Hydraulic fracturing

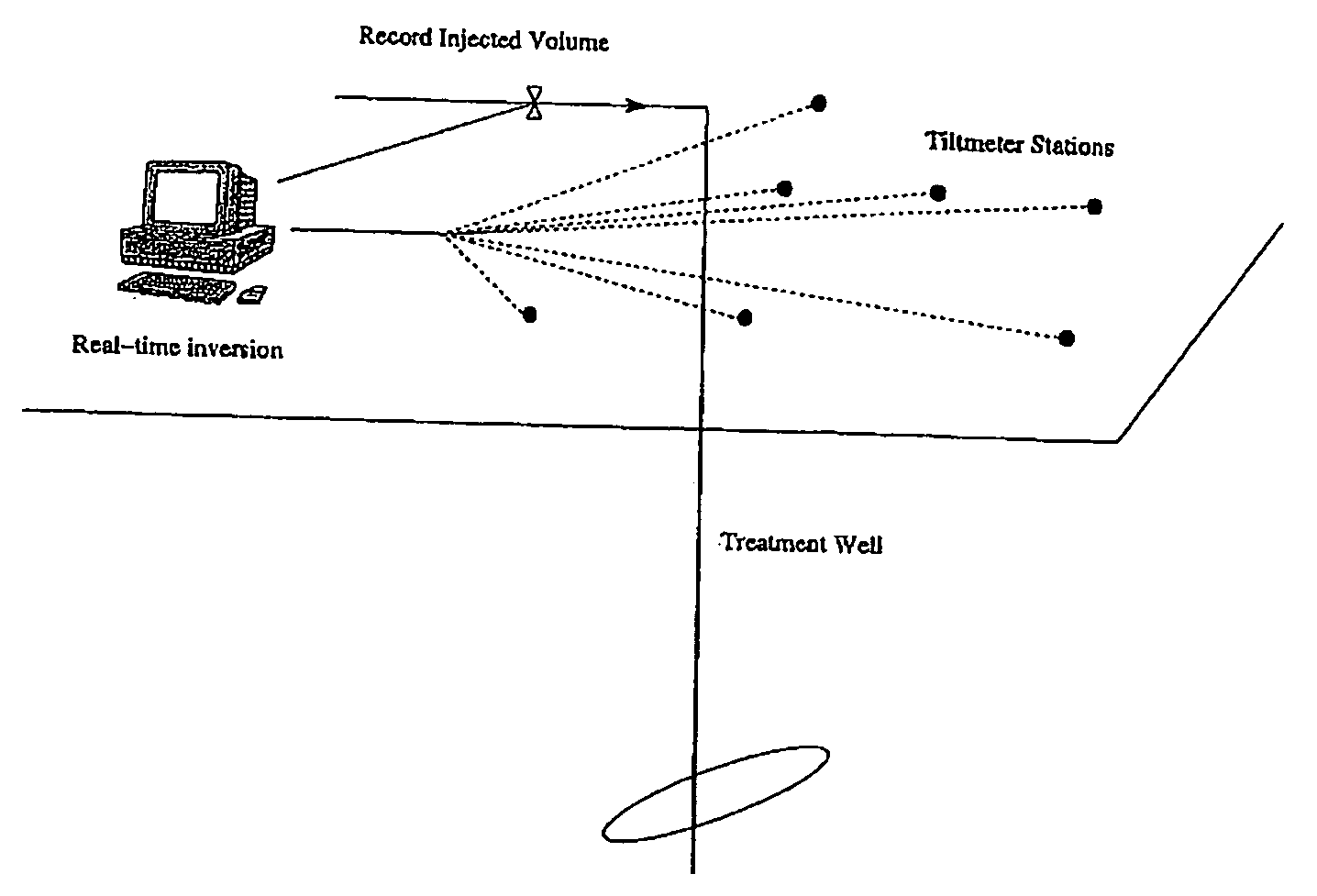

a technology of hydraulic fracturing and fracturing chamber, which is applied in the field of hydraulic fracturing, can solve the problems of inability to produce accurate real time information, limited direct measurement capability of operators,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

an example

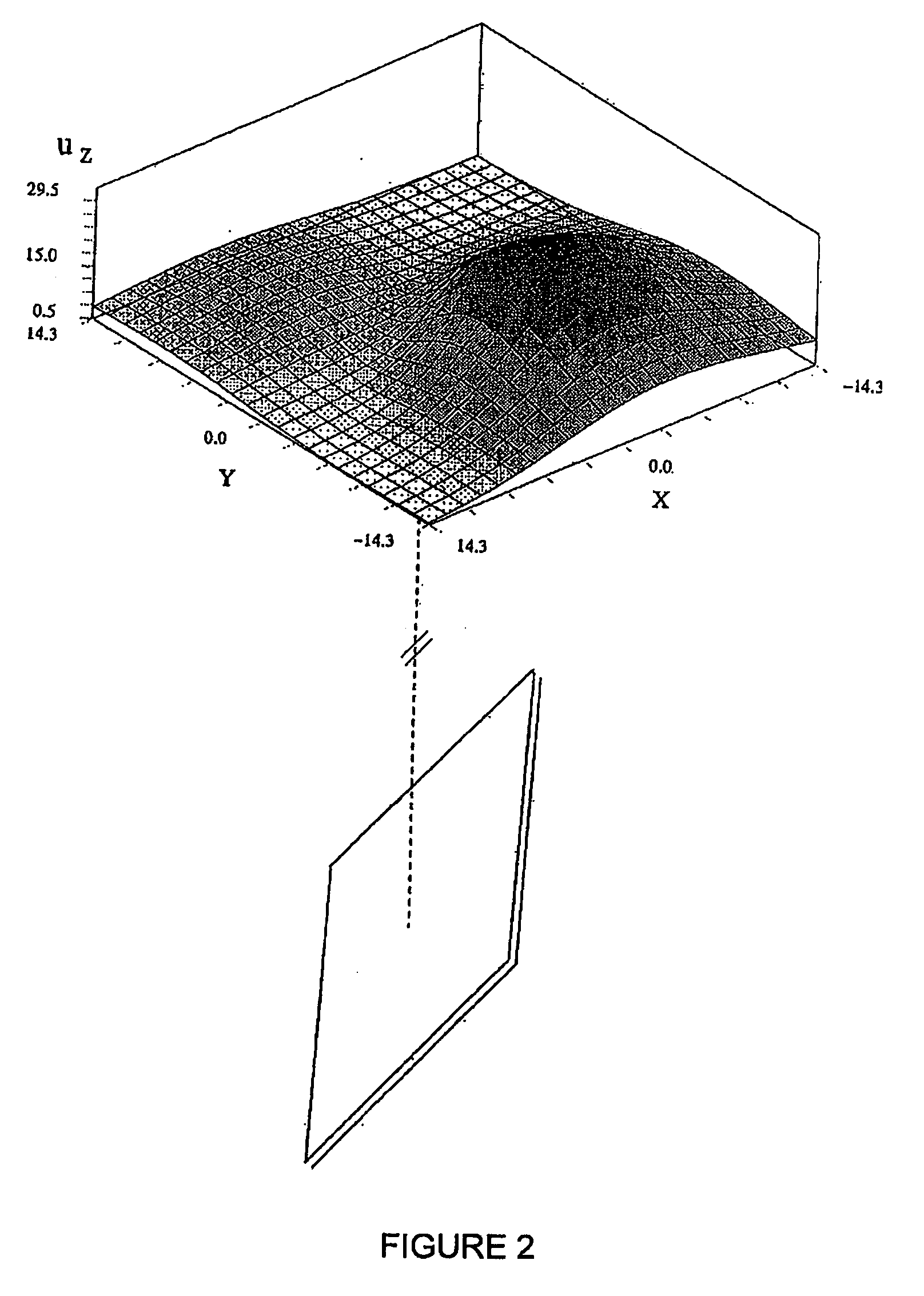

[0060] As an illustrating example, let consider the following synthetic case. The tiltmeter data corresponding to the growth of a Hydraulic Fracture of so-called PKN geometry (with coefficients α=2, β=2e−3, see eqns (1)-(2)) . . . are simulated and noise is added to this synthetic data set. The data are logged by a borehole array located 200 meters from the fracture (a far-field array). Tilts are sampled every minute. The synthetic data are then inverted using the same PKN model for the fracture growth model (see eqns. (1)-(2)). The parameters (α,β) are supposed unknowns and are retrieved via an inverse calculation using the simulated tilt data. The values of both parameters are retrieved accurately, we obtain α=1.94, β=1.98e−3. The fit of the tilt data at a particular tilt station can be seen in FIG. 6. FIG. 5 shows the time evolution fracture half-length and aperture at the fracture center obtained from eq. and the estimated values of the coefficients α and β. The estimated values...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com