Textile component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

I. First Embodiment

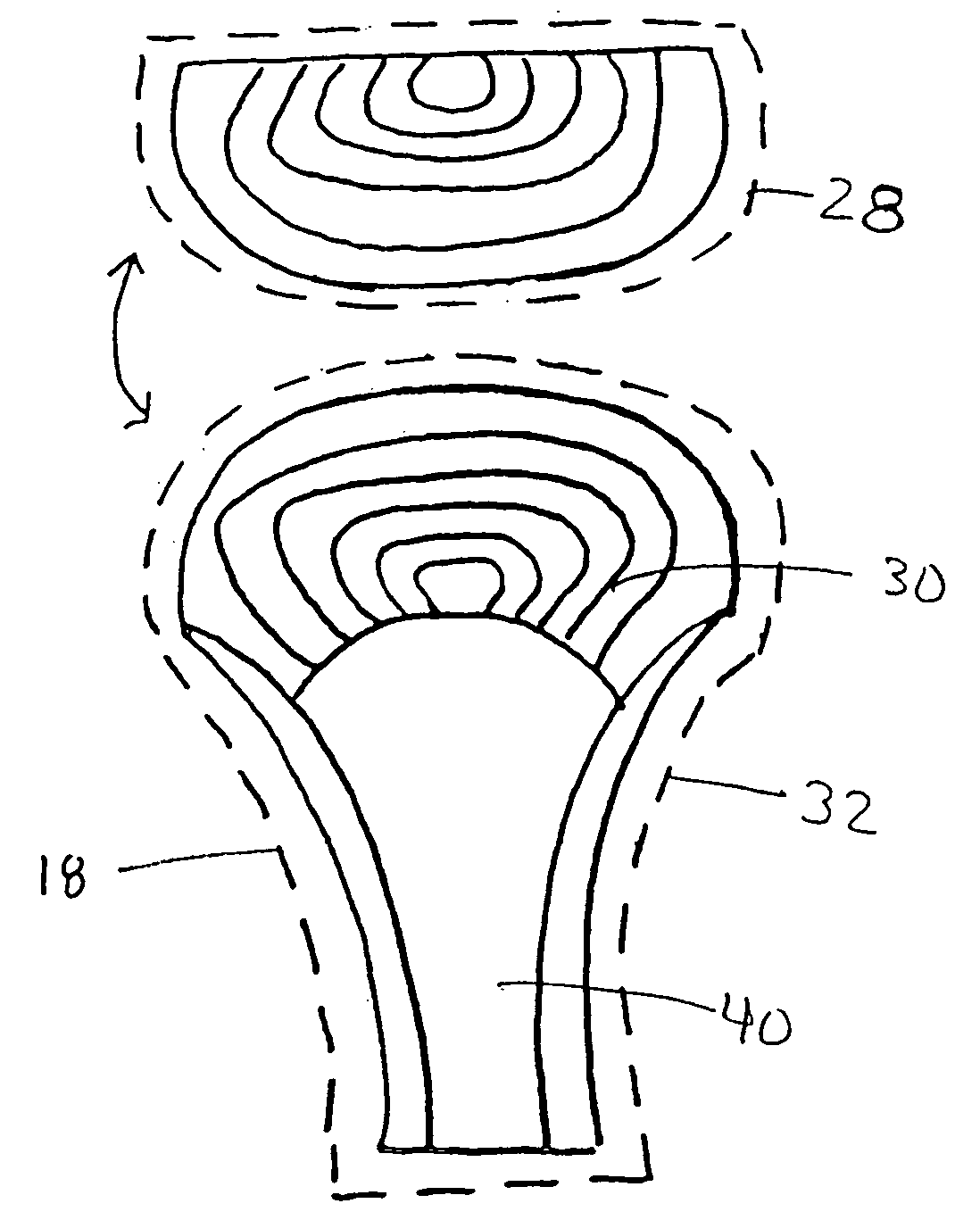

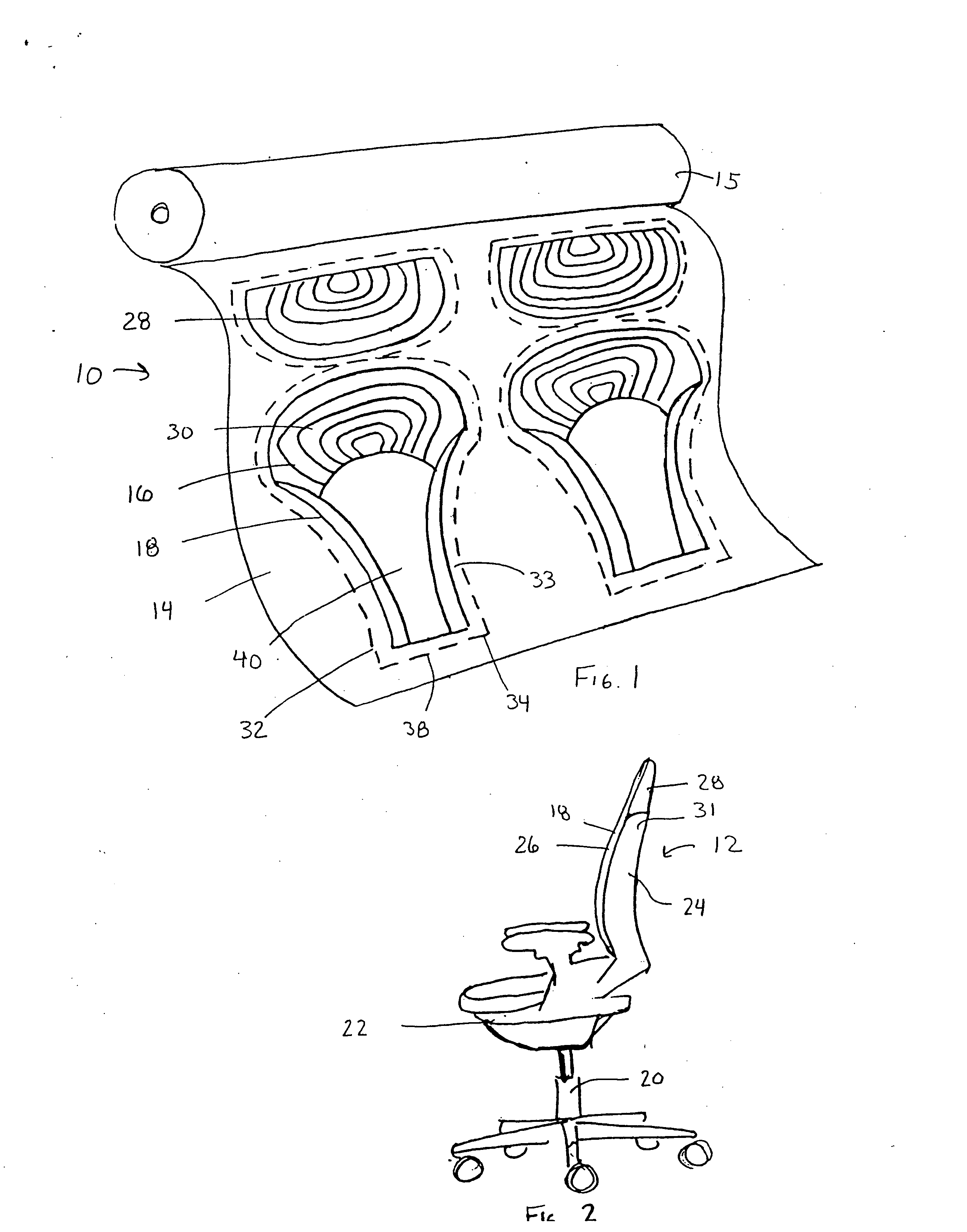

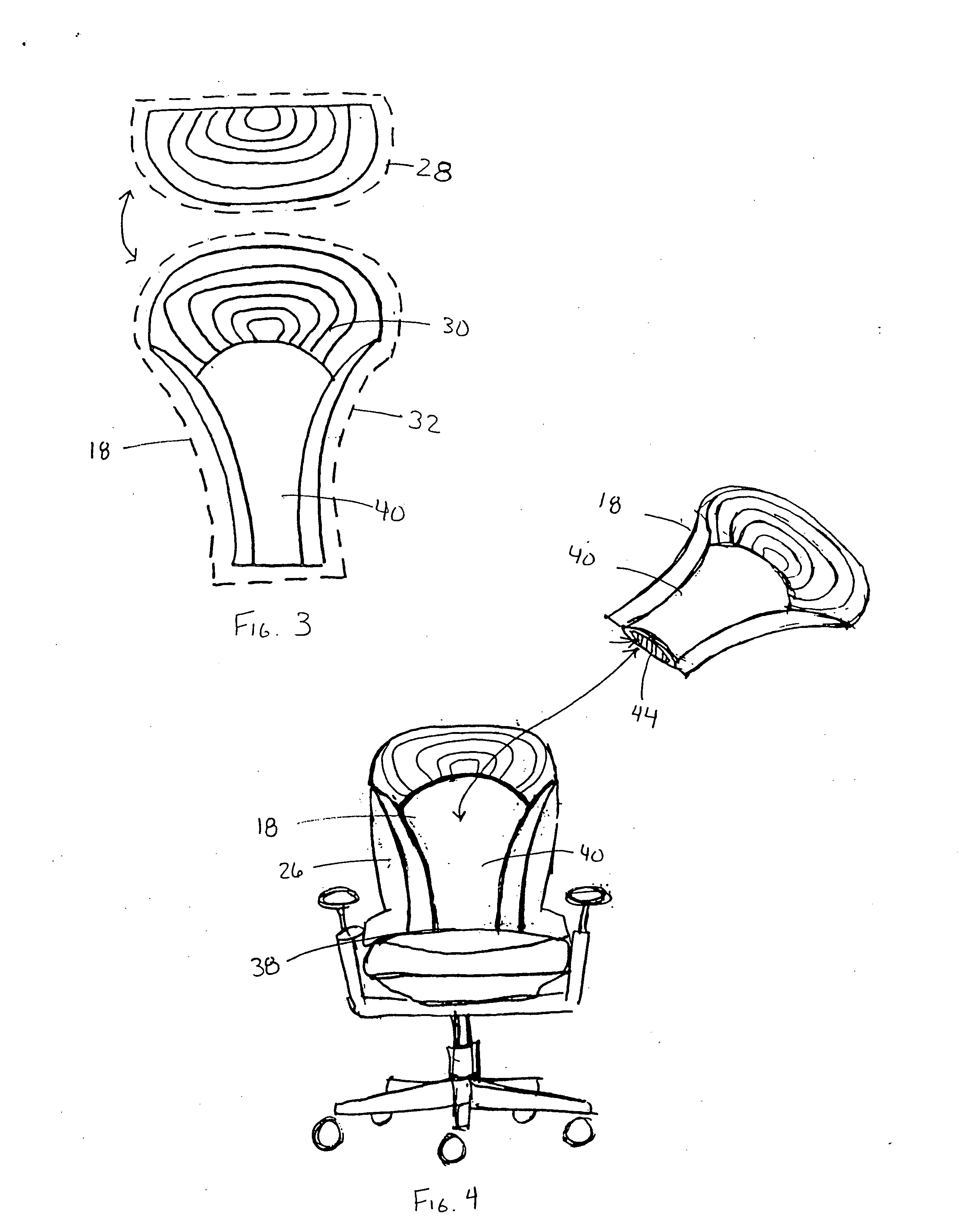

[0077] A textile component in accordance with a first embodiment of the present invention is shown in FIG. 1, and generally designated 10. In this embodiment, the textile component is shown in connection with an office chair 12. For illustrative purposes, the component 10 will be described in connection with the particular office chair 12 shown, however, the component 10 is adaptable for use with many different applications, including a variety of seating applications, such as, pedestal chairs, residential, automotive and transportation seating. Shown in FIG. 2, the chair 12 generally includes a base 20, a seat component 22, and a back support component 24.

[0078] As shown in FIG. 1, the textile component 10 is generally woven into a web of fabric 14. The web 14 may be formed into a variety of widths and lengths, and formed out of a variety of fibers and yarns set at a variety of end counts (number of yarns per inch in the warp) and pick counts, (number of yarns p...

second embodiment

II. Second Embodiment

[0090]FIGS. 40-50 show a second embodiment of the present invention, wherein the textile component is attached to a privacy screen. As shown in FIG. 40, the textile 100 is formed by the jacquard method into a web 102 and disposed on a roll 104 similar to that described in the first embodiment. In this case, the web 102 includes a series of repeating (or non-repeating) patterns 106, that can be divided into panels 120. The patterns 106 may each include a desired design 108, and a periphery 110. The peripheries 110 of each sequential pattern may be separated by a cut line 112. The cut line 112 is similar to the cut lines 34, 64 described in connection with the first embodiment in that it is typically a binding weave that defines the periphery 110 of the pattern and is distinguishable from the rest of the web 102 and the design 108. After the web 102 is formed, the individual panels 120, shown in FIG. 44, may be separated by cutting along the cut line 112 with a co...

third embodiment

III. Third Embodiment

[0093] A third embodiment of the present invention is shown in FIGS. 51-52 and FIGS. 54-56. In this embodiment, the textile component 200 is shown attached to a lampshade base 202. As shown in FIG. 56, the lamp shade base 202 includes a weight 204, a stem 206, four cross members 208 arranged in approximately a square, a pair of vertical support beams 210 extending from each corner of the cross members 208. In order to attach the textile component 200 to the base 202, four panels 212 are positioned in a square, with a pair of channels 214 extending over each pair of beams 210. As shown in FIG. 51, the textile component 200 is formed on a roll 216 similar to the first two embodiments. In this case, the fabric 200 includes cut lines 218 every fourth panel 212 to form a web 215 (shown in FIG. 54) of sequential panels that will remain connected for attachment to the base 202. Shown in FIG. 54, the cut lines 218 define a margin 220 at the periphery of each web 215. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com