Assembly containing stacks of a web of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

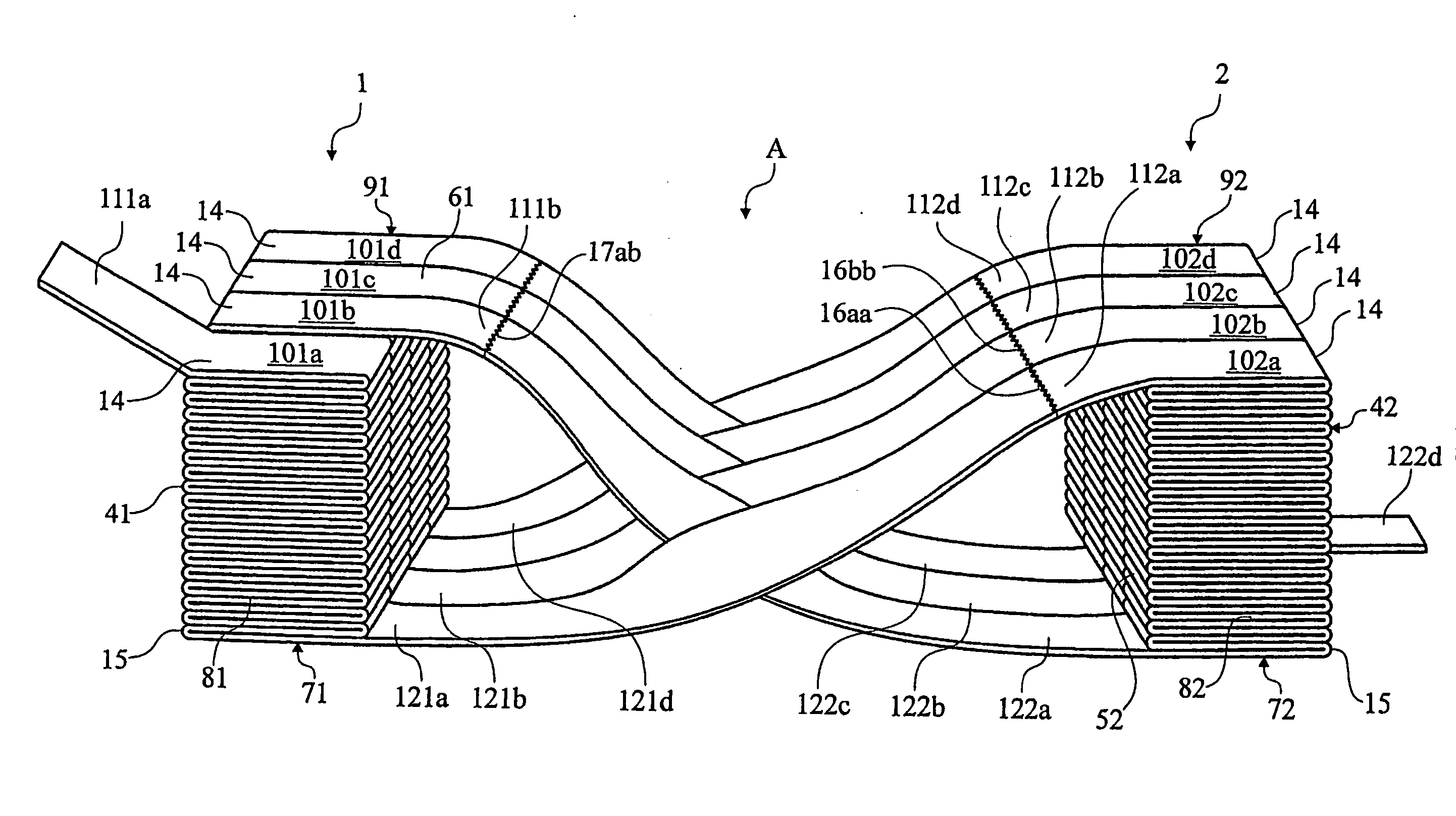

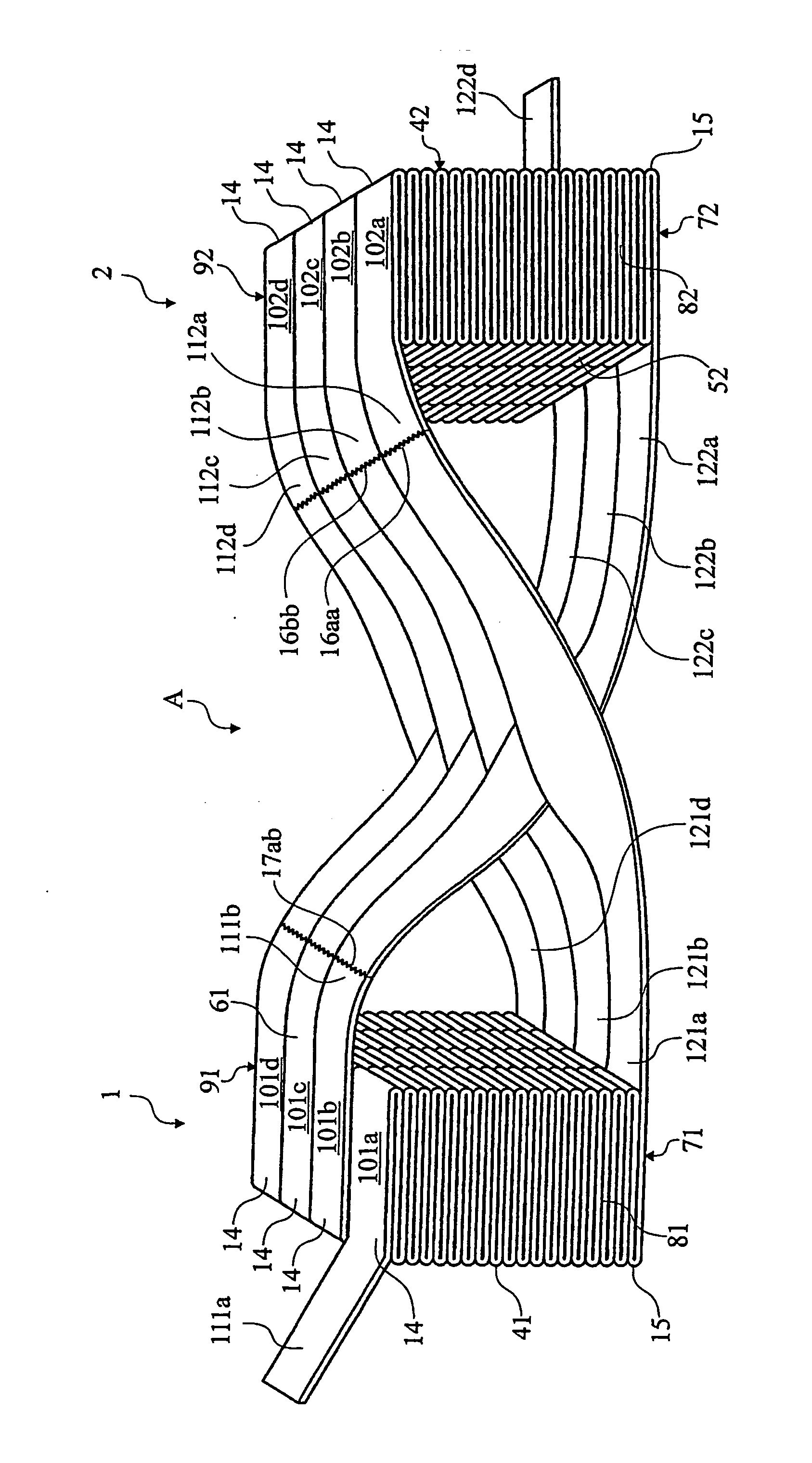

[0026] A prototype embodiment of an assembly A according to the invention is shown in the drawing. It consists of two essentially parallelepipedic units, in this text referred to as a first pack 1 and second pack 2, the shape and size of which may be adapted to international standards for transportation. Each pack consists of a plurality (more than two; equally many in each pack) of parallel stacks abutting one another, of strip-shaped material, which is folded in a fanfold manner between the ends of the stacks. With reference to the direction of feeding the strip material from the packs, the first folds in the stacks are designated 14, while the last folds are designated 15.

[0027] The first stack of the first pack 1 is designated 101a, the second stack is designated 101b, etc. In the illustrated case, the case contains four stacks. The last stack of the first stack is designated 101d. In the second pack 2, the stacks are correspondingly designated 102a, 102b, 102c and 102d in orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com