Retractable brace

a technology of retractable braces and retractable brackets, which is applied in the direction of building parts, wall construction, building material handling, etc., can solve the problems of inability to adjust, wooden braces are very heavy, and the structure form can be very large and heavy, so as to avoid the effect of affecting the movement of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description is not to be taken in a limiting sense, but is made merely for the purpose of describing the general principles of the invention. The scope of the invention should be determined with reference to the claims. The present embodiments address the problems described in the background while also addressing other additional problems as will be seen from the following detailed description.

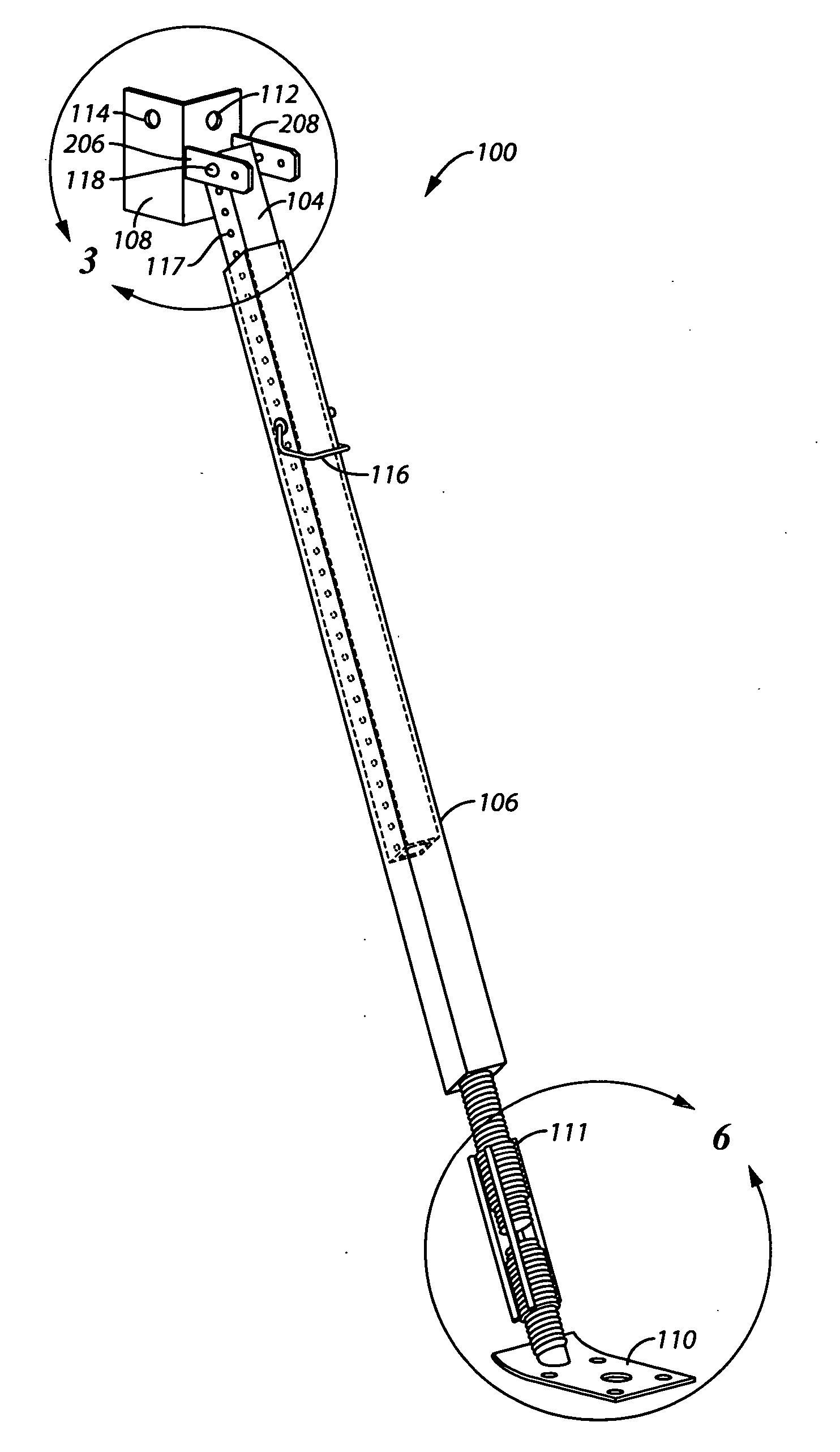

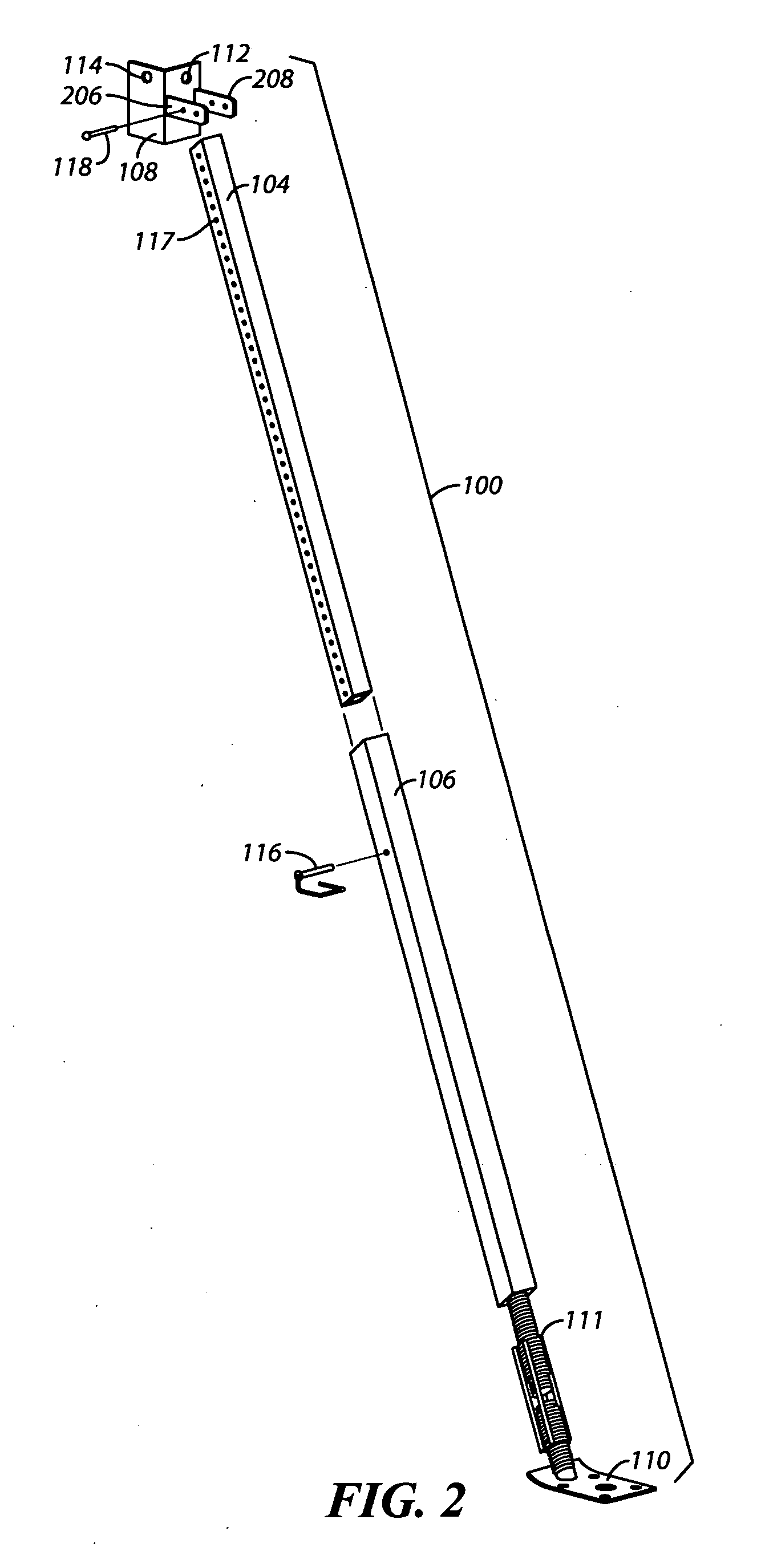

[0024] Referring to FIG. 1 a three dimensional diagram is shown illustrating a retractable brace 100 in accordance with one embodiment. FIG. 2 shows an exploded view of the retractable brace 100 of FIG. 1. As shown, the retractable brace 100 includes a telescoping portion that includes a first tube 104 and a second tube 106, a bracket 108, a foot plate 110, a swivel 111, a first bracket hole 112, a second bracket hole 114, an adjustment pin 116, and a first bracket pin 118.

[0025] The telescoping portion is pivotally coupled to the bracket 108 and is welded to the swivel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com