Dual-injector fuel injection engine

a fuel injection engine and injector technology, applied in the direction of machines/engines, electric control, combustion air/fuel air treatment, etc., can solve the problems of fuel leakage from the sealed portion, cumbersome assembly, etc., and achieve the effect of high mounting accuracy and easy maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

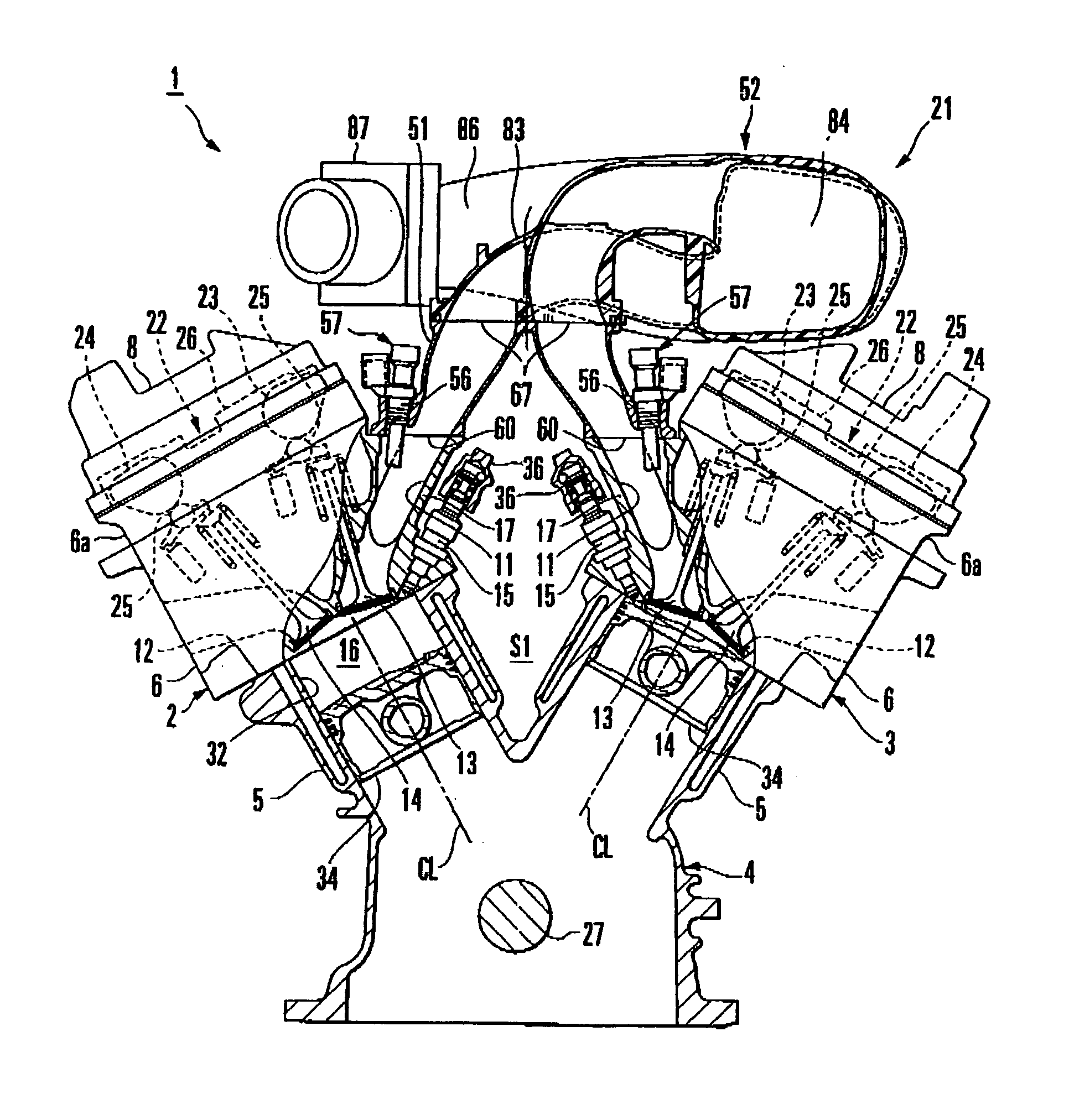

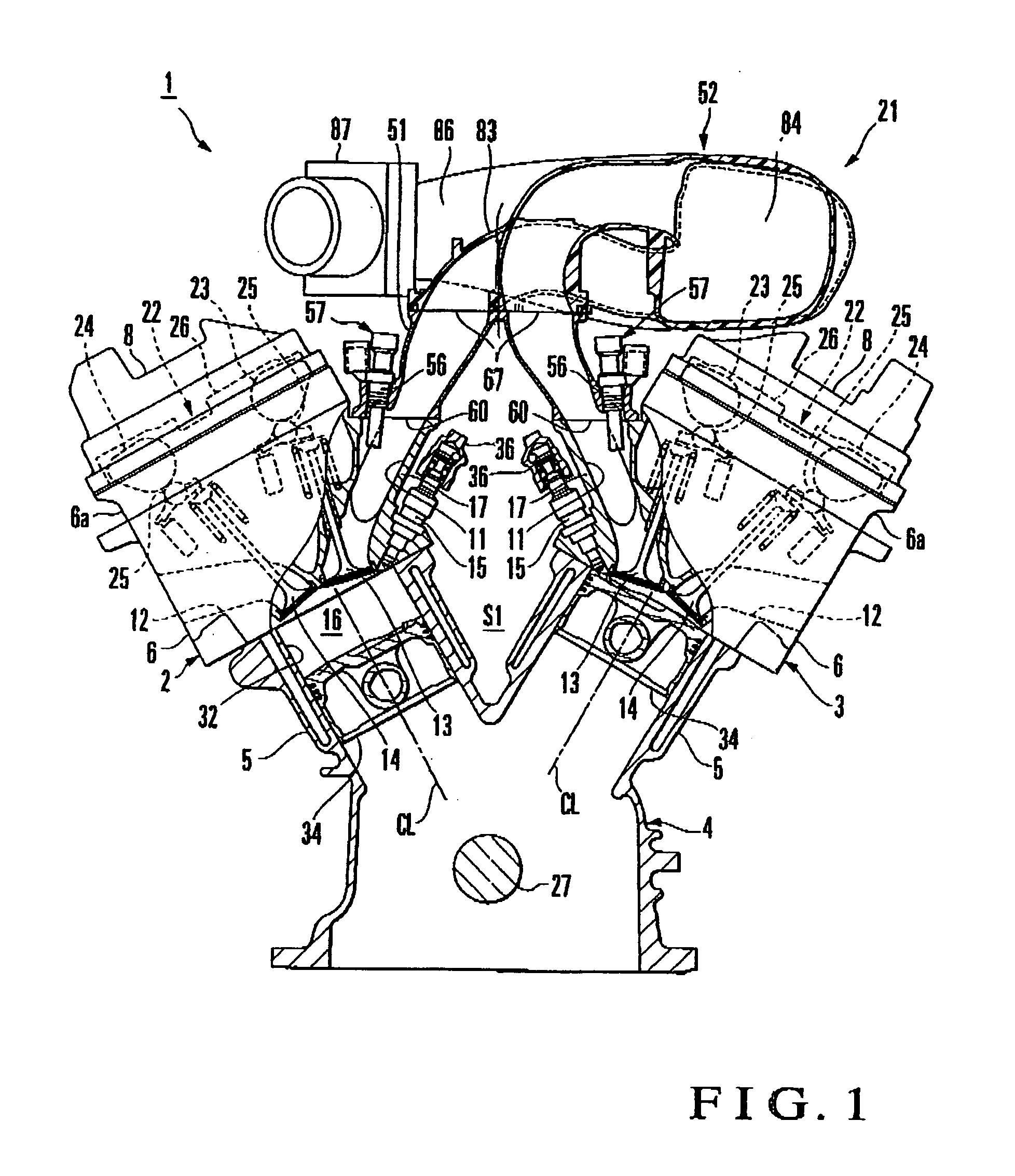

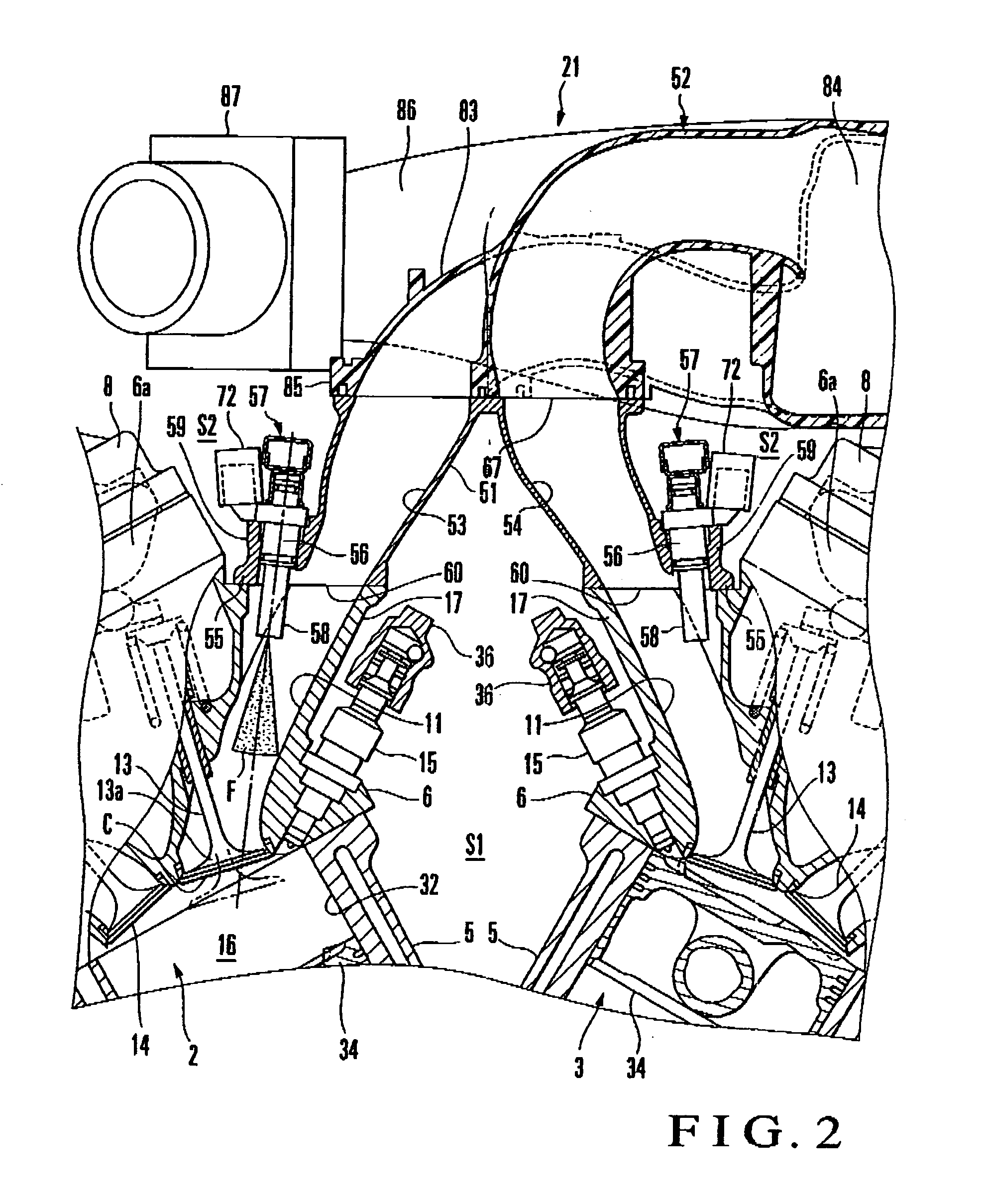

[0024] A dual-injector fuel injection engine according to one embodiment of the present invention will be described with reference to FIGS. 1 to 8.

[0025]FIGS. 1 and 2 show the main part of a dual-injector fuel injection engine according to the present invention. FIG. 3 shows a state wherein an intake manifold is mounted, and FIG. 4 shows a state wherein the intake manifold is removed. FIGS. 5 to 8 show a sub-Intake manifold.

[0026] A dual-injector fuel injection engine 1 according to this embodiment is a V-type 6-cylinder engine to be mounted in an automobile, and comprises a first cylinder row 2 located on the left side in FIG. 1 and a second cylinder row 3 located on the right side in FIG. 1. The cylinder rows 2 and 3 have the same arrangement, and accordingly the first cylinder row 2 will be described in detail. The respective members of the second cylinder row 3 are denoted by the same reference numerals as in the first cylinder row 2, and a description thereof will be omitted....

second embodiment

[0081] An intake manifold can be formed as shown in FIG. 9 or 10.

[0082]FIGS. 9 and 10 show other embodiments. In FIGS. 9 and 10, the same or equivalent members as those described with reference to FIGS. 1 to 8 are denoted by the same reference numerals, and a detailed description thereof will be omitted as needed.

[0083] An intake manifold 21 shown in each of FIGS. 9 and 10 comprises a main intake manifold 91 having a structure different from that of the first embodiment, and is provided with surge tanks 92 and 93 for the respective cylinder rows. This will be described in detail. Of the main intake manifold 91 shown in FIG. 9, the surge tank 92 communicating with the intake passage of a first cylinder row 2 is located above a second cylinder row 3, and the surge tank 93 communicating with the intake passage of the second cylinder row 3 is located above the first cylinder row 2.

[0084] In the main intake manifold 91 shown in FIG. 10, the surge tank 92 communicating with the intake ...

third embodiment

[0087] The present invention can also be applied to a multi-cylinder engine having only one cylinder row, as shown in FIG. 11.

[0088]FIG. 11 shows still another embodiment. In FIG. 11, the same or equivalent members as those described with reference to FIGS. 1 to 10 are denoted by the same reference numerals, and a detailed description thereof will be omitted as needed.

[0089] A dual-injector fuel injection engine 95 shown in FIG. 11 is an in-line multi-cylinder engine having only one cylinder row. This engine 95 has almost the same structure as that of the V-type multi-cylinder engine 1 shown in FIGS. 1 to 8 except that the number of cylinder rows is different. Thus, a sub-intake manifold 51 of an intake manifold 21 employed in the dual-injector fuel injection engine 95 of this embodiment is formed of only one side of the sub-intake manifold 51 shown in the first embodiment so as to be connected to intake ports 11 of one cylinder row. A main intake manifold 52 has a pipe-shaped por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com