Pressure-assisted toilet flush cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

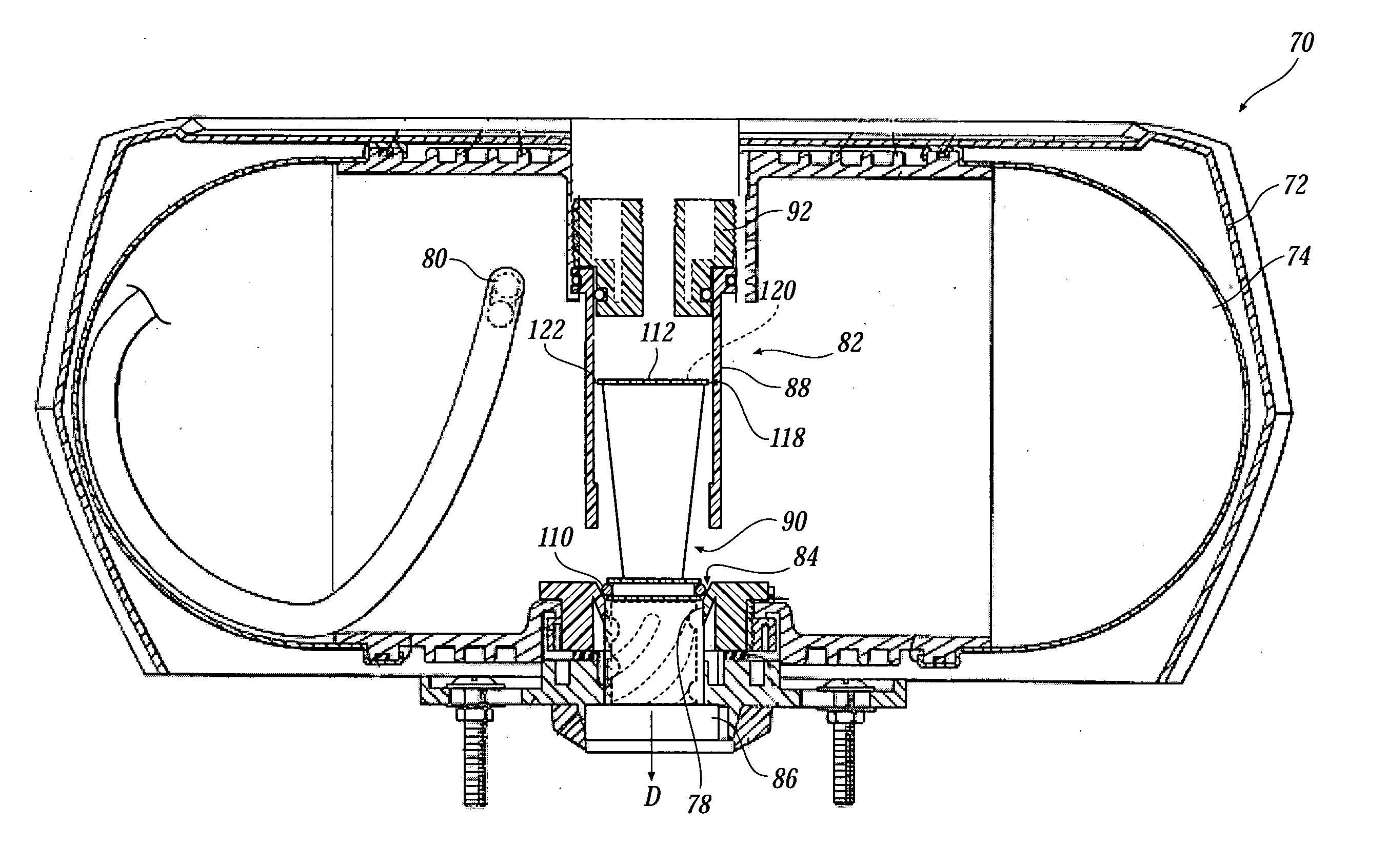

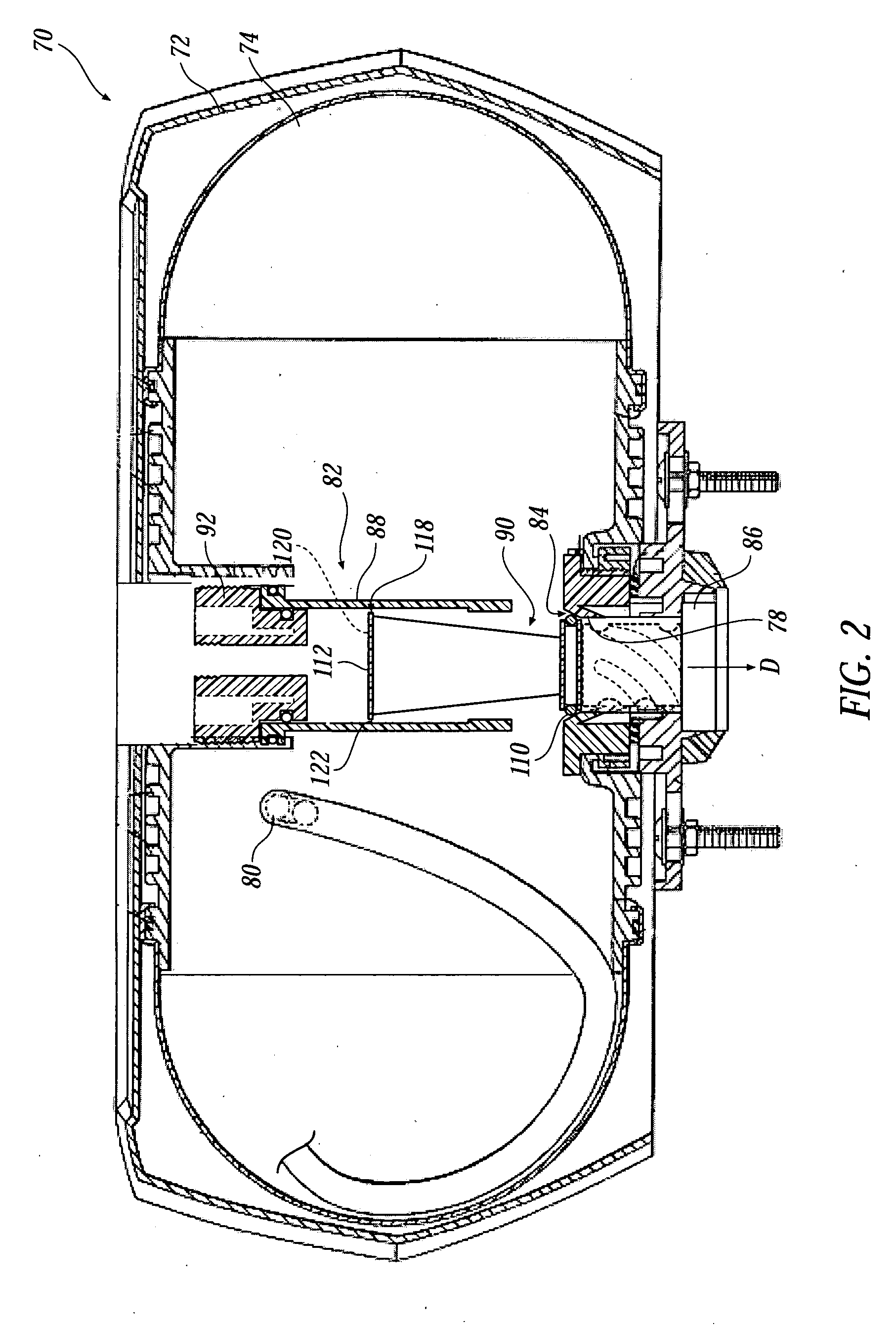

[0018]FIG. 2 illustrates a pressure assisted toilet flush system 70 in accordance with an embodiment of the present invention. The system 70 includes a vessel, or pressure tank, 74 having a discharge outlet 78 and an inlet 80, and a flush cartridge 82. Discharge outlet 78 is preferably defined in part by a frusto-conical interior surface 84 and a generally cylindrical surface 86, as discussed below.

[0019] With reference to FIGS. 2 and 3, flush cartridge 82 includes a jacket, or outer housing, 88, a flush valve 90, and a top cap 92. Outer housing 88 includes a cylindrical body (or jacket) 94 that extends from a top end 96 to a bottom end 98, and an internal surface 100. Top end 96 defines a larger inside diameter than bottom end 98, and internal surface 100 is accordingly tapered from top end 96 to bottom end 98. Internal surface 100 includes a retaining element 104 disposed thereon and extending inwardly from the internal surface 100. Preferably, retaining element 104 is three equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com