Longitudinal support

a technology of longitudinal support and supporting elements, applied in the direction of internal osteosynthesis, osteosynthesis devices, constructions, etc., can solve the problems of biocompatibility and high elasticity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

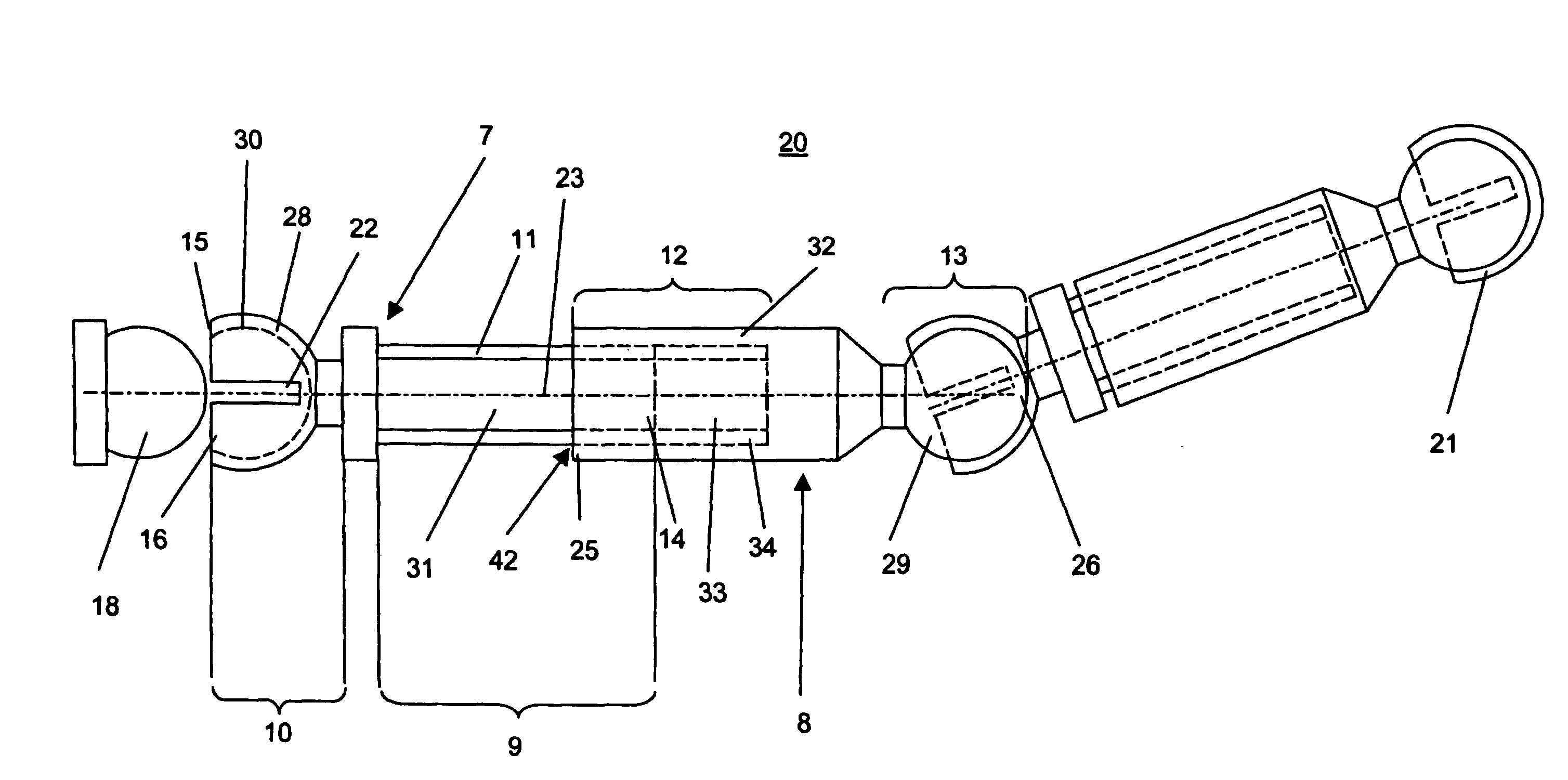

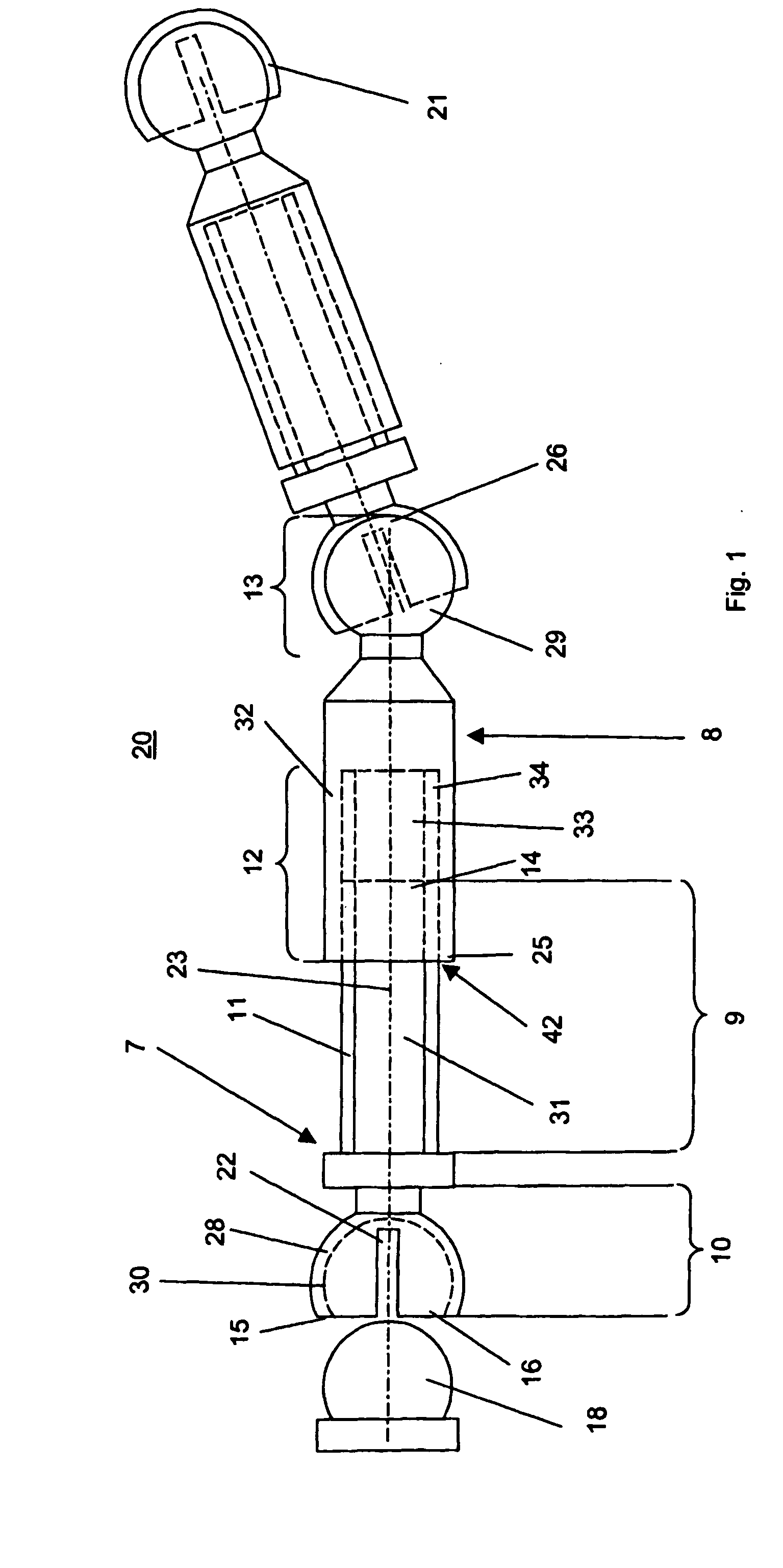

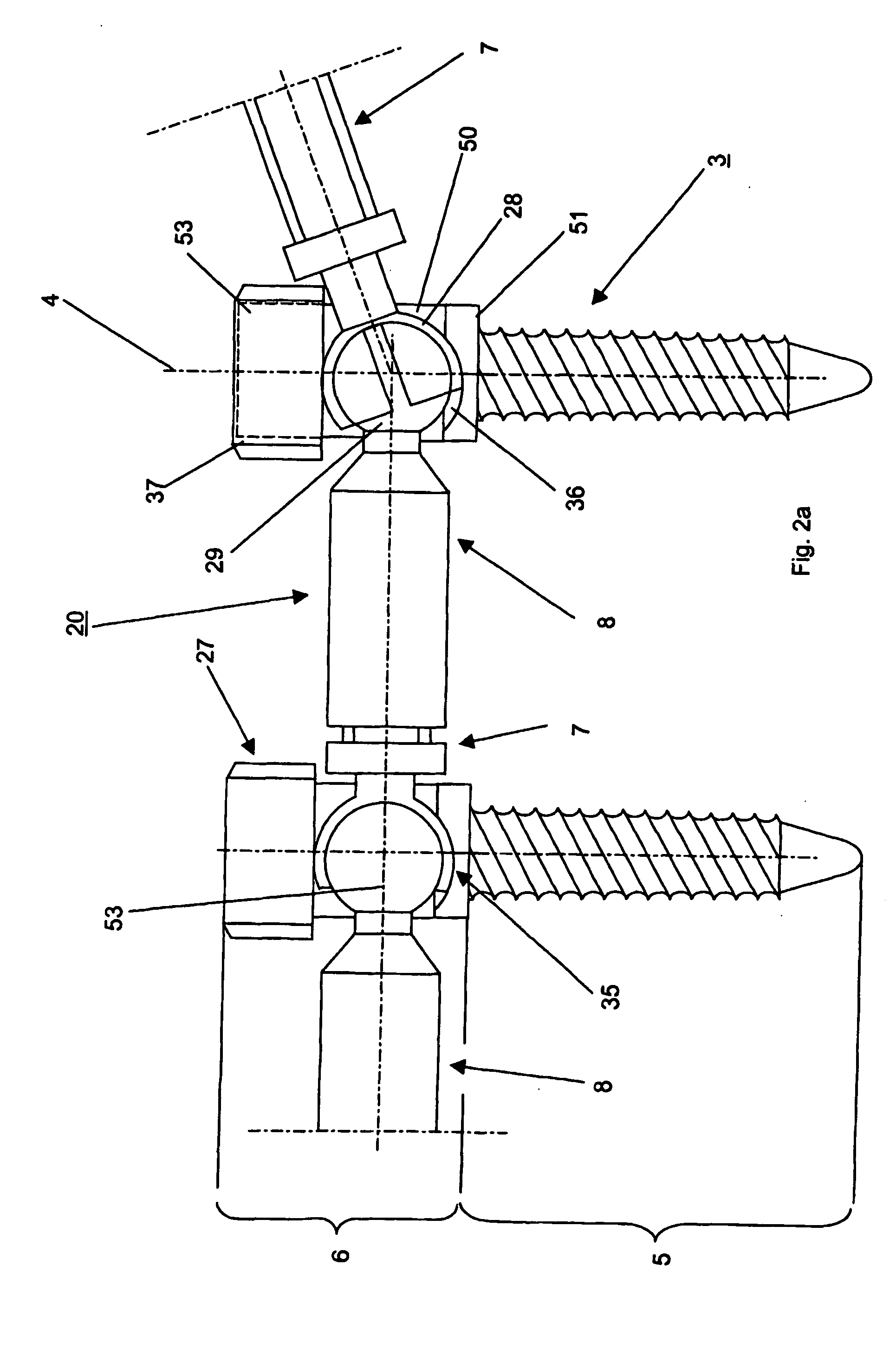

[0024]FIG. 1 illustrates an embodiment of the longitudinal support 20. The longitudinal support 20 has type A longitudinal support elements 7, type B longitudinal support elements 8, and end-pieces 18 and 21.

[0025] Type A longitudinal support element 7 includes first connecting segment 9 and second connecting segment 10 which are coaxial with a first longitudinal axis 23 of the longitudinal support element 7. The longitudinal support element 7 has a first end 14 and a second end 15. The second end 15 is located next to the second connecting segment 10. The first connecting element 9 of the longitudinal support element 7 (type A) is constructed as a cylindrical shaft 31 with a thread 11. The second connecting segment 10 of longitudinal support element 7 (type A) comprises an articulated socket 28 with a hollow spherical segment-like, coaxial cavity 30. The socket 28 can be elastically deformed transversely to the first longitudinal axis 23, while the cavity 30 at the second end 15 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com