Method of depositing an anti-wear coating by thermal spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

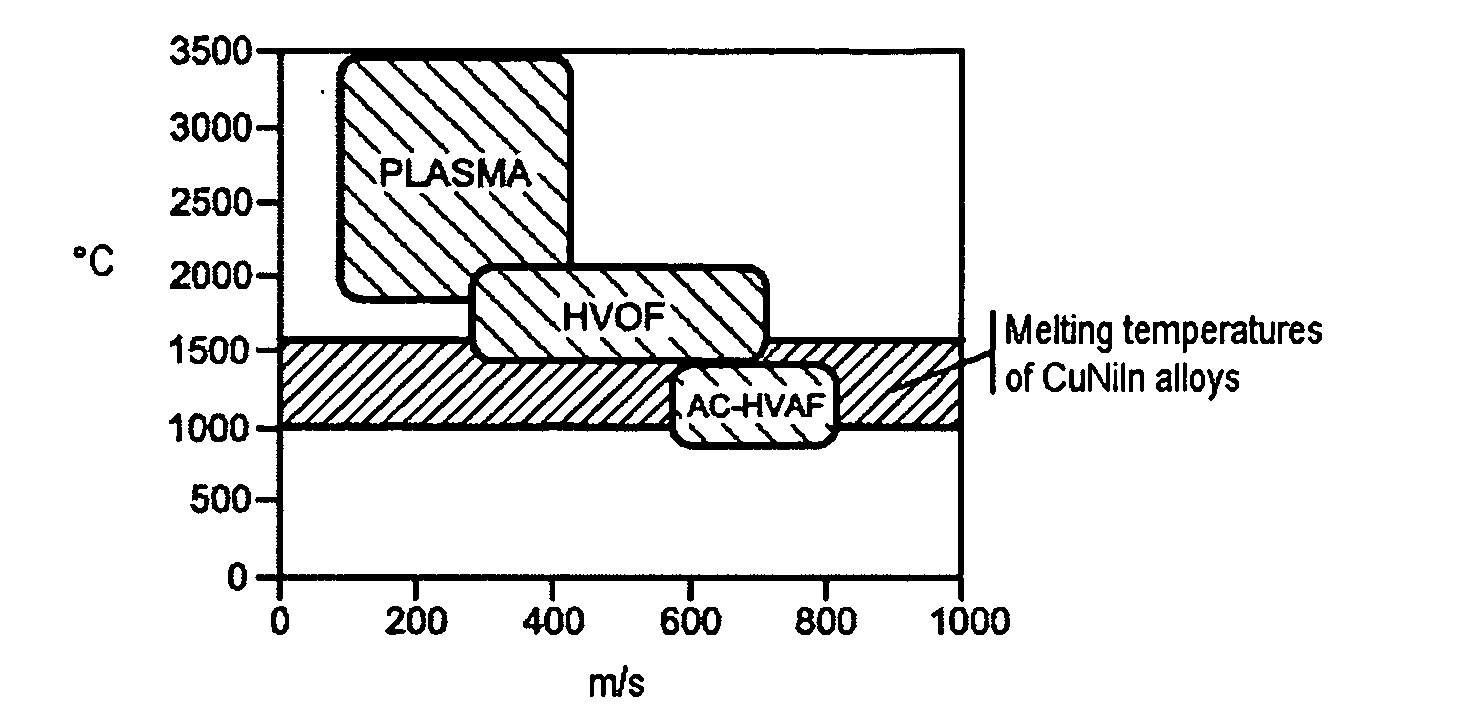

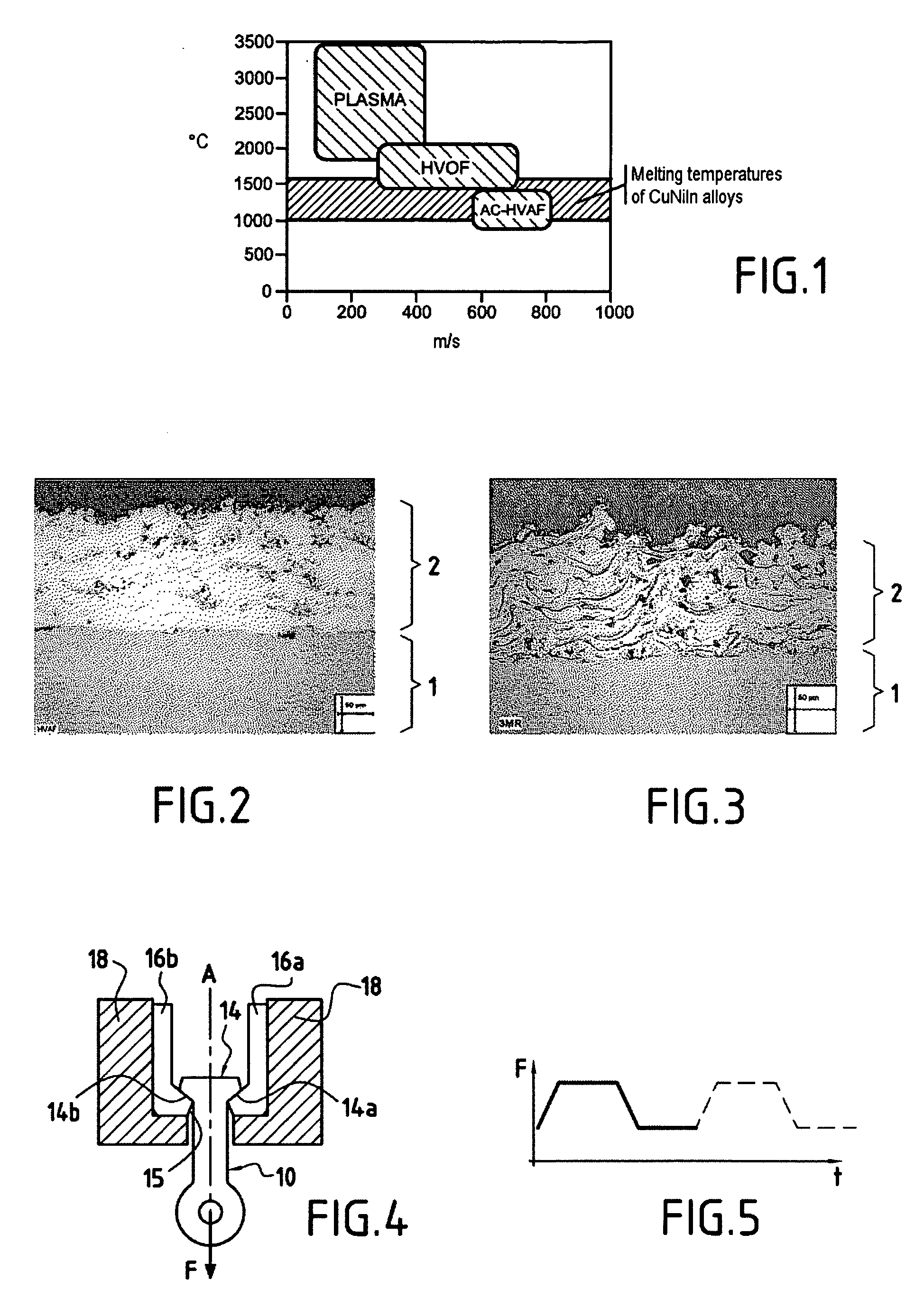

[0029] The plot of FIG. 1 has spray speed in m / s plotted along the abscissa and spray temperature in ° C. plotted up the ordinate, as obtained when using various thermal spraying methods. In this plot, there can be seen outlines for temperature and spray speed ranges for plasma, HVAF, and AC-HVAF spraying. Furthermore, the range of temperatures over which a copper-based alloy such as the CuNiIn alloy melts is also shown.

[0030] In this diagram, and as described above, it can be seen that the temperatures reached in AC-HVAF spraying are adapted to the melting range of the CuNiIn alloy used in the invention, thus making it possible to melt these alloys without useless overheating that would encourage oxidation. Furthermore, it can also be seen that higher spraying speeds can be obtained by using AC-HVAF spraying.

[0031] An implementation of the method of the invention is described below by way of example, in which a CuNiIn alloy was deposited on a part made of a titanium alloy of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com