Fiber optic connector having keyed ferrule holder

a fiber optic connector and ferrule holder technology, applied in the field of fiber optic connectors, can solve the problems of reducing signal transmission, unable to polish the two ferrule end faces in the same plane using conventional apparatus and processes, and the design of the hardened connector does not allow the separation of ferrules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

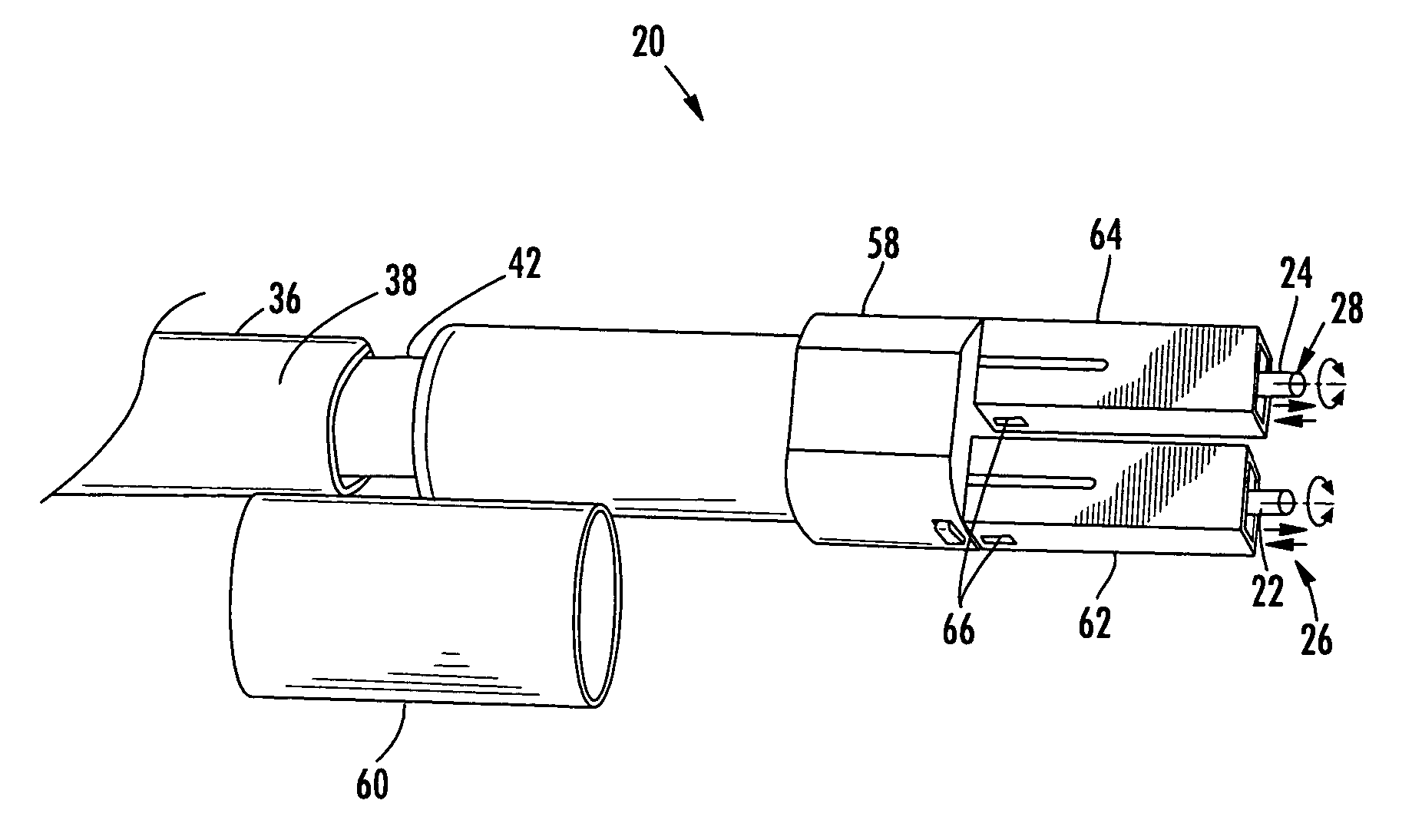

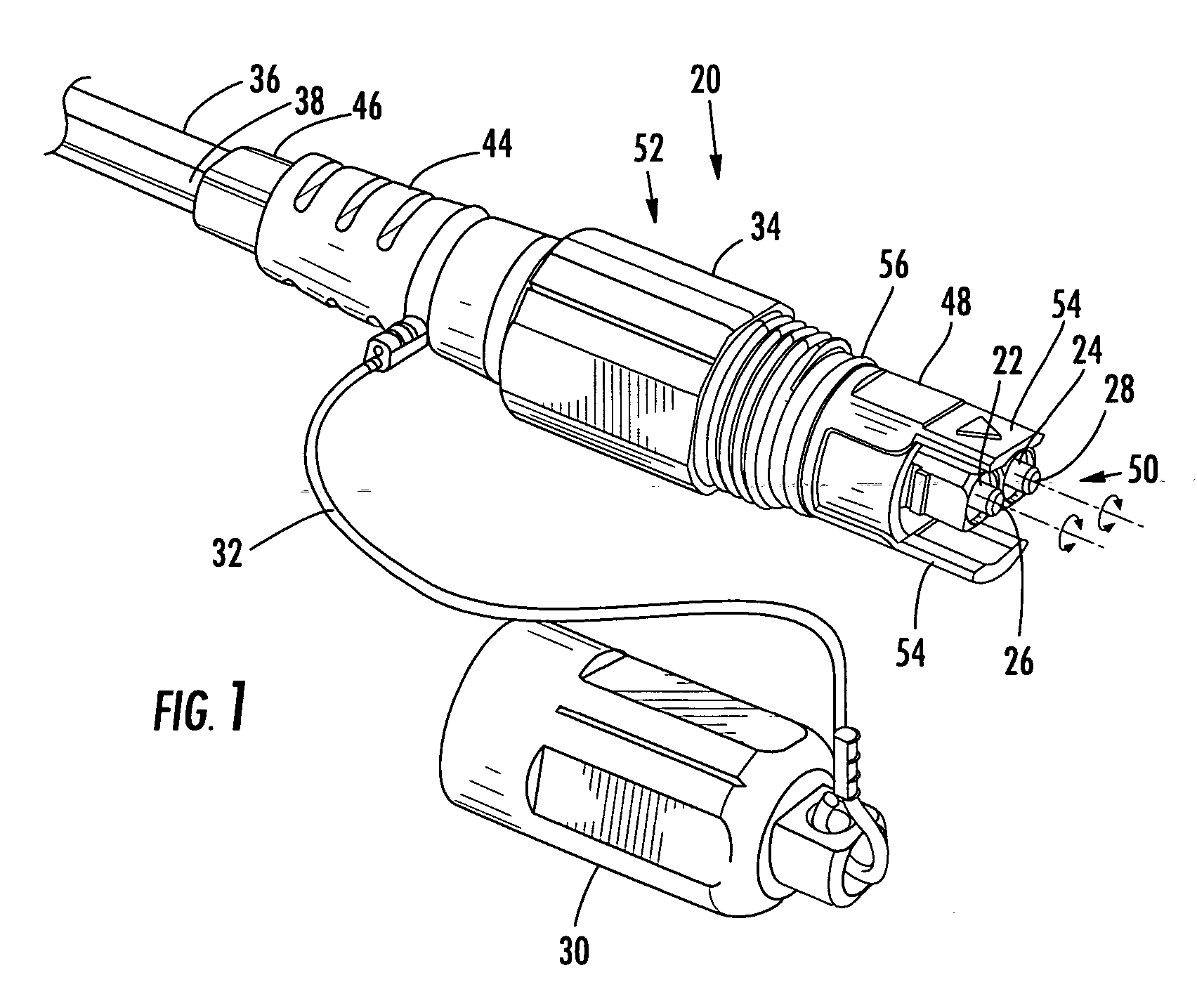

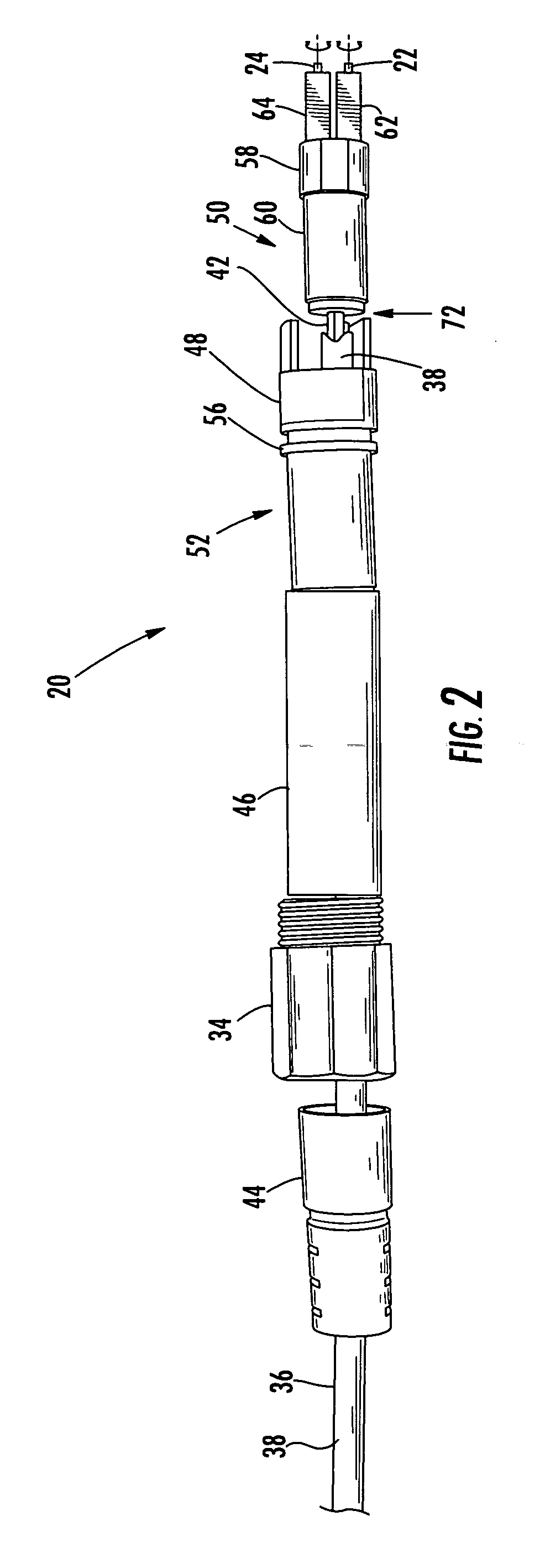

[0023] Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Whenever possible, the same reference numerals will be used throughout the drawings to refer to the same or like parts. An exemplary embodiment of a duplex fiber optic connector according to the invention is shown in FIG. 1 with the fiber optic connector designated generally throughout the various figures by reference numeral 20.

[0024] Referring now specifically to the accompanying drawings, FIGS. 1-6 show a duplex fiber optic connector 20 including two individual SC APC connectors mounted side-by-side on a duplex cable. As is known in the art, SC connectors include a single optical fiber in a standard-sized (2.5 mm diameter) ceramic ferrule. As is also known in the art, LC connectors hold a single optical fiber in a smaller (1.25 mm diameter) ceramic ferrule and may be used in environments in which a small form factor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com