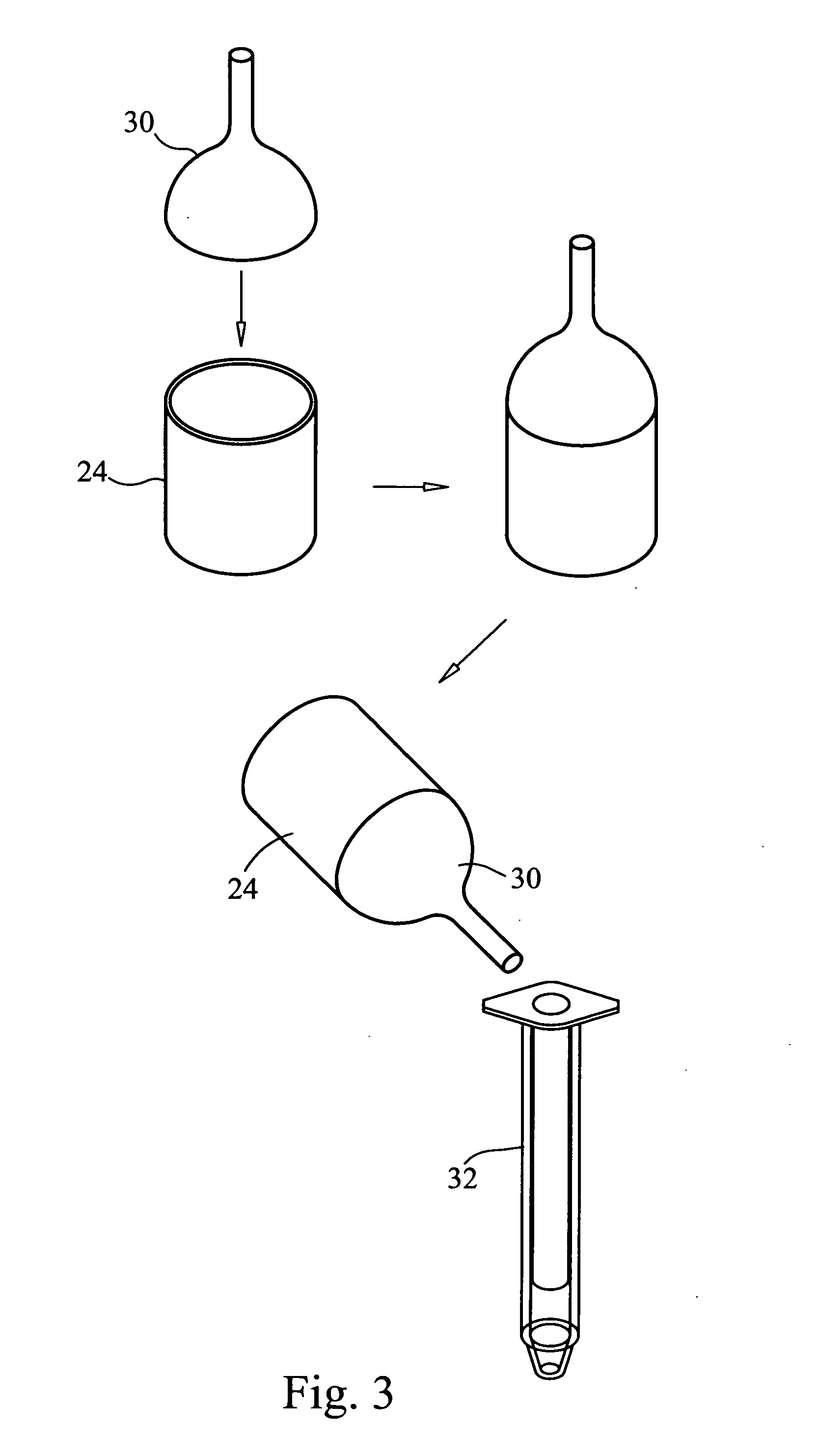

[0041] The present invention provides a disposable, hand-operated bone mill that accommodates cutting plates to produce bone chips of a selected size based on a blade installed in the mill body 10. Referring now to FIG. 1, an exemplary embodiment of the present invention includes a bone mill having a mill body 10 that defines a first opening 12, a second opening 14, and a linear passage 15 that extends from the first opening 12 to the second opening 14. The mill body 10 further includes a rotatable cutting member 18 coupled to an actuator element 20, as shown in FIG. 2. Further, the mill body 10 can include a third opening 16 through which the rotatable cutting member 18 couples to the actuator element 20. The first opening 12 can be adapted to receive a plunger 22, and a receptacle 24 can be removably coupled to the second opening 14.

[0042] The first opening 12 provides an access area into which a suitably sized bone portion can be inserted for milling. First opening 12 can be of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com