Ink sheet cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

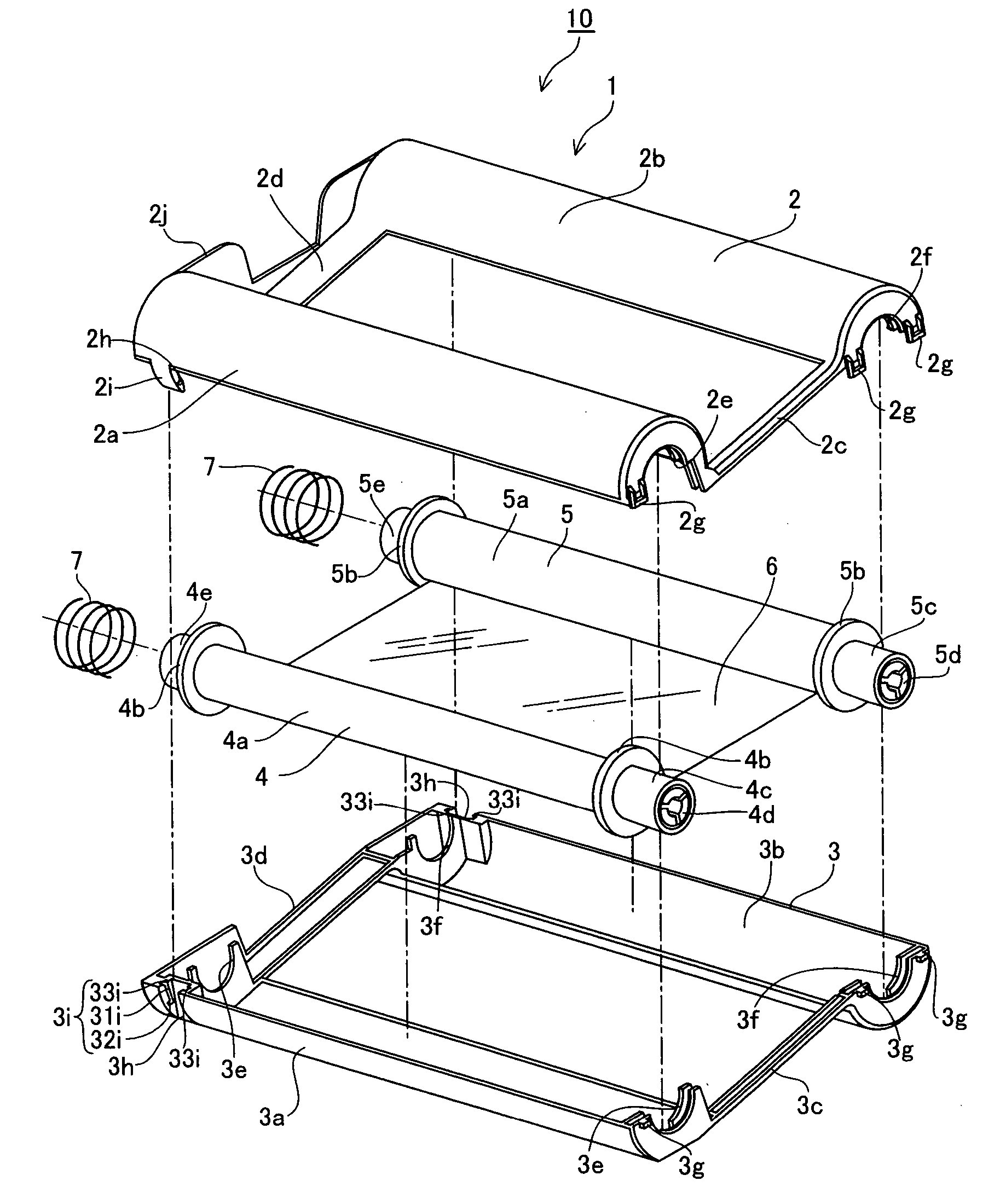

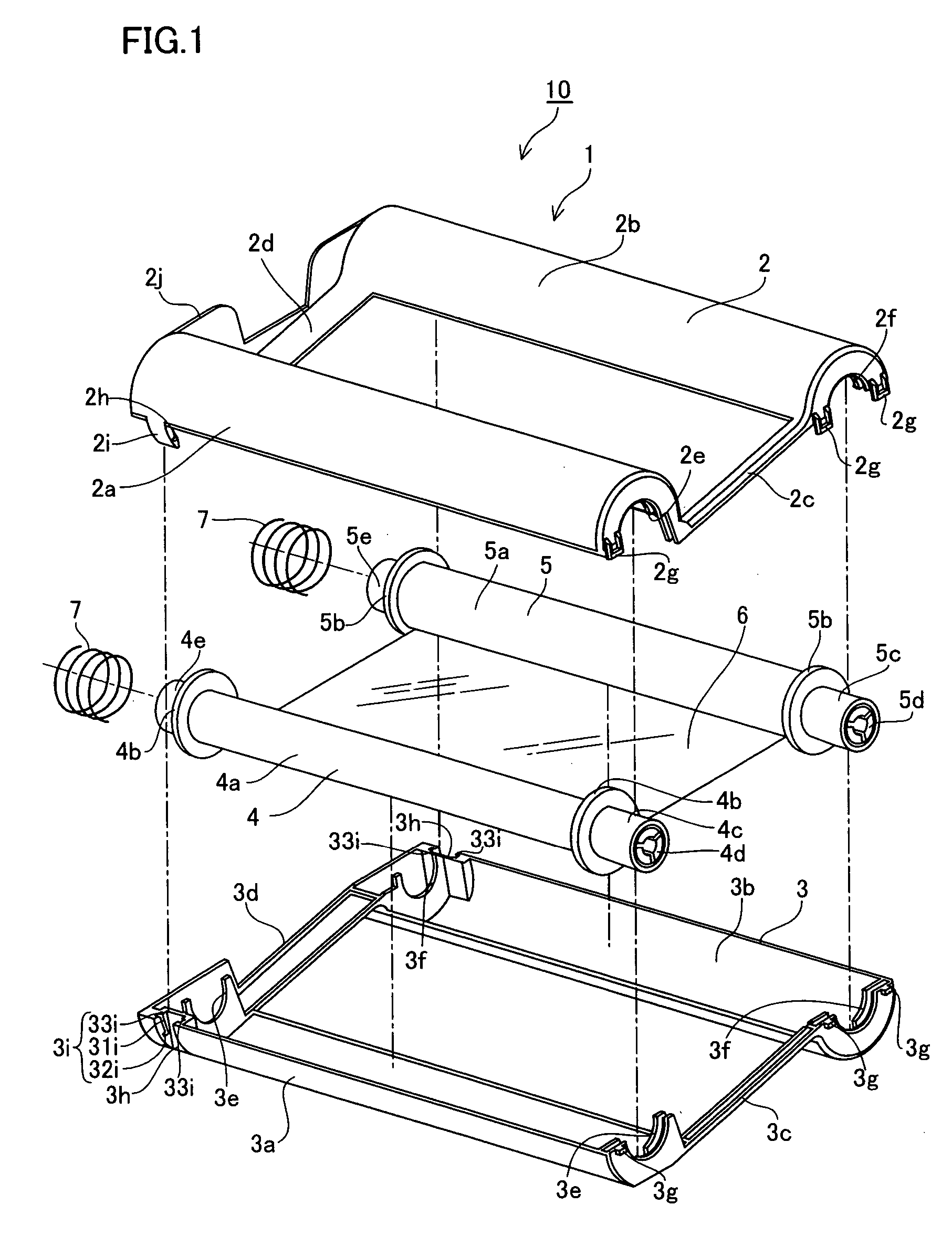

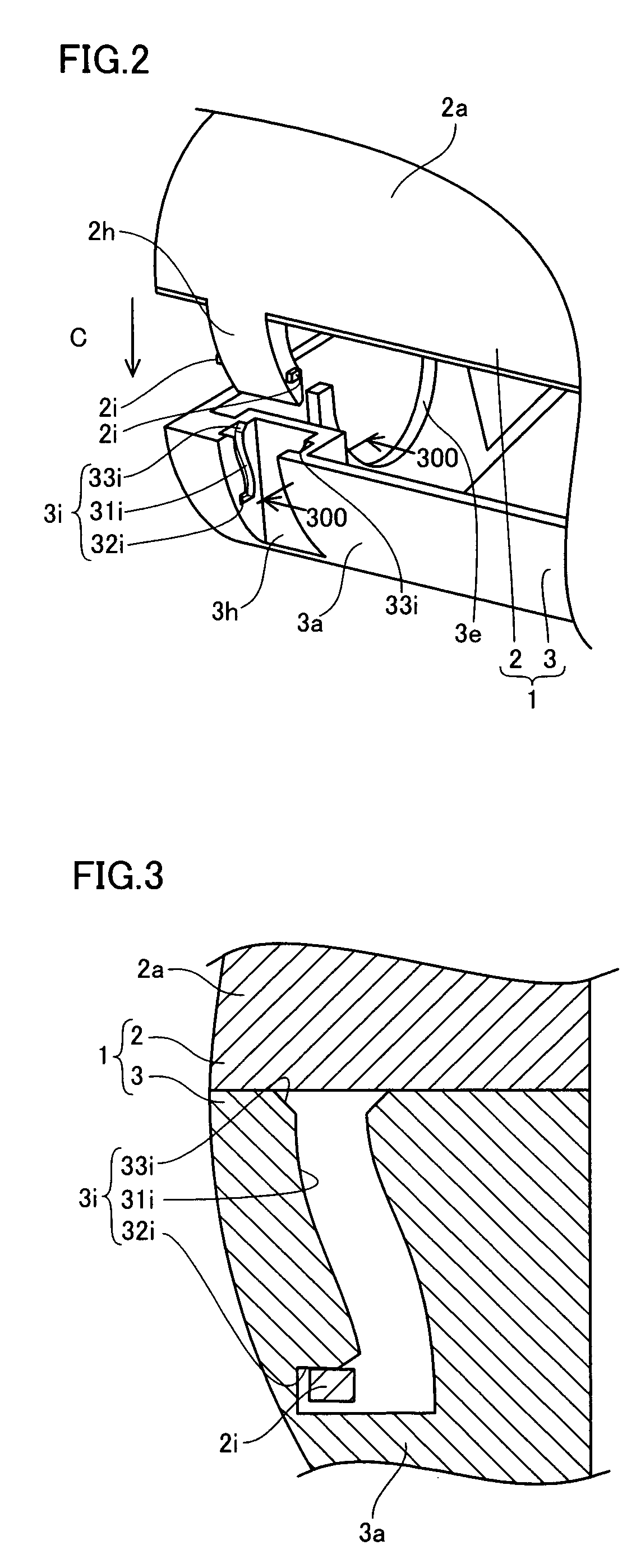

[0058] An embodiment of the present invention is now described with reference to the drawings.

[0059] First, the structure of an ink sheet cartridge 10 according to the embodiment of the present invention is described with reference to FIGS. 1 to 15.

[0060] As shown in FIG. 1, the ink sheet cartridge 10 according to the embodiment of the present invention comprises a resin upper component 2 and a resin lower component 3 constituting a bobbin case 1, a feed bobbin 4 feeding an ink sheet 6, a take-up bobbin 5 taking up the ink sheet 6, the ink sheet 6 and a compression coil spring 7 for urging the feed bobbin 4 and the take-up bobbin 5 toward an end of the bobbin case 1.

[0061] The upper component 2 constituting the bobbin case 1 includes a feed bobbin storage portion 2a storing the feed bobbin 4, a take-up bobbin storage portion 2b storing the take-up bobbin 5 and coupling portions 2c and 2d coupling the feed bobbin storage portion 2a and the take-up bobbin storage portion 2b with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com