Method for manufacturing safety helmet and safety helmet manufactured with the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

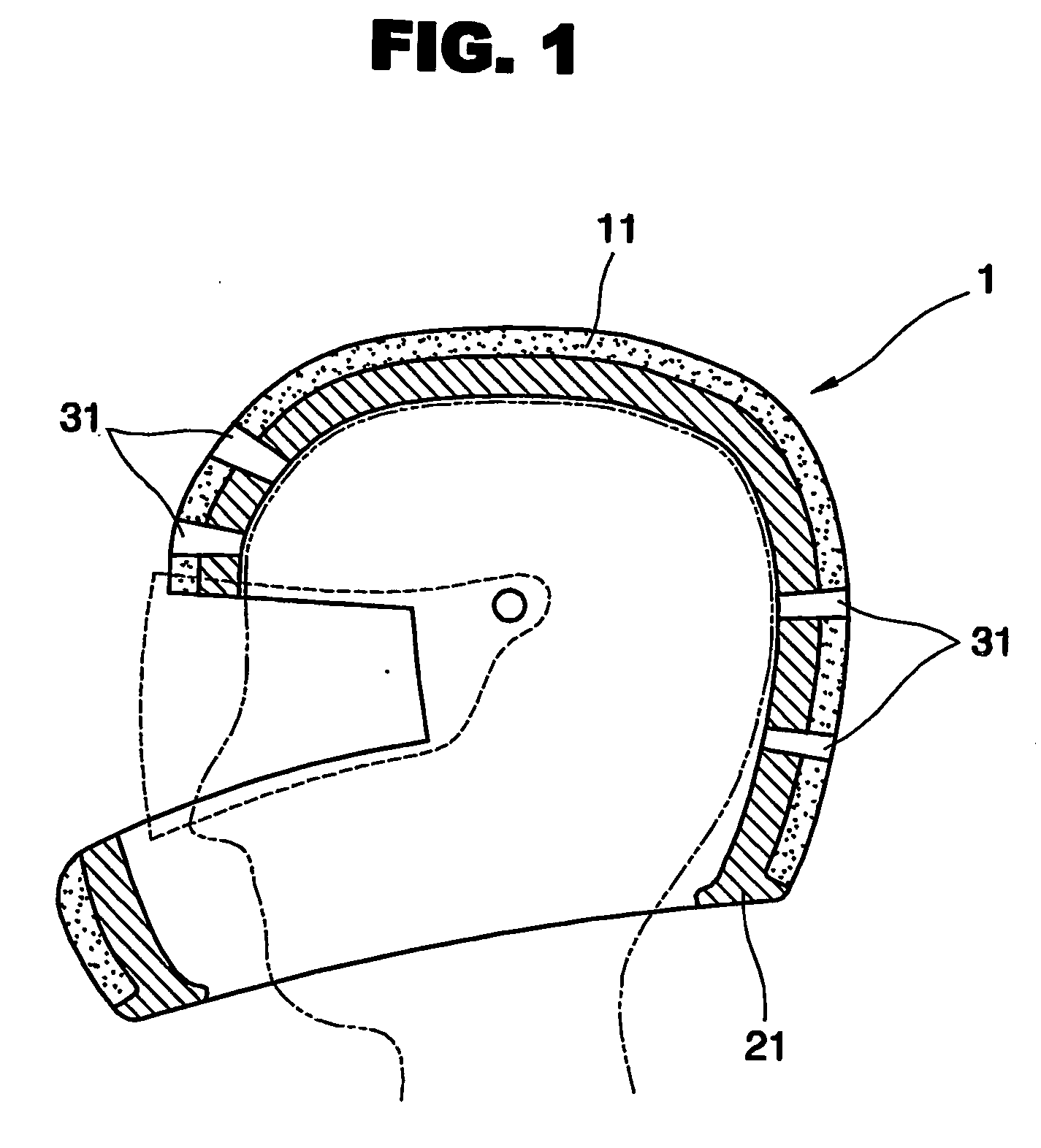

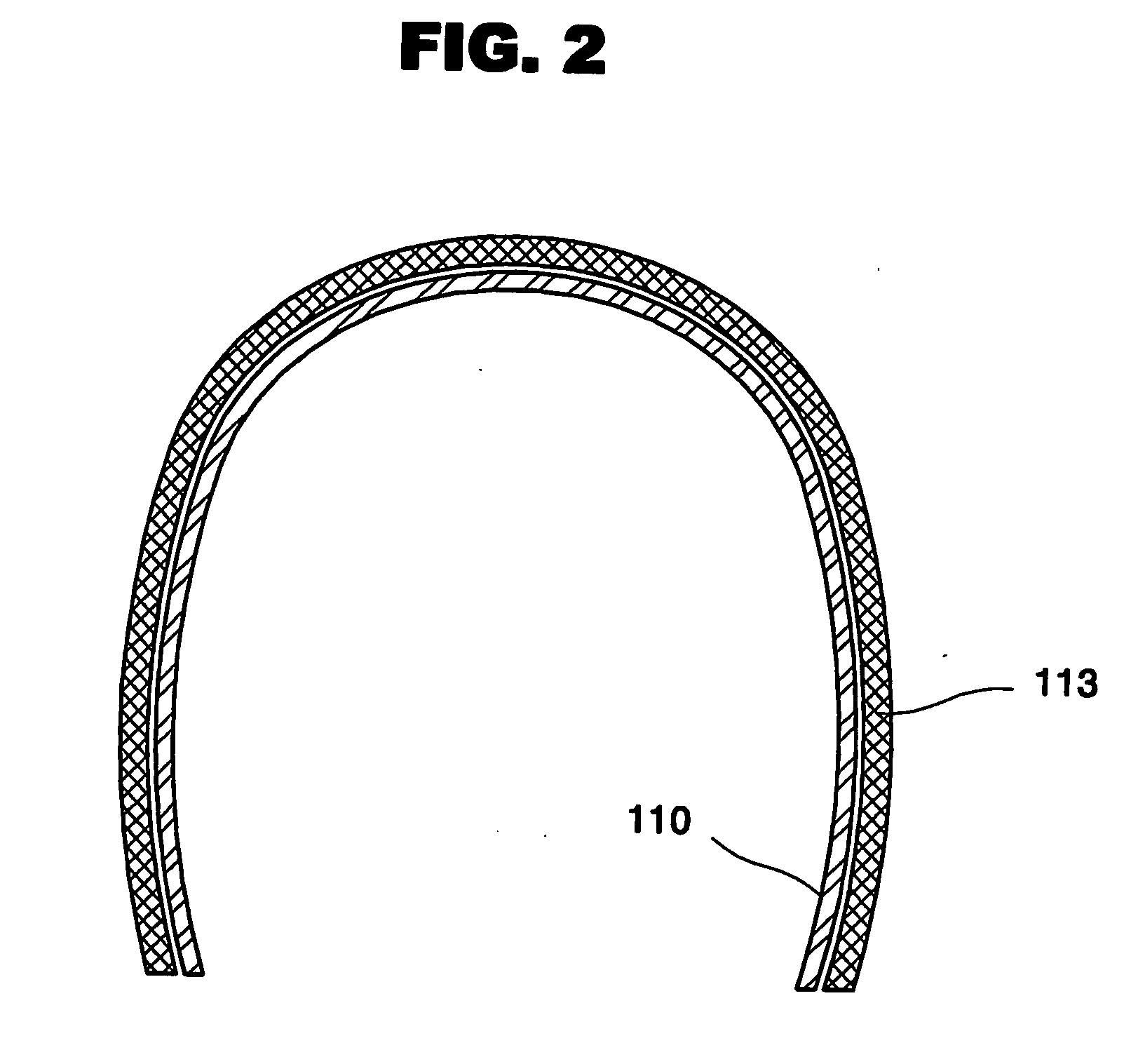

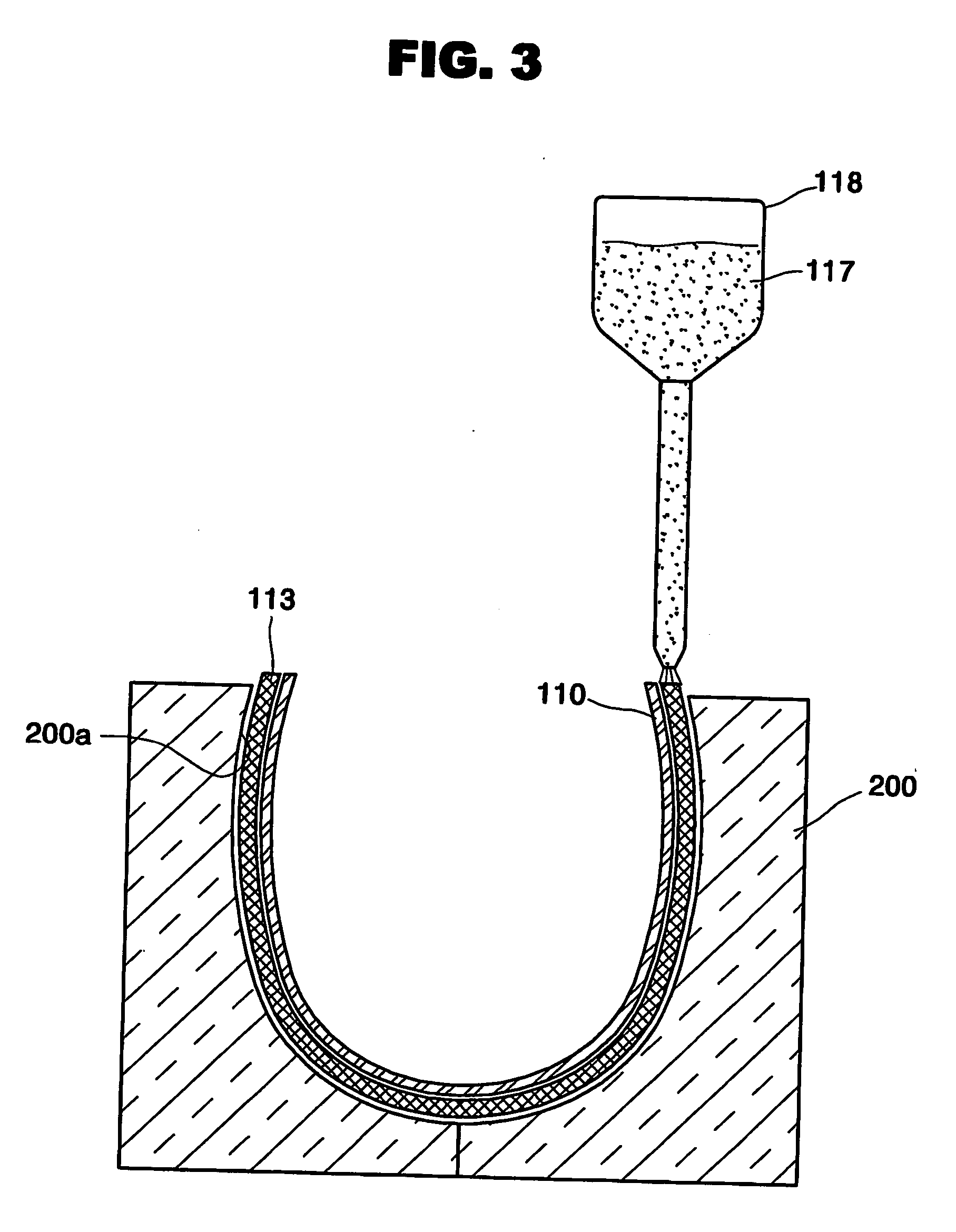

[0017] Referring to FIG. 2, in manufacturing a safety helmet according to an embodiment of the present invention, a liner 110 defining an inner space where a user's head goes and having an opening at its lower portion is molded. Next, the outside of the liner 110 is covered with a reinforced fiber sheet 113.

[0018] Since it is preferable that the liner 110 has a thickness of 1-2 mm, the liner 110 is made of a thermoplastic resin through molding. Such a molding method is widely known to those skilled in the art, and thus a description thereof will be omitted. The thermoplastic resin for the liner 110 may be a resin such as polyethylene resin, polystyrene resin, polybutyleneterephthalate resin, polyvinylchloride (PVC) resin, polymethylmethacrylate (PMMA) resin, acrylonitrile-butadiene-styrene (ABS) resin, polycarbonate resin, or nylon resin.

[0019] The reinforced fiber sheet 113 is formed using a textile or a non-woven fabric made of high-strength fiber and high elastic fiber. The rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com