A split-type tool setting instrument installation and adjustment device and its positioning method

A technology of adjusting device and tool setting instrument, which is applied in the direction of feeding device, automatic control device, manufacturing tools, etc., can solve the problems of dimensional accuracy fluctuation, high labor cost, workpiece scrapping, etc., and achieve error reduction, accurate position, and elimination of tool parameters the effect of the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

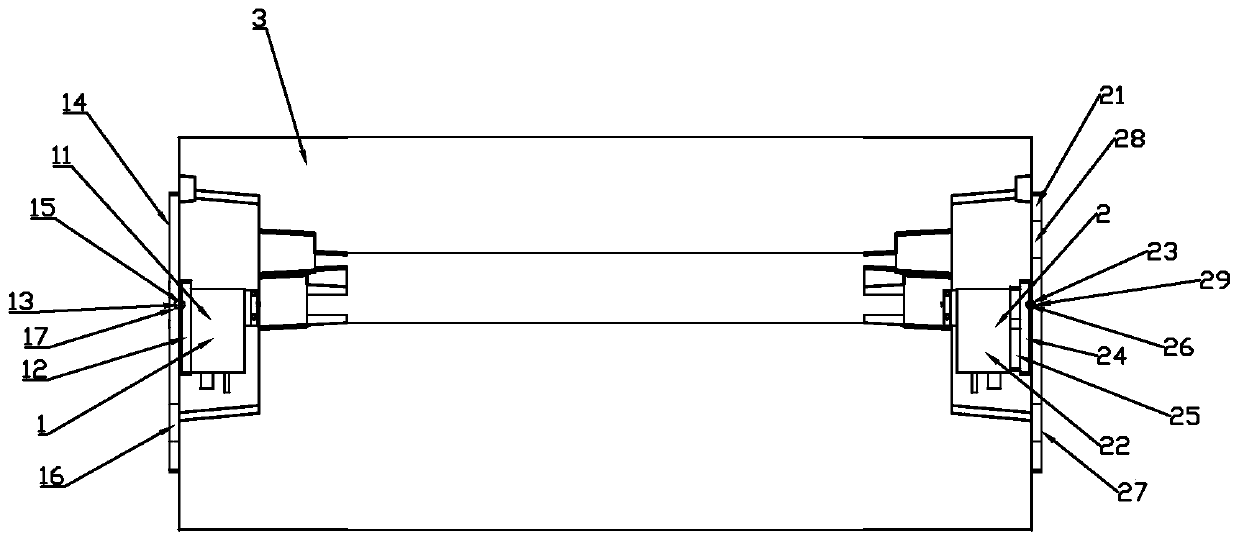

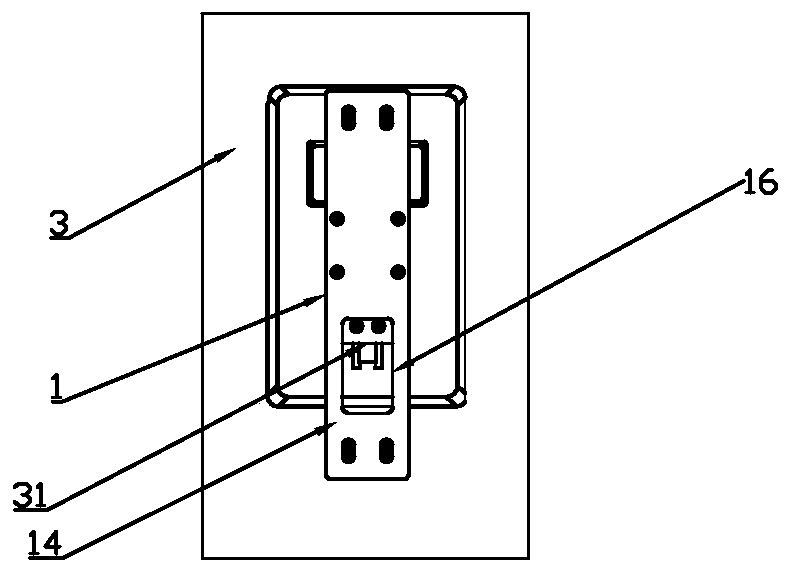

[0037] Such as Figures 1 to 3 As shown, a split-type tool setting instrument installation and adjustment device includes a tool setting instrument transmitting unit 1 and a tool setting instrument receiving unit 2;

[0038] The launching unit 1 of the knife setting instrument includes a launching end 11 of the knife setting instrument, a launching end adjusting plate 12, a steel ball 13 at the launching end and a supporting plate 14 at the launching end, and the launching end 11 of the knife setting instrument is connected to the launching end adjusting plate 12, the launch end steel ball 13 is placed in the connection hole I15 outside the launch end adjustment plate 12, and the launch end support plate 14 is connected to the outside of the launch end adjustment plate 12;

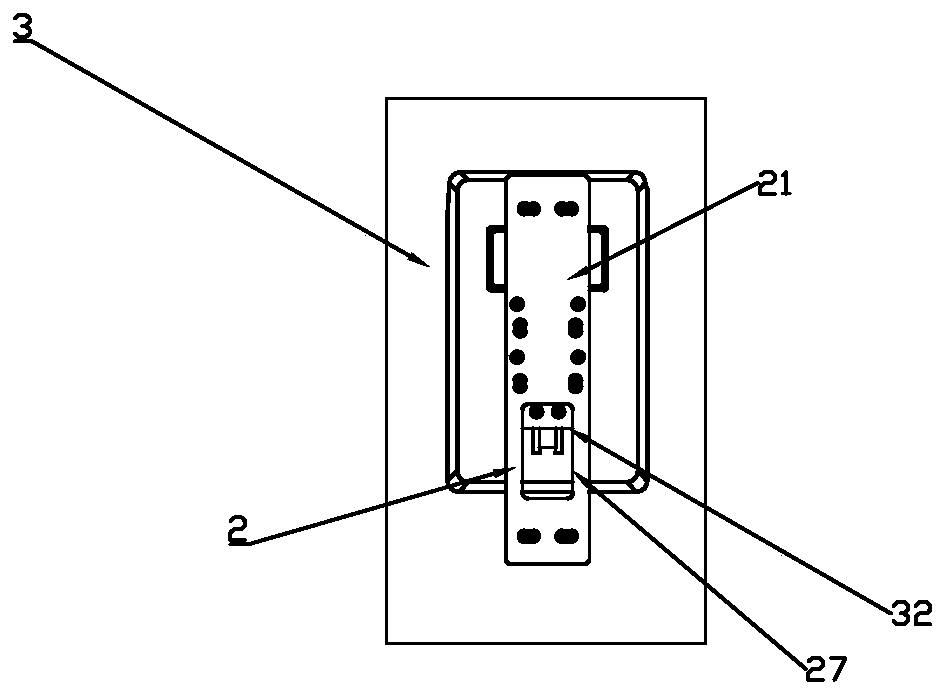

[0039] The tool setting instrument receiving unit 2 includes a receiving end support plate 21, a tool setting instrument receiving end 22, a receiving end steel ball 23, a receiving end adjustment plate 24...

Embodiment 2

[0049] Such as figure 1 , figure 2 with Figure 4 As shown, a split-type tool setting instrument installation and positioning method for adjusting the device, the split-type tool setting instrument installation and adjustment device, the positioning method includes the following steps:

[0050] S1: Fix the launcher 11 of the tool setting instrument to the inner side of the launcher adjustment plate 12 by screws;

[0051] S2: Place the launch end steel ball 13 in the connection hole I15 on the outside of the launch end adjustment plate 12, take the launch end steel ball 13 in the connection hole I15 as a reference, and place the connection hole on the inside of the launch end support plate 14 III17 is engaged on the outer side of the launching end steel ball 13, and the launching end supporting plate 14 is connected to the outer side of the launching end adjusting plate 12 with screws, and the launching end steel ball 13 is arranged in the connection hole I15 and the In the...

Embodiment 3

[0063] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a vertical waist-shaped groove I16 is arranged on the support plate 14 of the transmitting end, and a horizontal waist-shaped groove 28 is arranged on the upper end of the support plate 21 of the receiving end. The lower end of the end support plate 21 is provided with a vertical waist-shaped groove II 27 .

[0064] Preferably, the transmitting end 11 of the tool setting instrument is a T55AD1030-BD-650 laser transmitter, and the receiving end 22 of the tool setting instrument is an IS0103 laser receiver.

[0065] Preferably, the connecting piece I31 passes through the vertical waist-shaped groove I16 on the launch end support plate 14 to connect the launch end support plate 14 to one side of the machine bed 3;

[0066] The connecting piece II32 connects the receiving end support plate 21 to the other side of the machine bed 3 through the vertical waist-shaped groove II27 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com