Dual capacity sink

a double-capacity, sink technology, applied in the direction of washstands, water installations, constructions, etc., can solve the problems of insufficiently addressing long-standing problems, dividing the overall size of the sink, so as to facilitate the transfer of items, increase the capacity of washing, and increase the clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

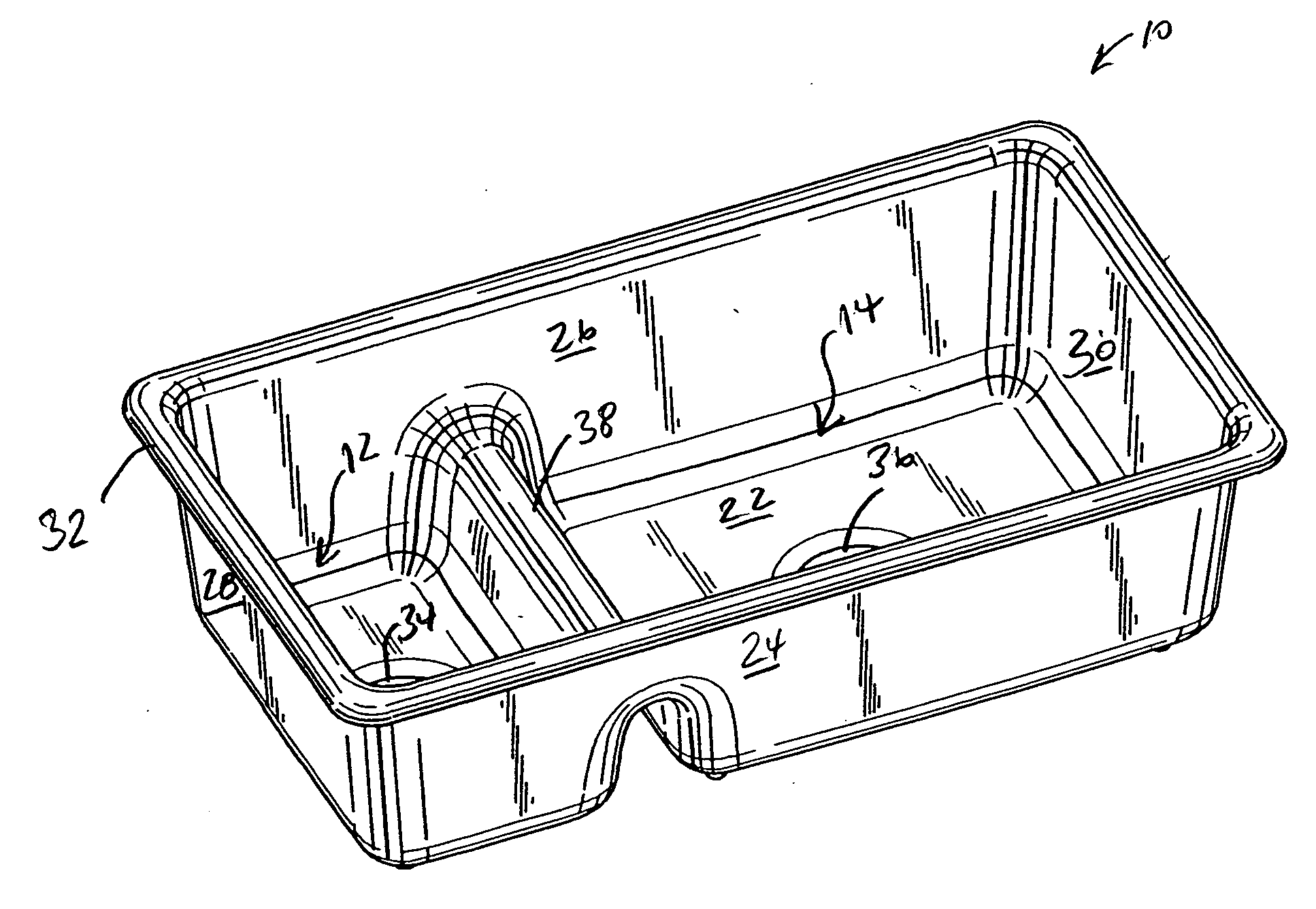

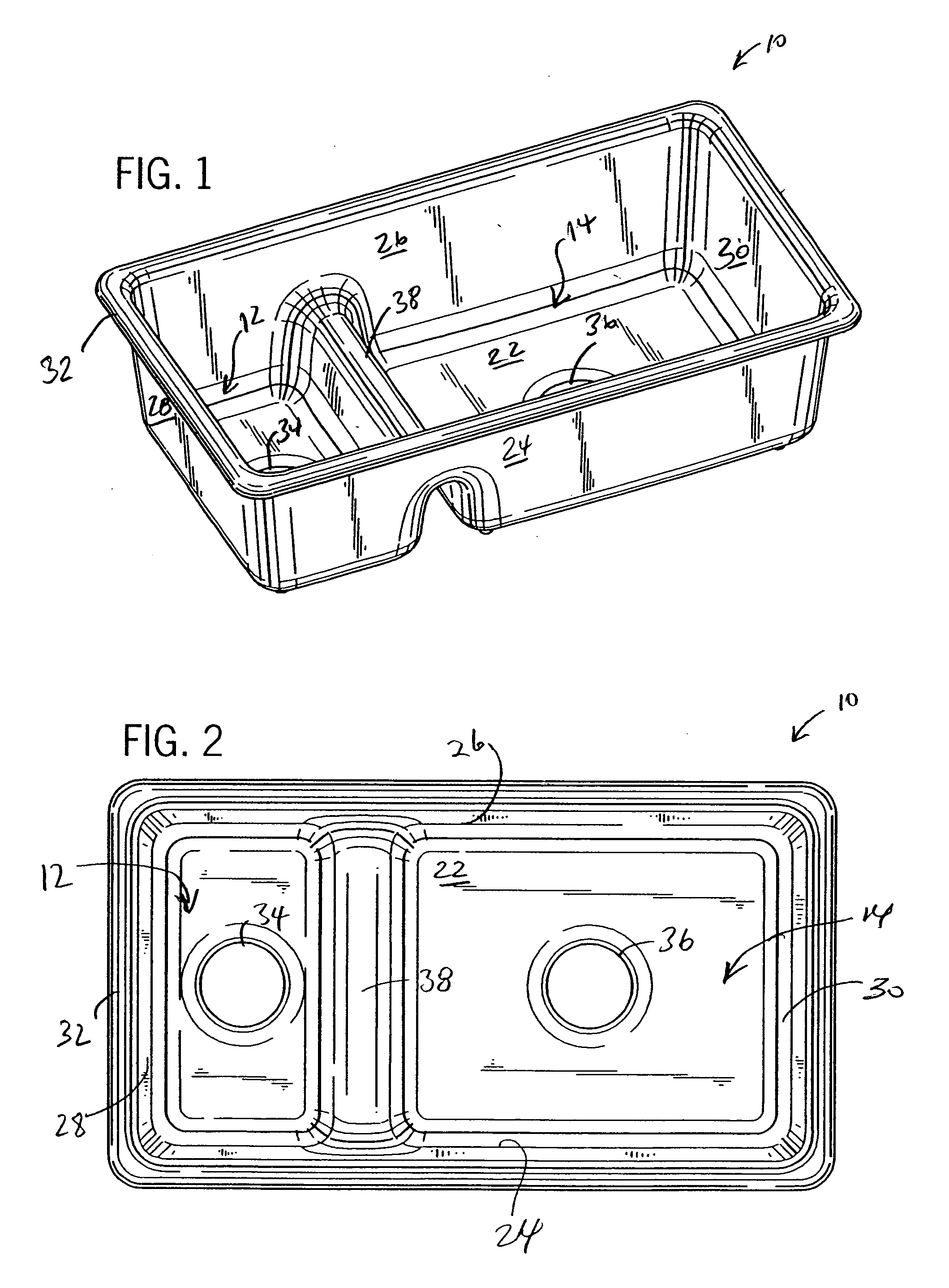

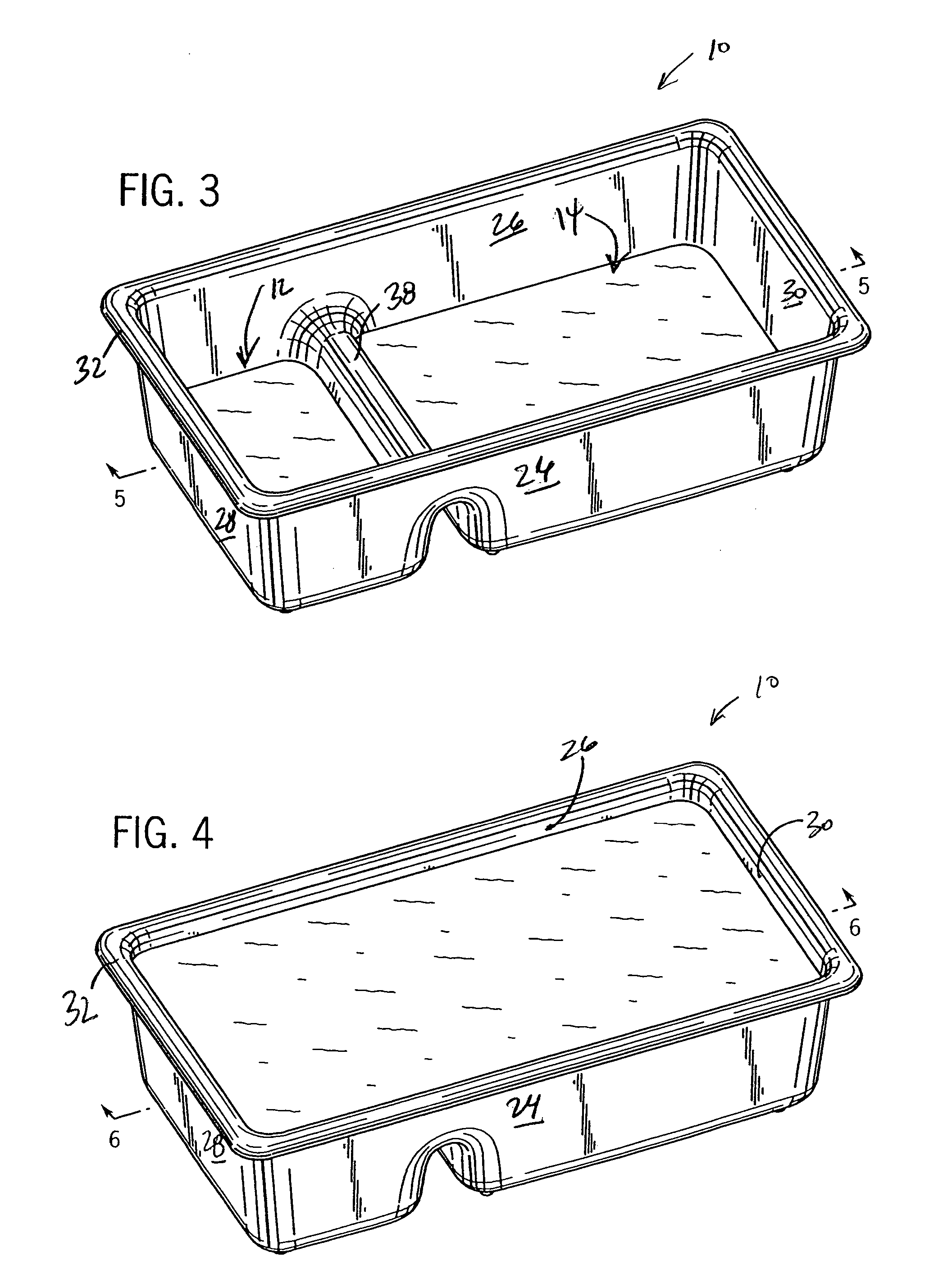

[0027]FIGS. 1-6 illustrate a first dual capacity sink 10 having unequally sized basins 12 and 14, and FIGS. 7-11 illustrate an alternate sink 10A in which the basins 12A and 14A are the same other than being mirror images. The embodiment shown in FIGS. 7-11 can be readily understood from a description of the FIGS. 1-6 embodiment in that it is generally the same but for the equal sized basins and the addition of a back deck 16, which can be used to mount a faucet 18 (such as shown in FIGS. 5, 6, 10 and 11) which can spray water directly into each of the basins. Given the similarity of the two sinks 10 and 10A, the following description will be directed only to the sink 10 shown in FIGS. 1-6.

[0028] The sink 10 can be made of cast iron or other materials, and referring to FIGS. 1 and 2, it has the larger, primary basin 14 and the smaller basin 12. The sink has a bottom 22 and front 24, rear 26, left 28, and right 30 upright side walls with a turned rim 32 extending along the upper per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com