[0004] An object of the present invention is to provide a gripping device that exhibits better behavior in case of crashes and collisions.

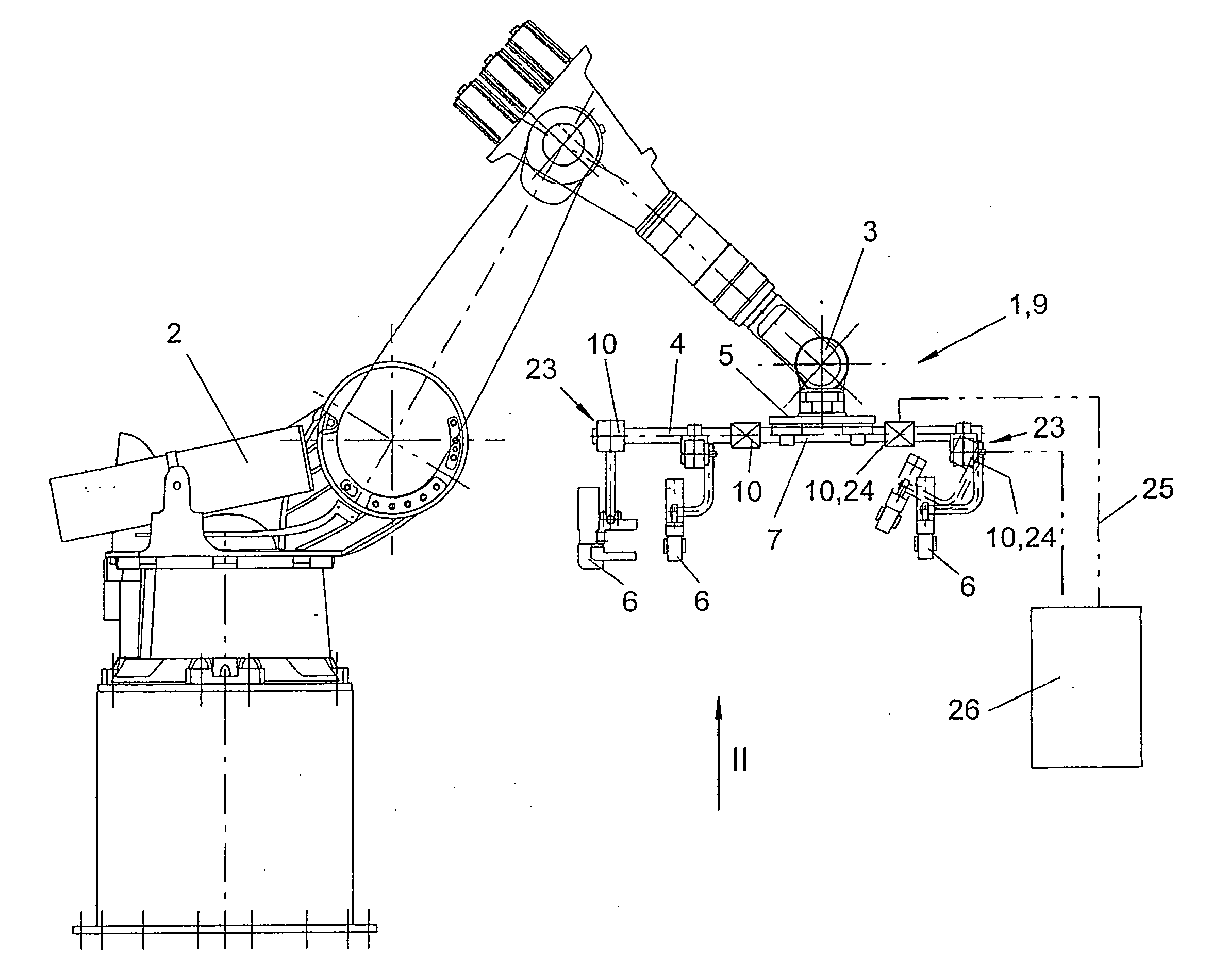

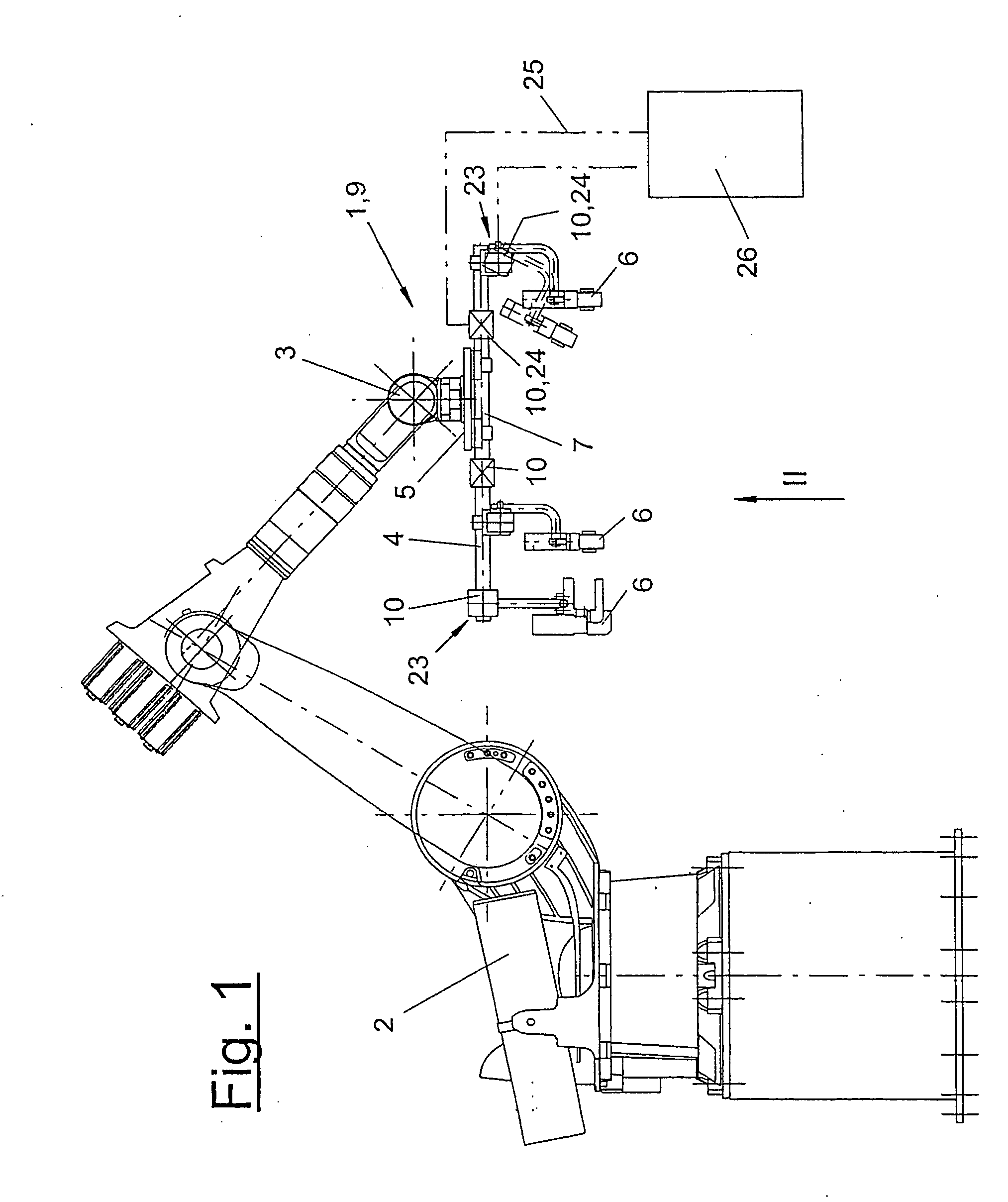

[0005] According to the invention, a

manipulator-guided gripping device is provided for workpieces such as body parts in a body shell. The gripping device has a plurality of device parts and a safety means for detecting changes in geometry with at least one deflectable safety device at the device parts. The deflectable safety device is provided at the various components or parts of the gripping device. The safety device is preferably present as multiple devices to provide the

advantage that it makes possible the deflection of the colliding parts of the gripping device in case of a

crash or collision, as a result of which plastic deformations and other damage are avoided on the gripping device. Due to the deflected position, it is, moreover, optically signaled to an operator that a collision has taken place. In addition, suitable detectors or sensors may be present at the deflectable safety device, which detect a deflecting movement and report it in a suitable manner, for example,

signal it to a

process control, automatically trigger an alarm or the like.

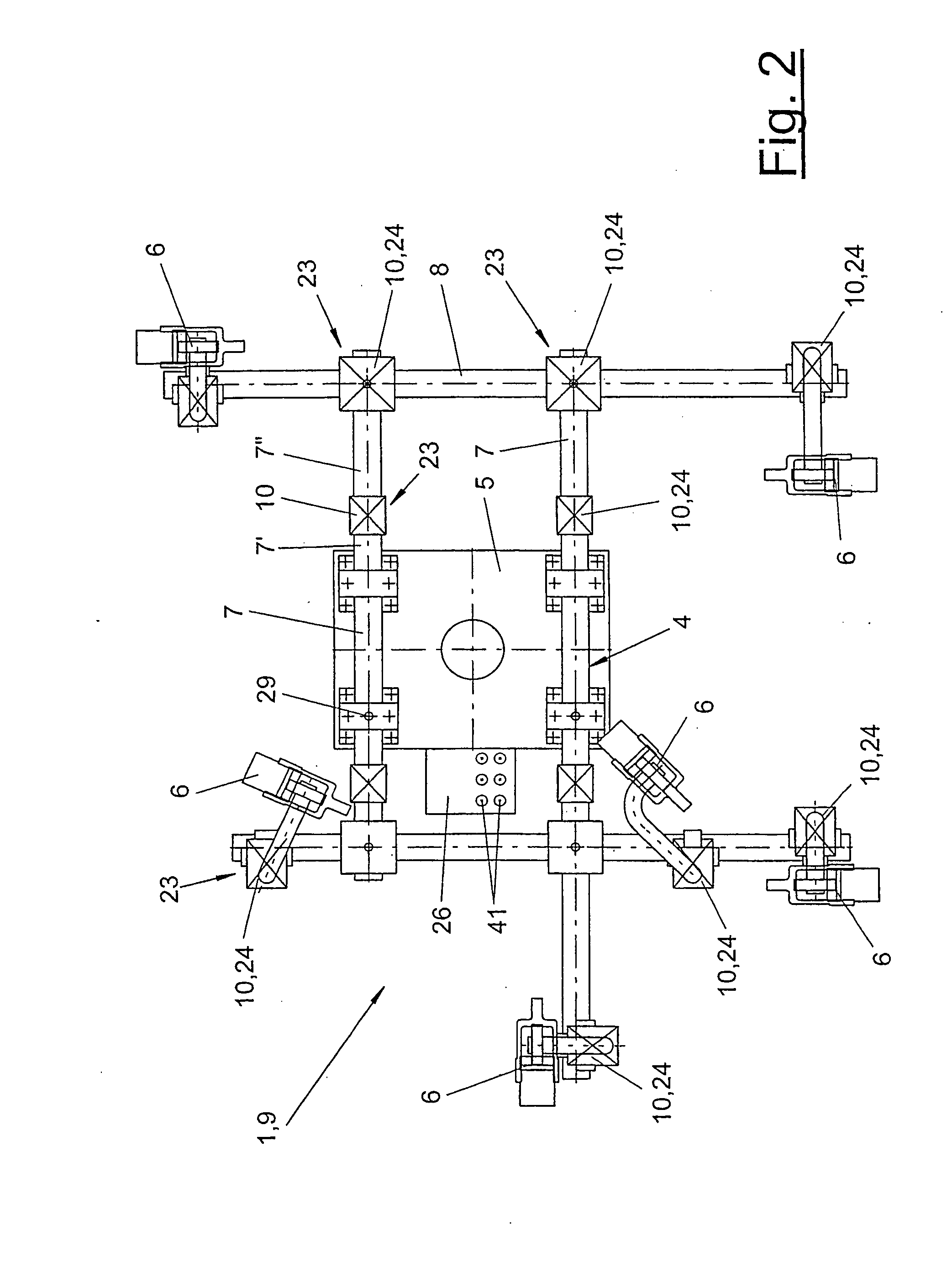

[0006] The deflectable safety device is preferably arranged at a connection point between the different device parts of the gripping device. The device parts, for example, frame tubes, may also be divided, in which case a deflectable safety device is arranged between the tube sections. The deflectable safety device may be located as a result at the points of the gripping device that have been shown by experience to be loaded most heavily and are also critical. Depending on the geometry of the gripping device, the positions of the different deflectable safety devices are selected to be such that the colliding device part can be deflected immediately in case of a collision, and deformations and damage are avoided in this part as well as on the other components of the gripping device.

[0007] The deflectable safety device may connect the device parts with clamping and frictional connection or with deflectable positive-locking connection. An adjusting means makes possible the reproducible positioning of the device parts in the initial device and also during the repositioning after a

crash. The

detector may be a part of the adjusting means. The moving device part can again be returned into its desired position after the deflection. As a result, the gripping device can continue to be used without complicated measurement and resetting.

[0008] If the deflectable safety device is provided with a locking element for positive-locking guiding, it is thus also possible to exactly define the desired position and to position the device parts. The locking element is preferably spring-loaded, and the overload or load threshold generated by collision, beginning from which deflection is to take place, can be set by means of the spring mounting. The deflectable safety device is rigid and dimensionally stable below this threshold, so that it does not compromise the function and the geometry of the gripping device. The holding frictional force can be set by a controlled clamping connection in case of a frictionally engaged connection.

[0009] From a design viewpoint, the deflectable safety device may have various designs. It preferably comprises at least two safety device parts, which may be designed, for example, as a sphere each with a socket surrounding it or as disk mounts with parallel working surfaces. A plurality of locking elements, which may be designed, for example, as spring-loaded balls or the like, are preferably located between the safety device parts. By selecting the geometry of the safety device parts and of the locking elements correspondingly, the deflectable safety device can make possible deflection along one or more defined axes in case of a collision.

Login to View More

Login to View More  Login to View More

Login to View More