Multifunction pouring spout with handle

a multi-functional, canning technology, applied in the direction of flexible containers, pliable tubular containers, packaging, etc., can solve the problems of aggravated paint running down the side of the can, undesirable paint smears on walls, floors, furniture and other items, and virtually impossible to pour paint out of the can into a paint tray or other container, so as to prevent the dripping of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

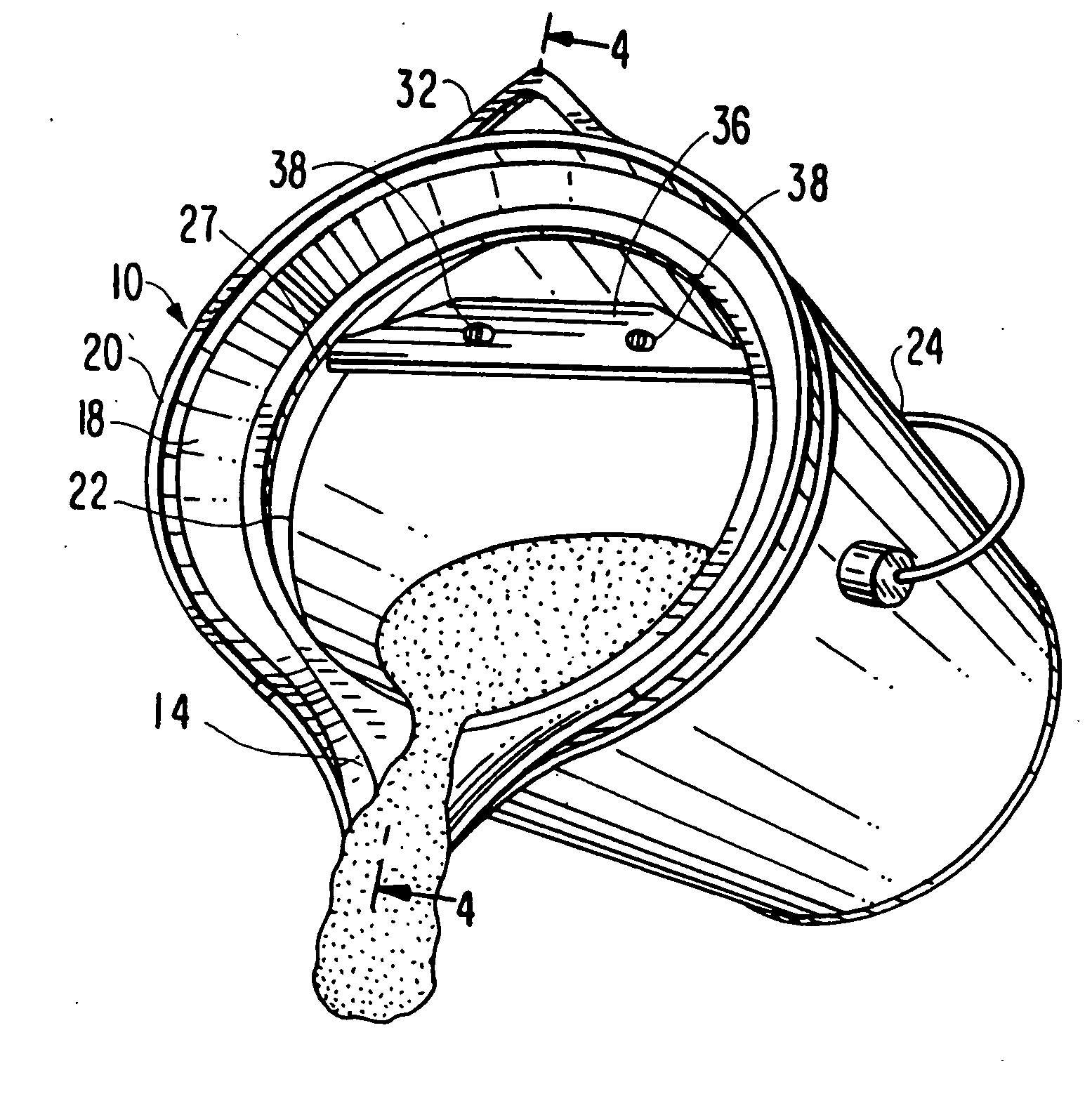

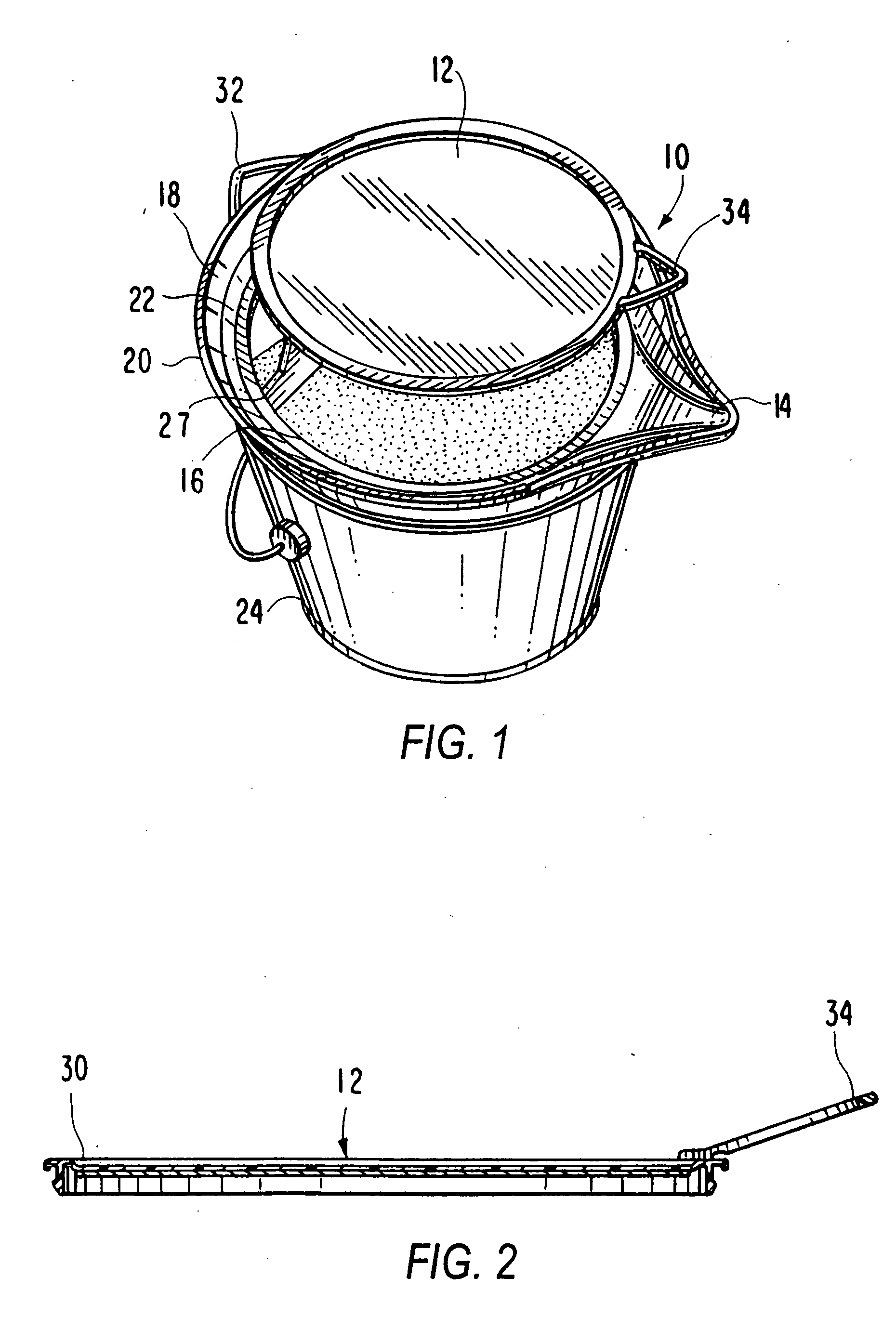

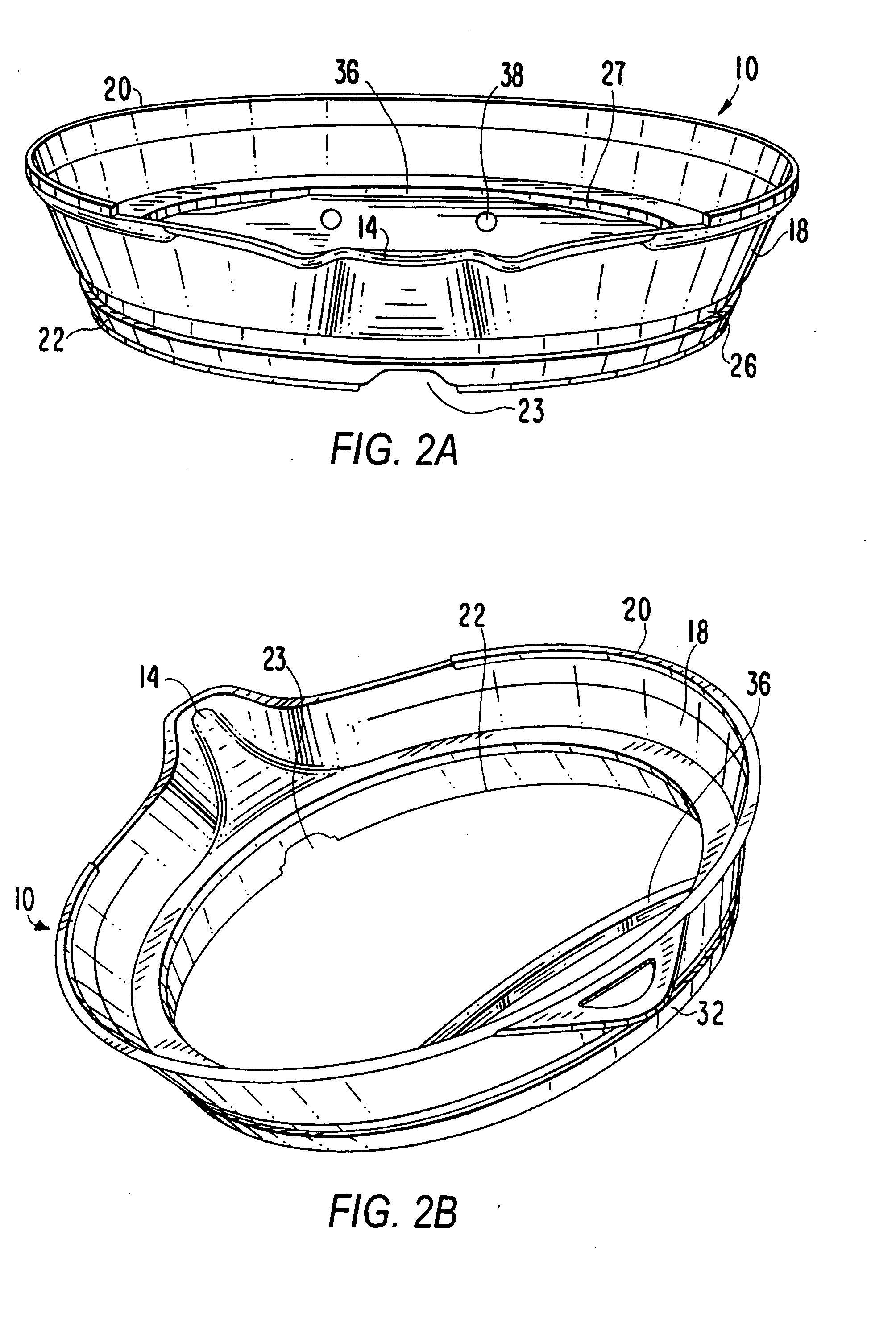

[0042] Referring to the drawings, FIG. 1 depicts a preferred embodiment of the inventive pouring spout (10) having a removable insert or lid (12). Each spout (10) also has a mouth (14), a central circular opening (16) and a lateral surface which forms a wall (18) having an upper edge or rim (20) and a lower edge or rim (22). Preferably, the lateral surface proceeds at an angle greater than ninety degrees from horizontal, such that the wall (18) that is formed inclines outwardly and upwardly from the center and lower edge (22) of the spout (10). Of course, the lateral surface may run at an angle that is ninety degrees or less from a horizontal surface of a container as well. In addition to forming the wall (18) of the spout (10), the lateral surface also forms a mouth (14). The mouth, (14) extends outwardly beyond the perimeter of the wall (18) forming a channel out of which liquid is poured from its container. As the channel extends away from the center of the spout (10), it gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com