Reinforcement ring

a technology of reinforcement rings and rings, applied in the field of reinforcement rings, can solve the problems of elements liable to deform under high pressure, and achieve the effect of preventing deformation or twisting of rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

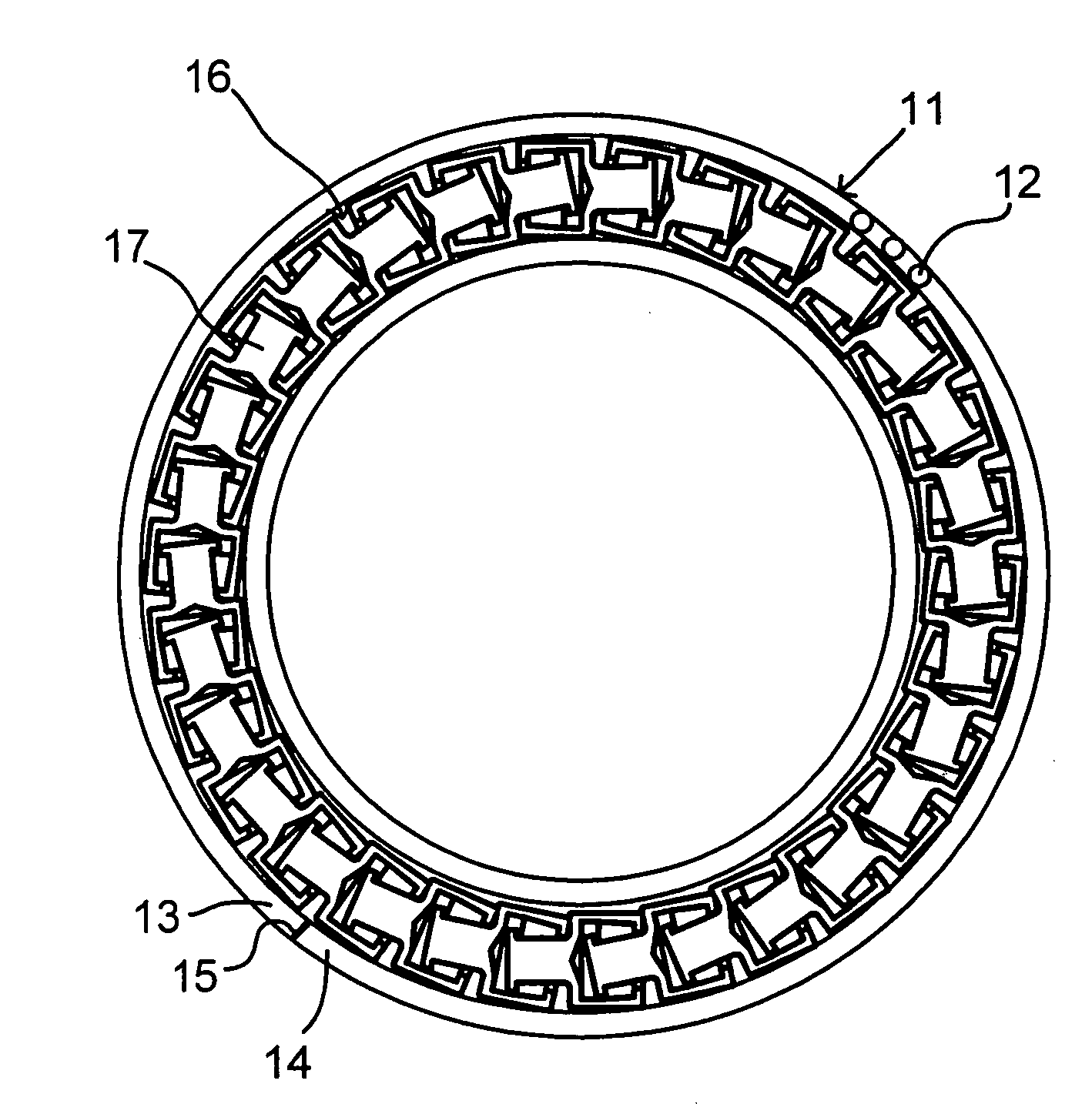

[0017]FIG. 1 shows a reinforcement ring 11 comprising an annular coil spring 12. The ends 13 and 14 of the coil spring 12 are joined before completion by soldering or gluing 15, as will be described below.

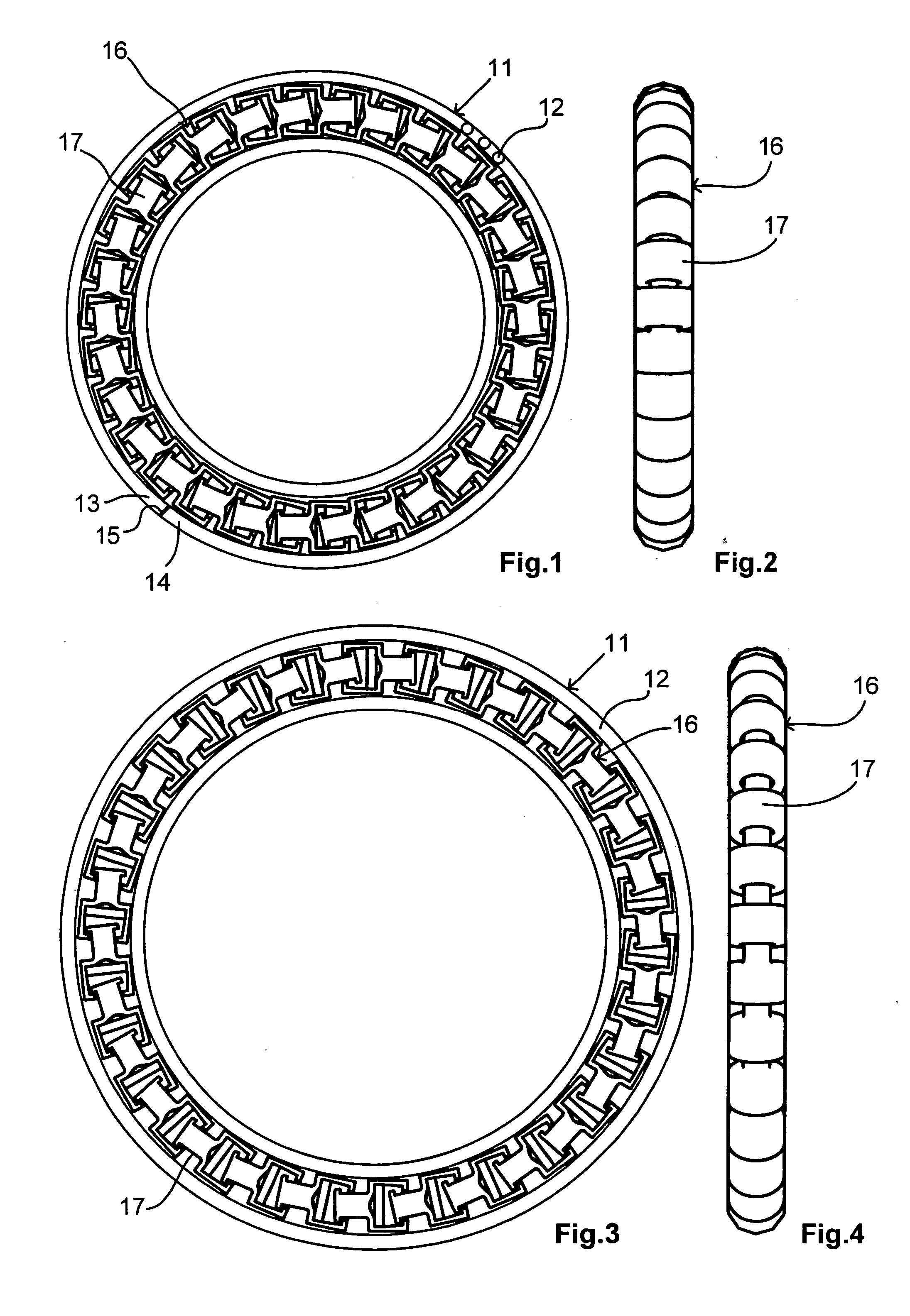

[0018] In the coil spring 12 a core unit 16 comprising a chain of core elements 17, are arranged, in the example 44 elements. The structure of the core elements 17 will be described in more detail with reference to FIGS. 5 and 6.

[0019]FIG. 2 shows the core unit 16 in its compressed form as used in the reinforcement ring in FIG. 1. Due to the function to be described below, the core elements 17 can be moved between a compressed position close to the adjoining core elements and an expanded position with a larger mutual distance.

[0020]FIGS. 3 and 4 show the reinforcement ring 11 and the core unit 16 in its expanded position.

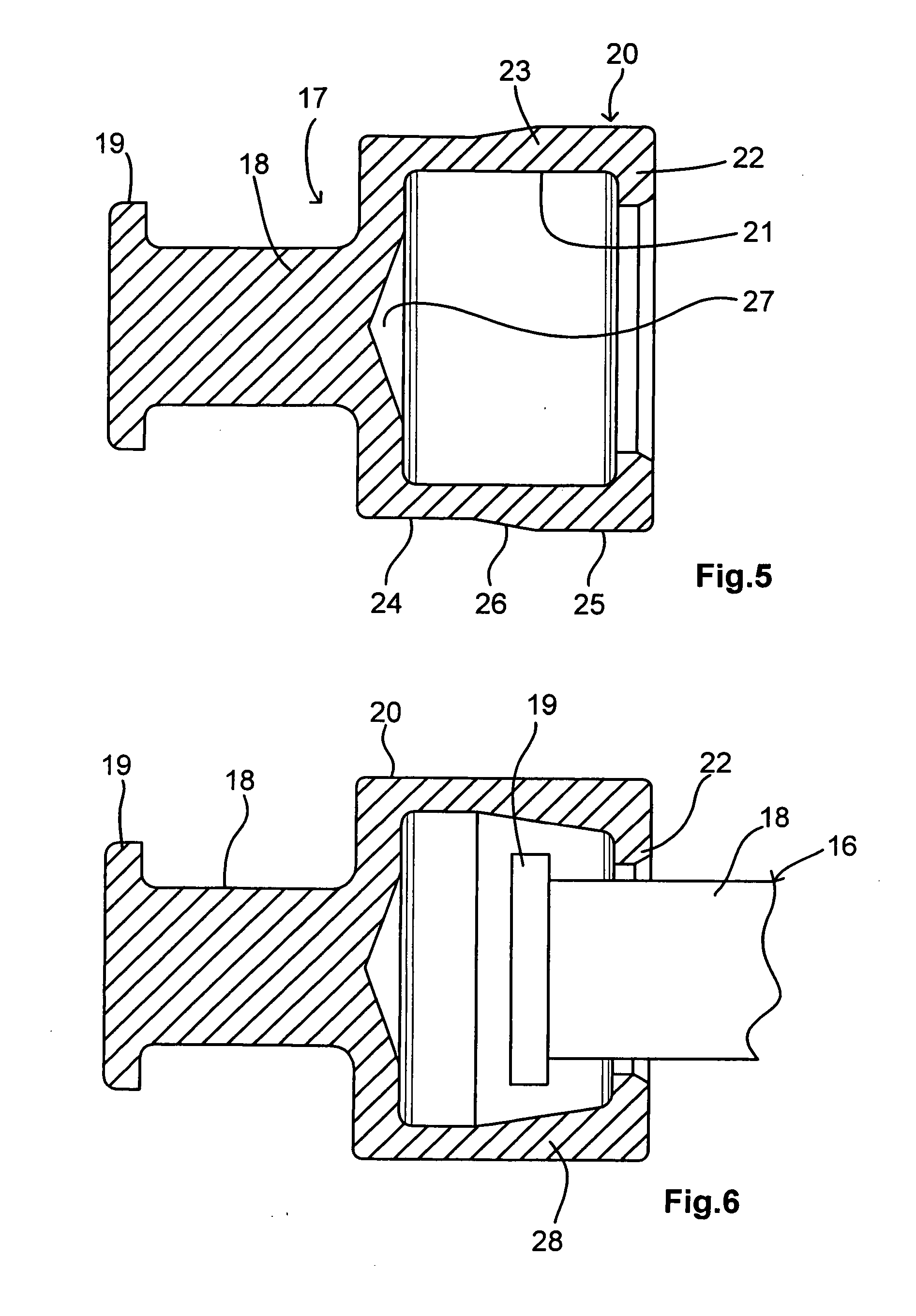

[0021]FIG. 5 shows a core element 17 in its pre-mounting form. The element 17 has a cylindrical shank 18 with a radial flange 19 at one end, and a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com