Vent assembly

a technology of vent assembly and vent fitting, which is applied in the direction of valve construction, lighting and heating apparatus, heating types, etc., can solve the problems of deformation of the visible surface of the plated surface the relatively complex form of the vent fitting, and the deformation of the appearance of the plated fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

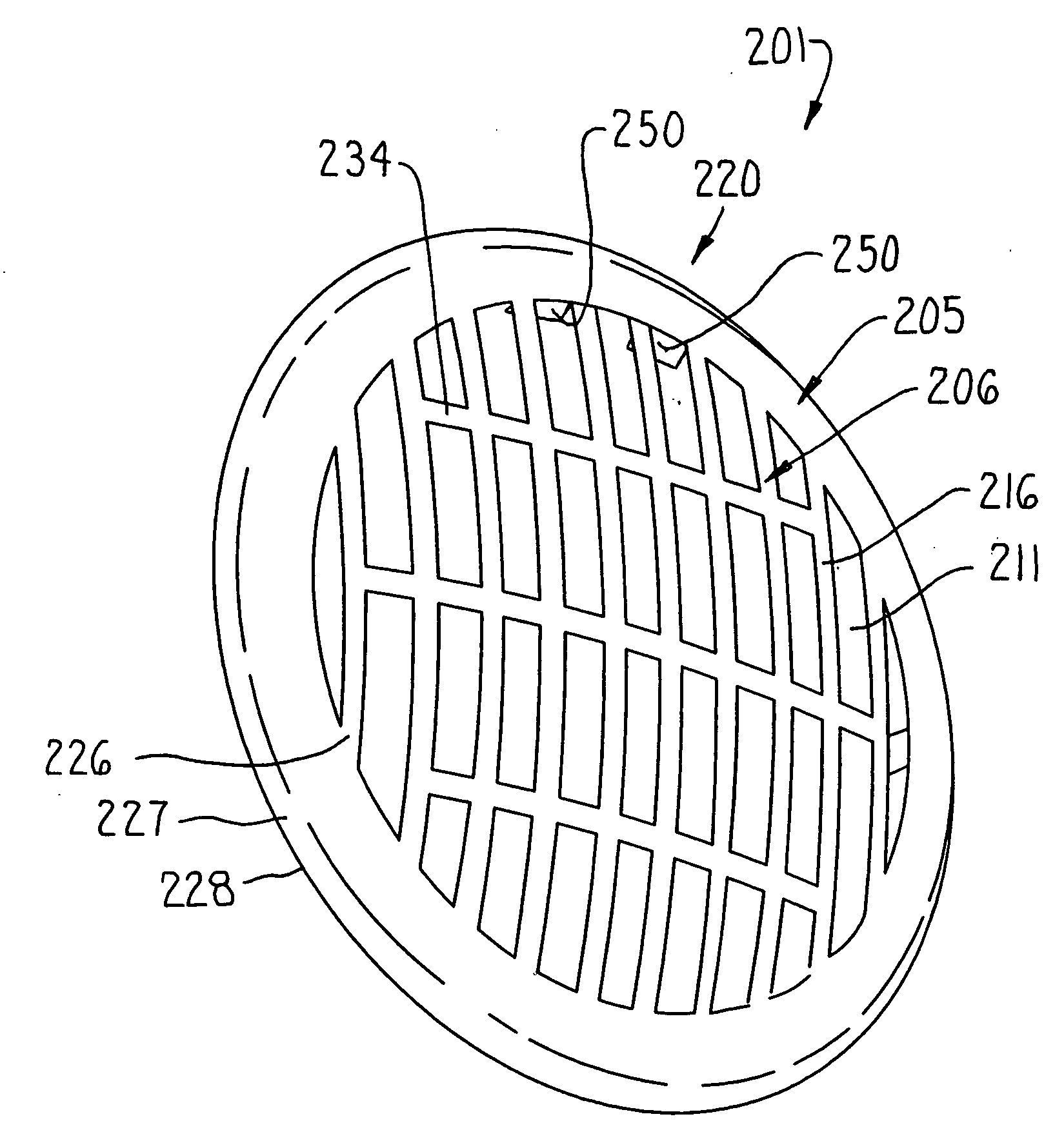

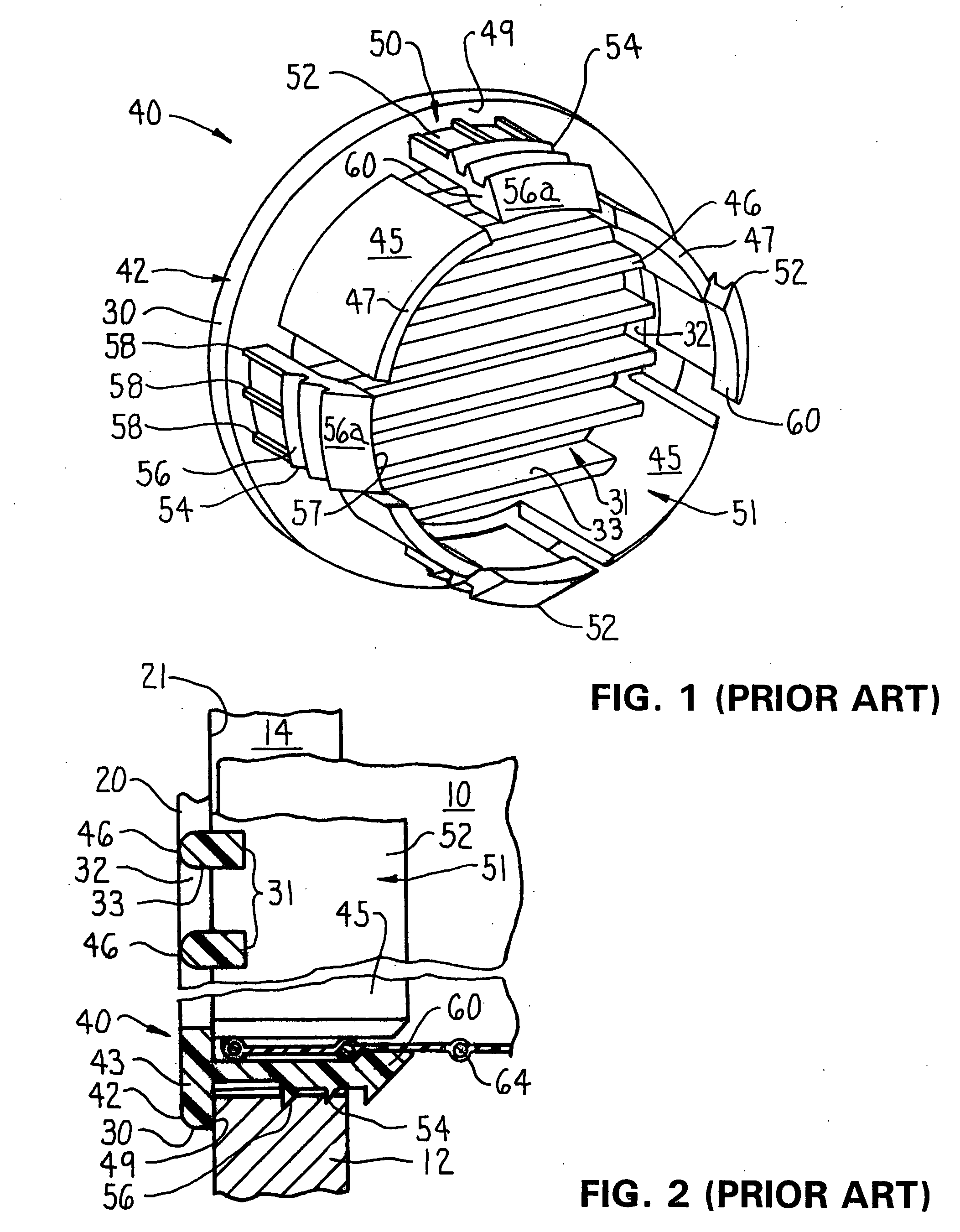

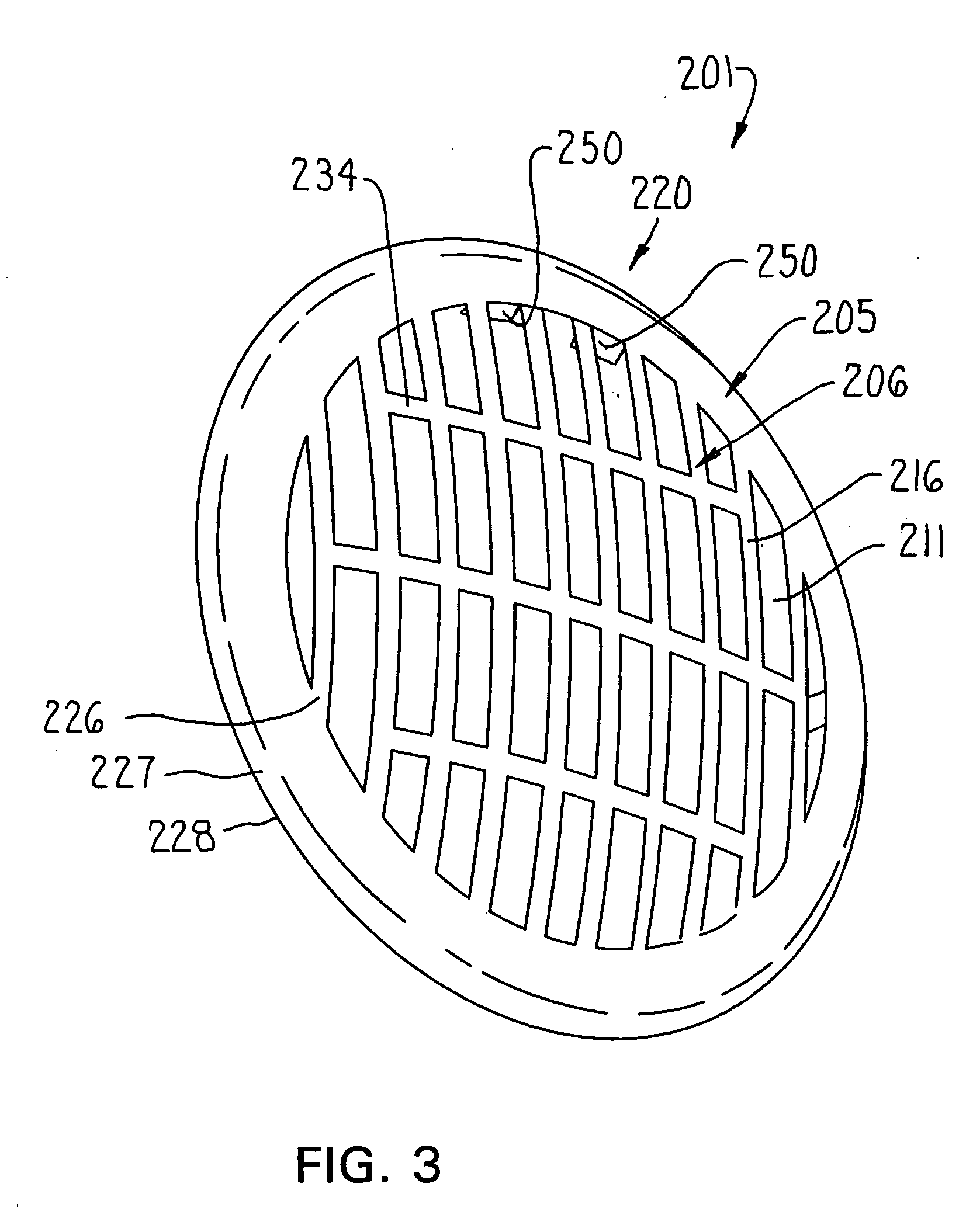

[0021] A vent 40 (FIGS. 1 and 2) is here formed to function as a hose fitting. The vent 40 is formed (preferably molded) of a suitable substantially rigid molded plastics material, such as nylon or polypropylene. The molded plastics vent 40 includes a radially extending head 42, here in the form of a circular face plate. The head 42 has a radially outward facing edge 30 and a continuous peripheral edge portion 43 inboard of the edge 30. The head 42 is perforated by a pattern of elongate ventilating slots 31 extending axially therethrough and laterally to the peripheral edge portion 43. The slots 31 have end walls 32 at the peripheral edge portion 43. The slots are separated by flanking straps 46 defining side walls 33 of the slots 31. The head 42 has front and back sides 20 and 21 respectively separated by the radially outward facing edge 30 and to which the slots 31 open.

[0022] The molded plastics vent 40 also has a generally tubular base 50 extending substantially coaxially from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com