Method for monitoring yarn quality in an optical detector of yarn quality and optical detector for performing the method

A technology for optical detectors and yarn quality, applied in the direction of material analysis through optical means, scientific instruments, optical devices, etc., can solve the problems of different sensitivity of individual optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

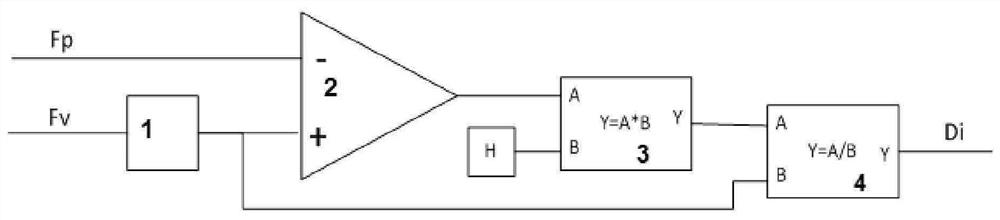

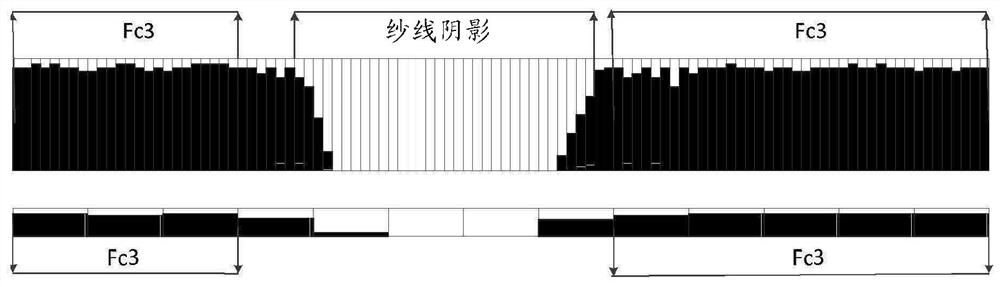

[0023] figure 2 Unsaturated and fully irradiated optics are shown, where the black color corresponds to the amount of energy falling on the optic. Due to the fact that it is an optical element with an analog output, this optical element must not saturate even during the maximum illuminance of the radiation source. M is the maximum value of the analog signal that can be provided by the optical element at its output if the optical element is illuminated with such intense light that it will be in so-called saturation. Fv is the resulting value of the simulated signal provided by an individual fully irradiated optical element not shaded by the yarn. The figure on the right shows the same optic partially obscured by yarn, where Fp is the output value of the analog signal during partial shading by the yarn. The energy loss caused by the partial shading of the optical element by the yarn is determined by the difference Fv - Fp.

[0024] However, it must be taken into account t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com