Backpack frame

a frame and backpack technology, applied in the field of backpacks, to achieve the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

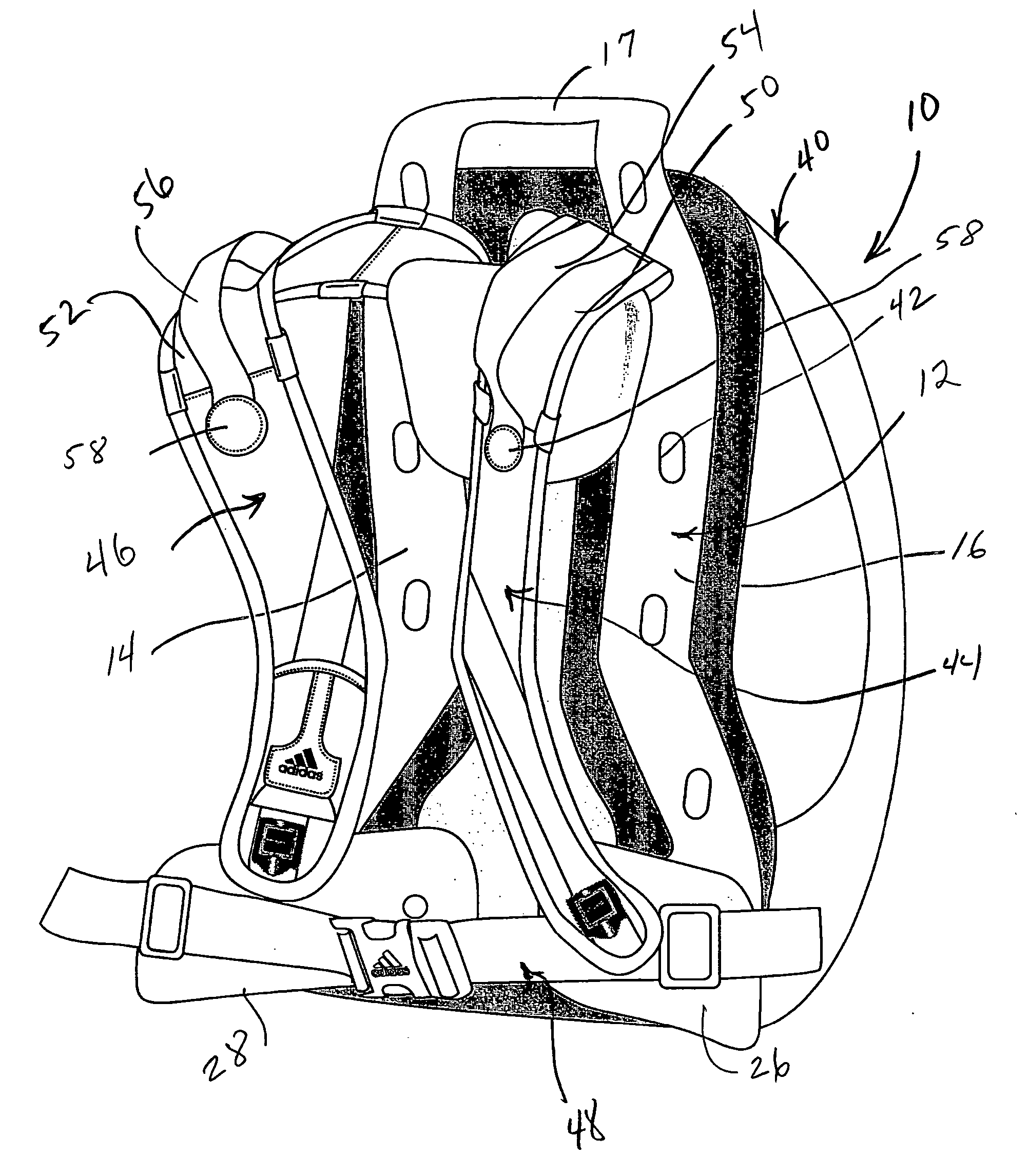

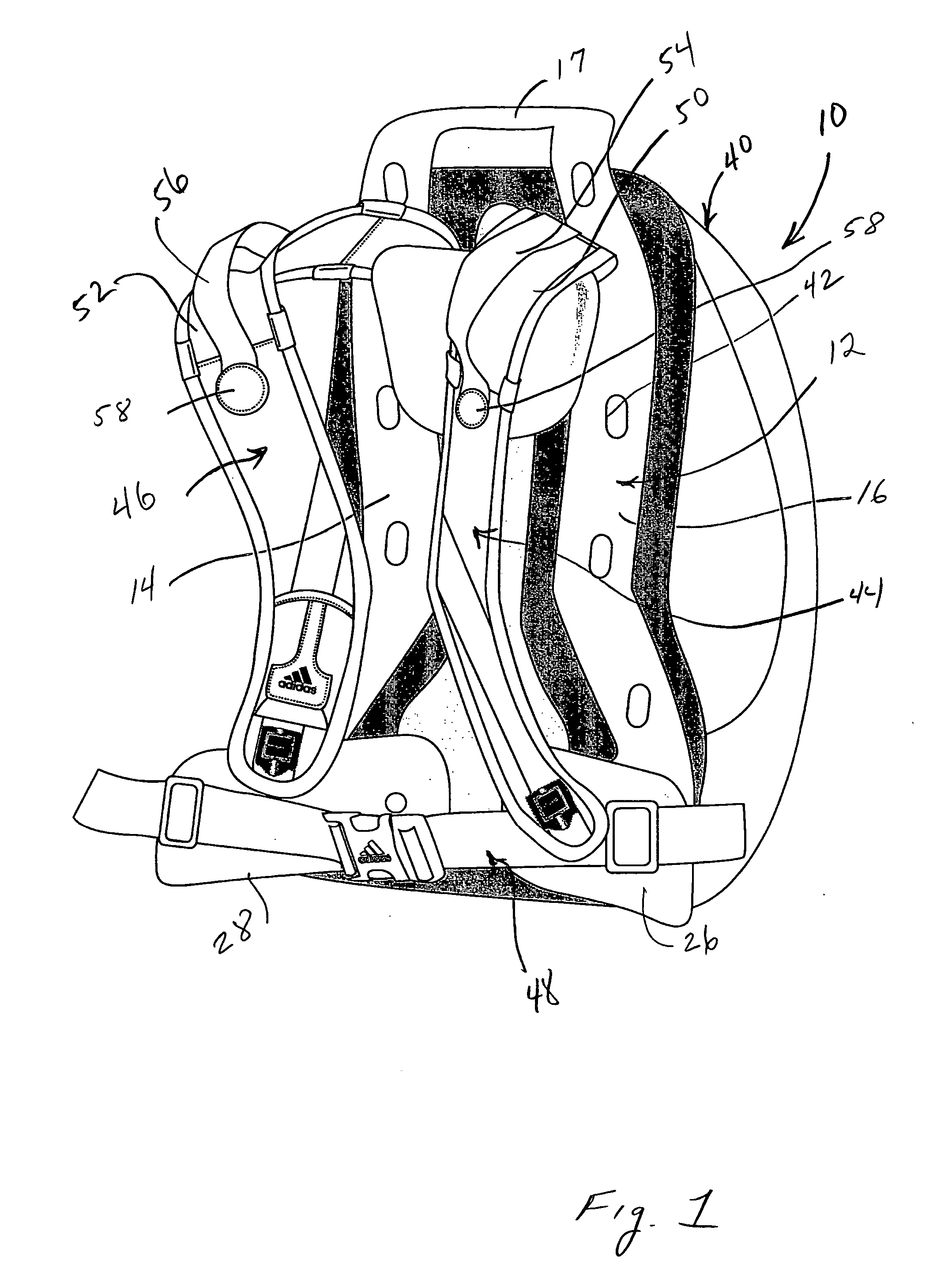

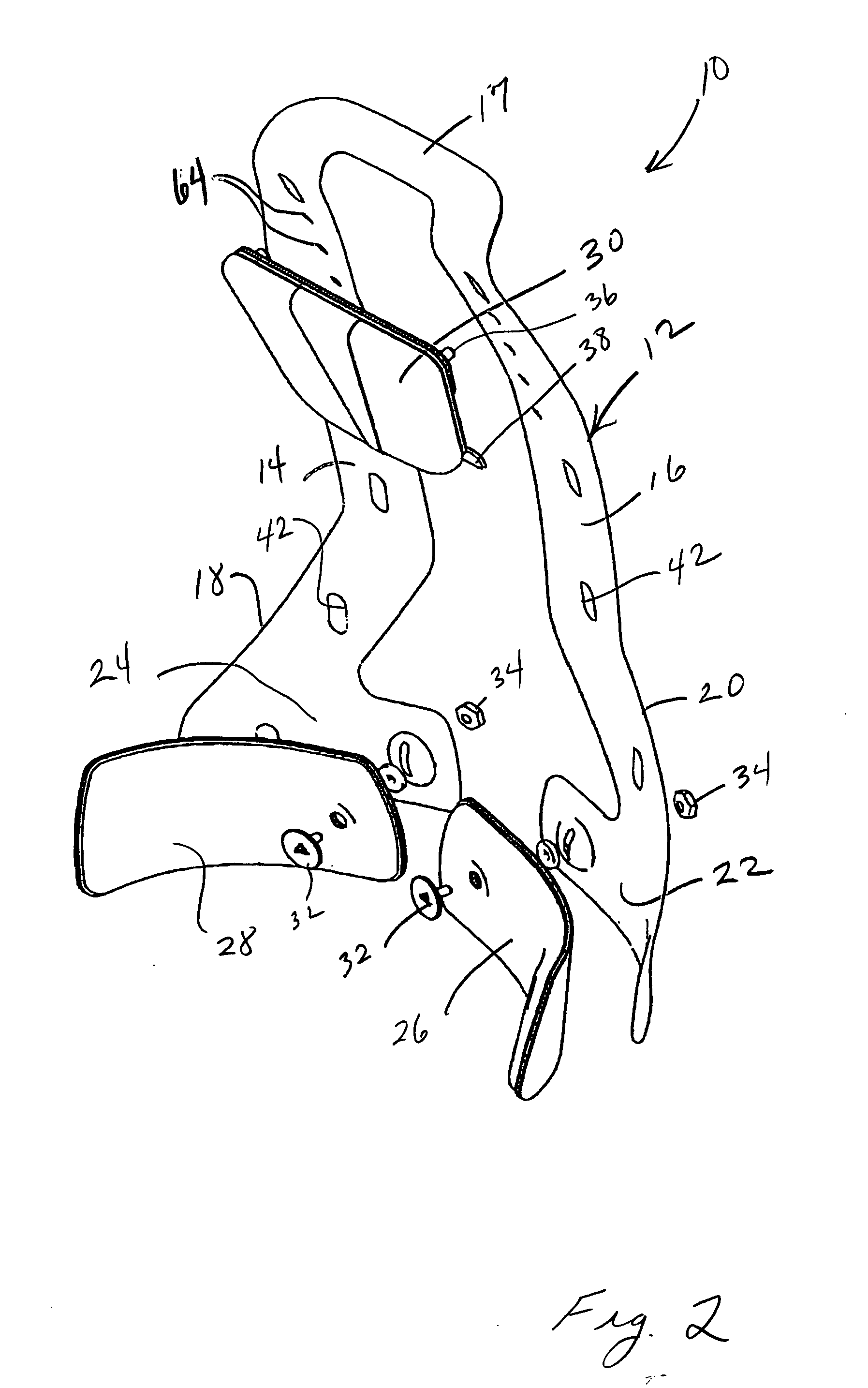

[0018] Referring now to the drawings, and first to FIG. 1, shown generally at 10 is a backpack constructed in accordance with the invention summarized above. The backpack has a forked frame, indicated generally at 12. The frame has two curved flat members 14, 16 that are connected together by a handle portion 17. Referring now to FIG. 7, which is a back view of the frame 10 disconnected from the pack or packsack 40, the lower portions of the flat members 14, 16 flare outwardly as indicated at 18, 20, respectively.

[0019] As is best seen in FIG. 2, the lower-most region of the outwardly flaring parts or frame regions 18, 20 are lumbar-supporting areas or portions, indicated at 22, 24, respectively. Attached to these areas are two lumbar pads 26, 28. Similarly, a scapular pad 30 is connected to the flat members 14, 16 near the handle portion 18. The connection of the pads 26, 28, 30 to the frame 12 can be done in different ways. In the embodiment illustrated here, the connection is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com