Leather treatment process

a technology of leather treatment and leather, applied in the field of leather treatment process, can solve problems such as creating worn or distressed looks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

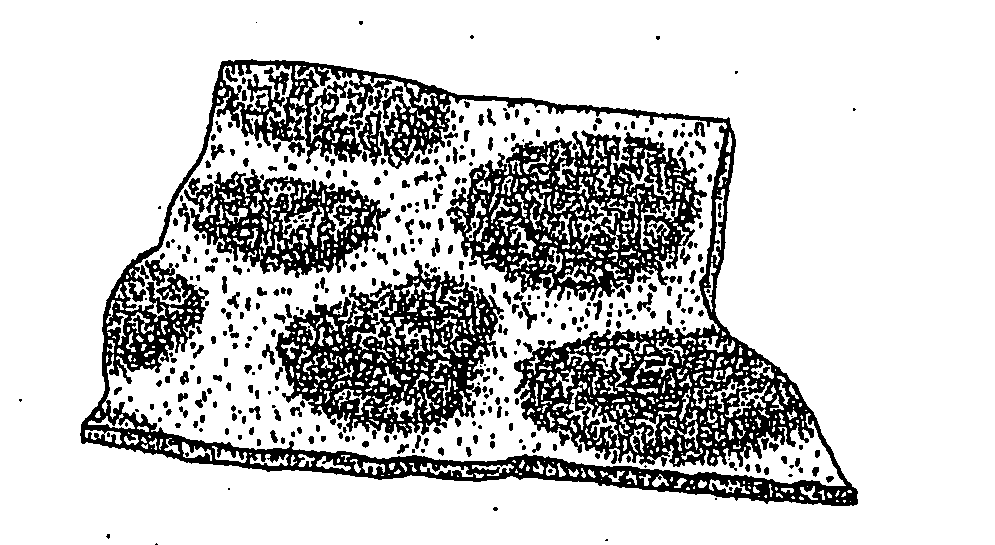

[0018] A new redesigned leather fabric is created from an existing cowhide, buffalo, goat, sheep or lambskin. The applied technology will sculpt and contour the leather to create a reversible bubble leather design ready for use in the marketplace.

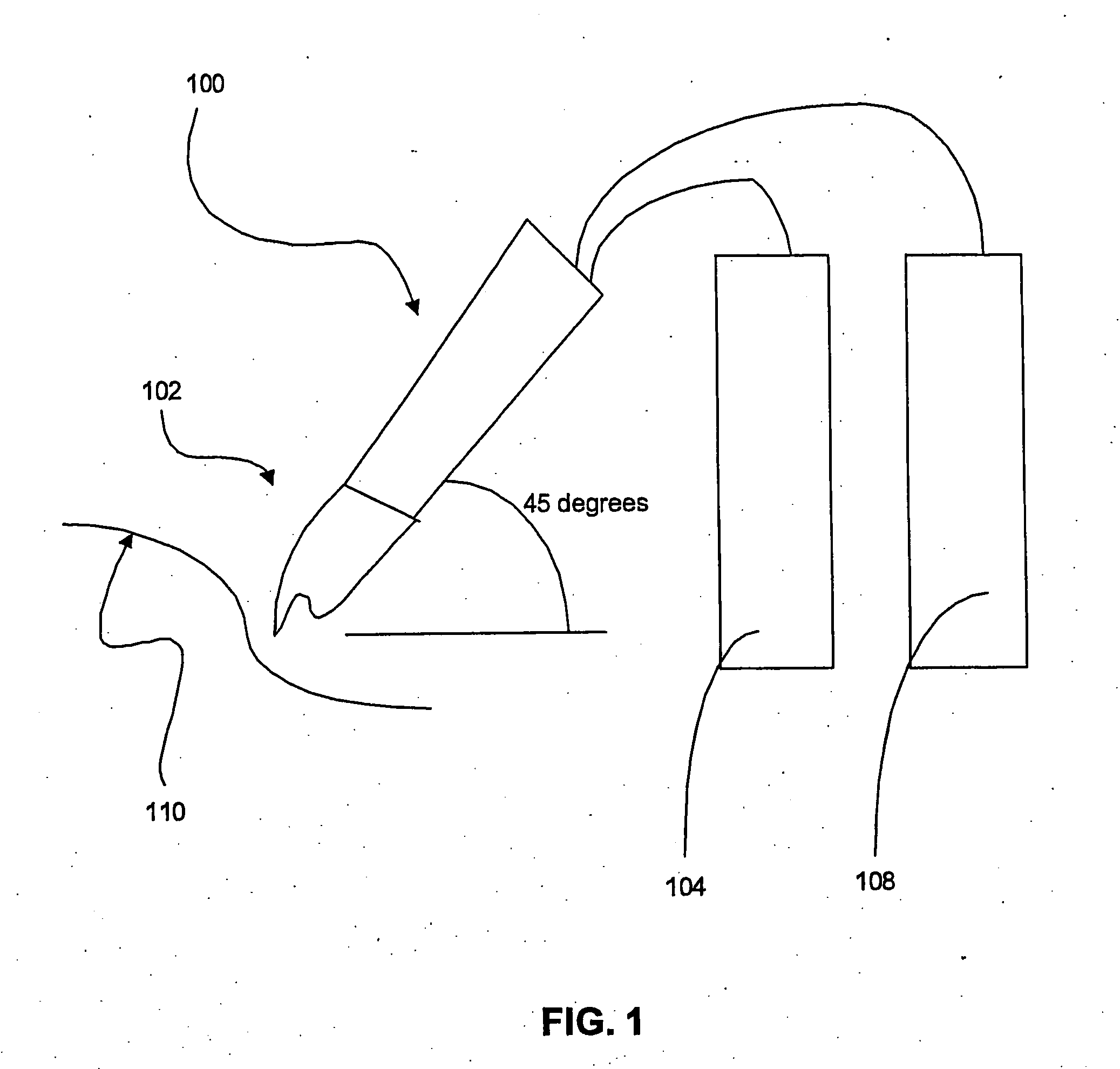

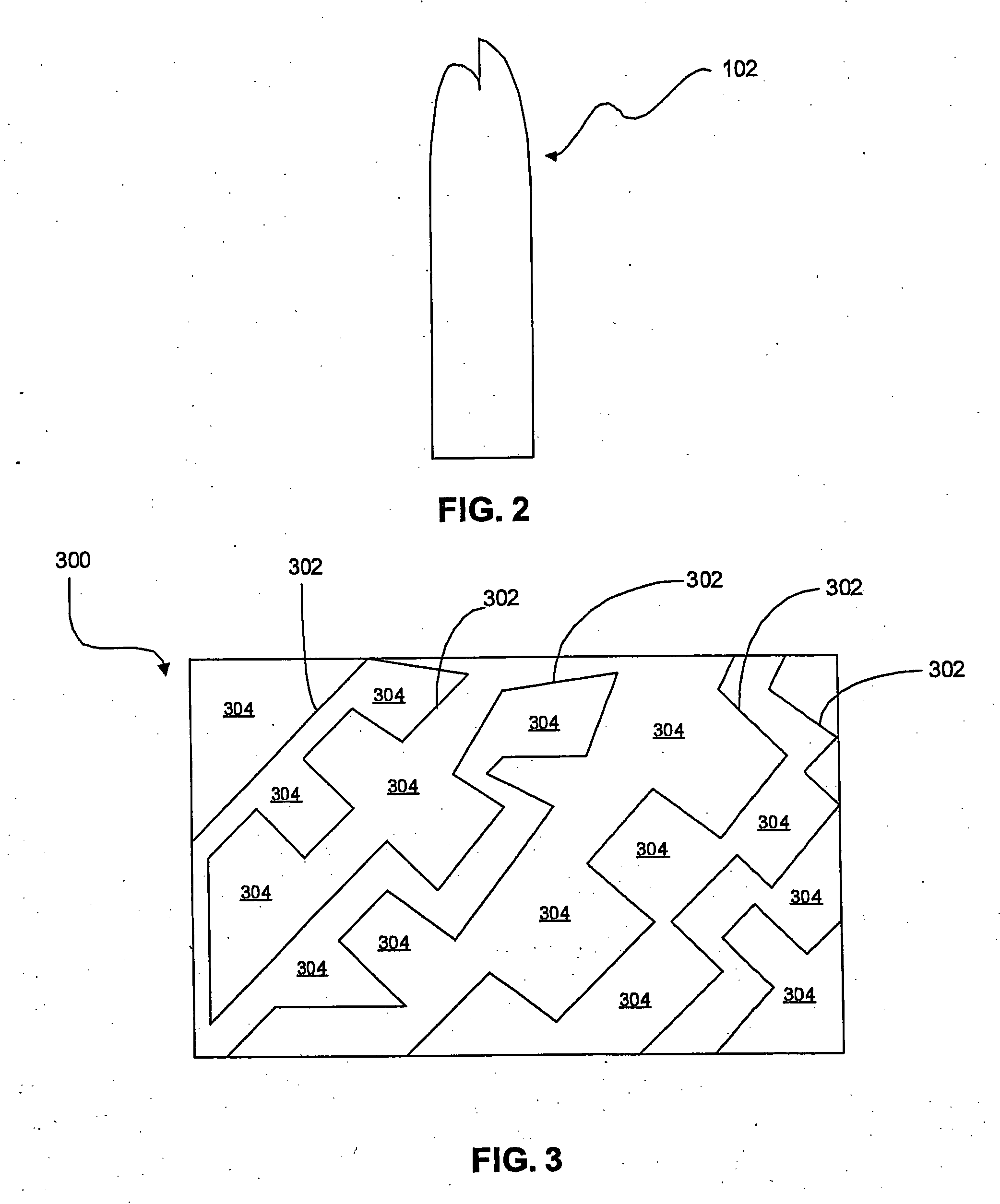

[0019] As illustrated in FIG. 1, a thermal source 100 may be used as the contouring element and be a curved torch 102 with a very consistent heated tip 102. Store bought tips 102 maybe used by altering the configuration of the tips 102 so that the tips 102 are angled to approximately a 45 degree angle. At this angle, the heat flows from the tip 102 and disburses the flame (not shown) as a side split flame, thereby allowing the leather to be curled and then bonded. FIG. 2 illustrates an enlarged view of the tip 102 of the heat source 100 configured at a 45 degree angle. Because of the nature of the composition of leather hide, it is easily burned if the proper tip 102 is not used by the heat source 100. As illustrated in FIG. 1, the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com