Fuel equalization system

a fuel equalization and fuel technology, applied in the direction of combustion types, combustion processes, burners, etc., can solve the problems of corresponding harmful buildup of co, inability of sensors of known systems to accurately control the desired air/fuel mixture, and inability to accurately control the flow or air inlet conditions of blocked air, so as to reduce the turbulence of blocked air flow, prevent leakage, and reduce the number of clips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

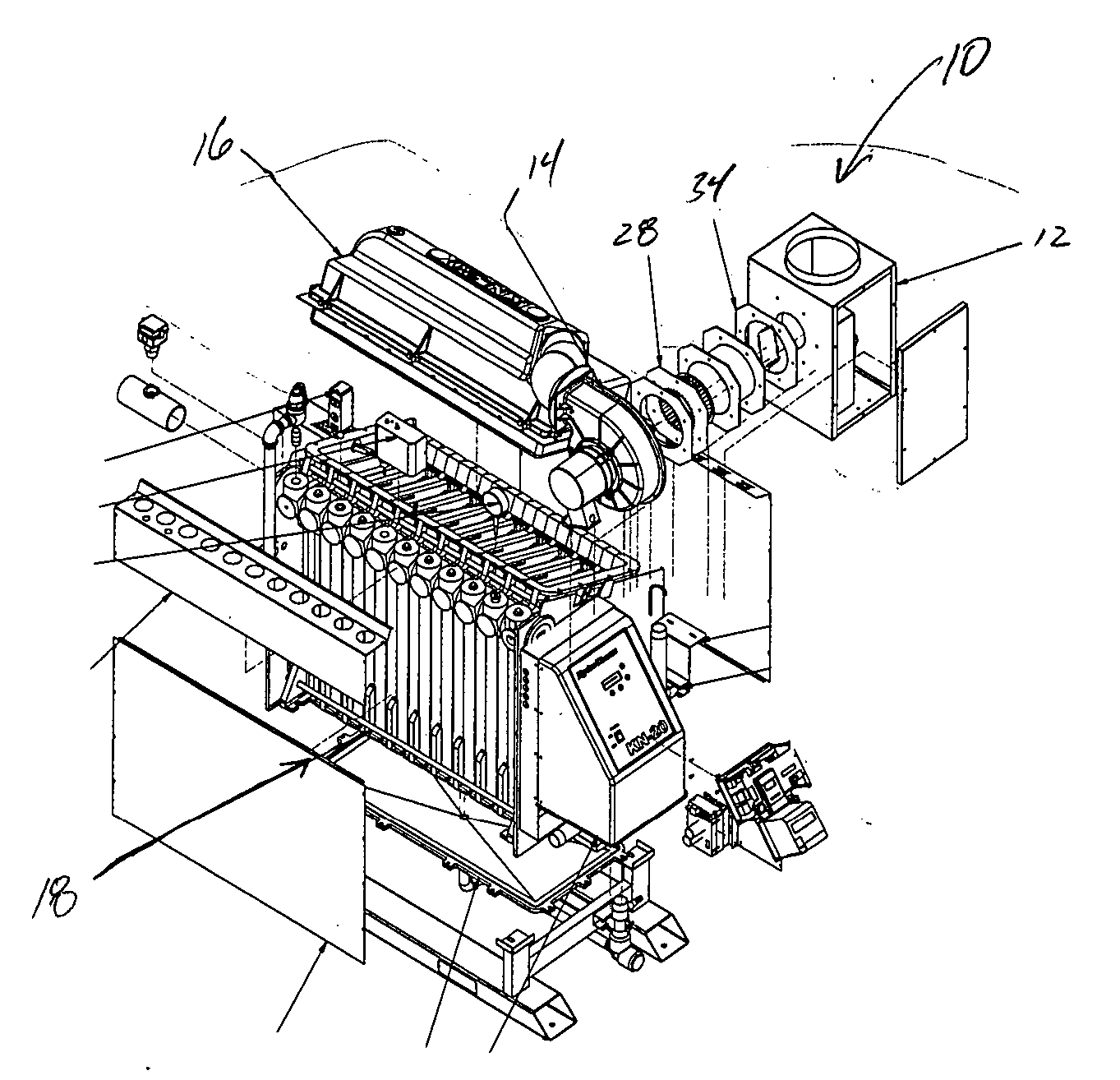

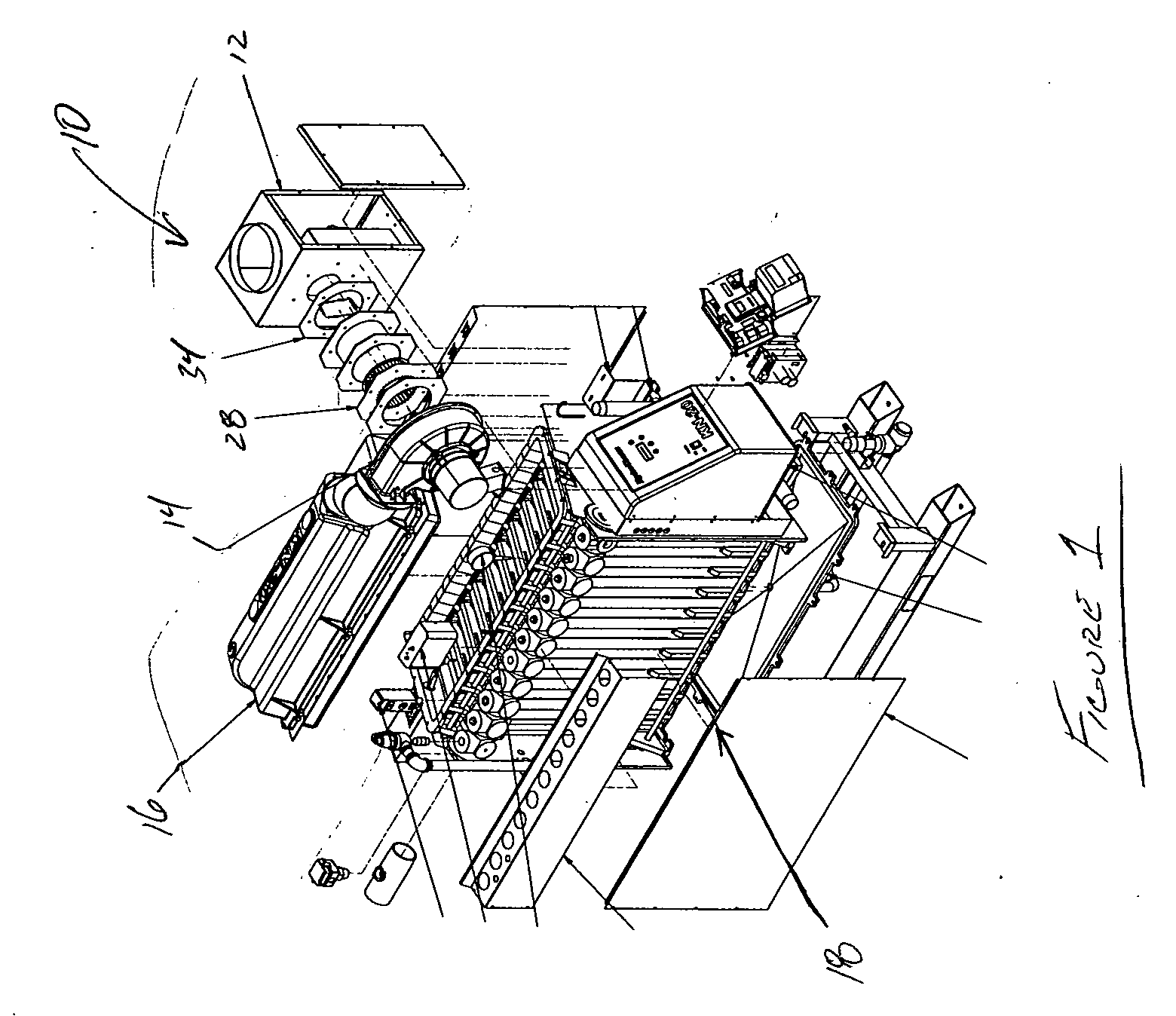

[0020]FIG. 1 illustrates an exploded view of a fuel equalization system 10, according to one embodiment of the present invention. As shown in FIG. 1, the fuel equalization system 10 includes a filter box 12 and a blower 14. An air / fuel stream is directed by the blower 14 to a burner assembly 16, which in turn is operatively connected to a boiler apparatus 18.

[0021] It will be readily appreciated that while the boiler apparatus 18 has been described in connection with FIG. 1, the present invention is not so limited in this regard as the blower 14 may be connected to any suitable apparatus without departing from the broader aspects of the present invention.

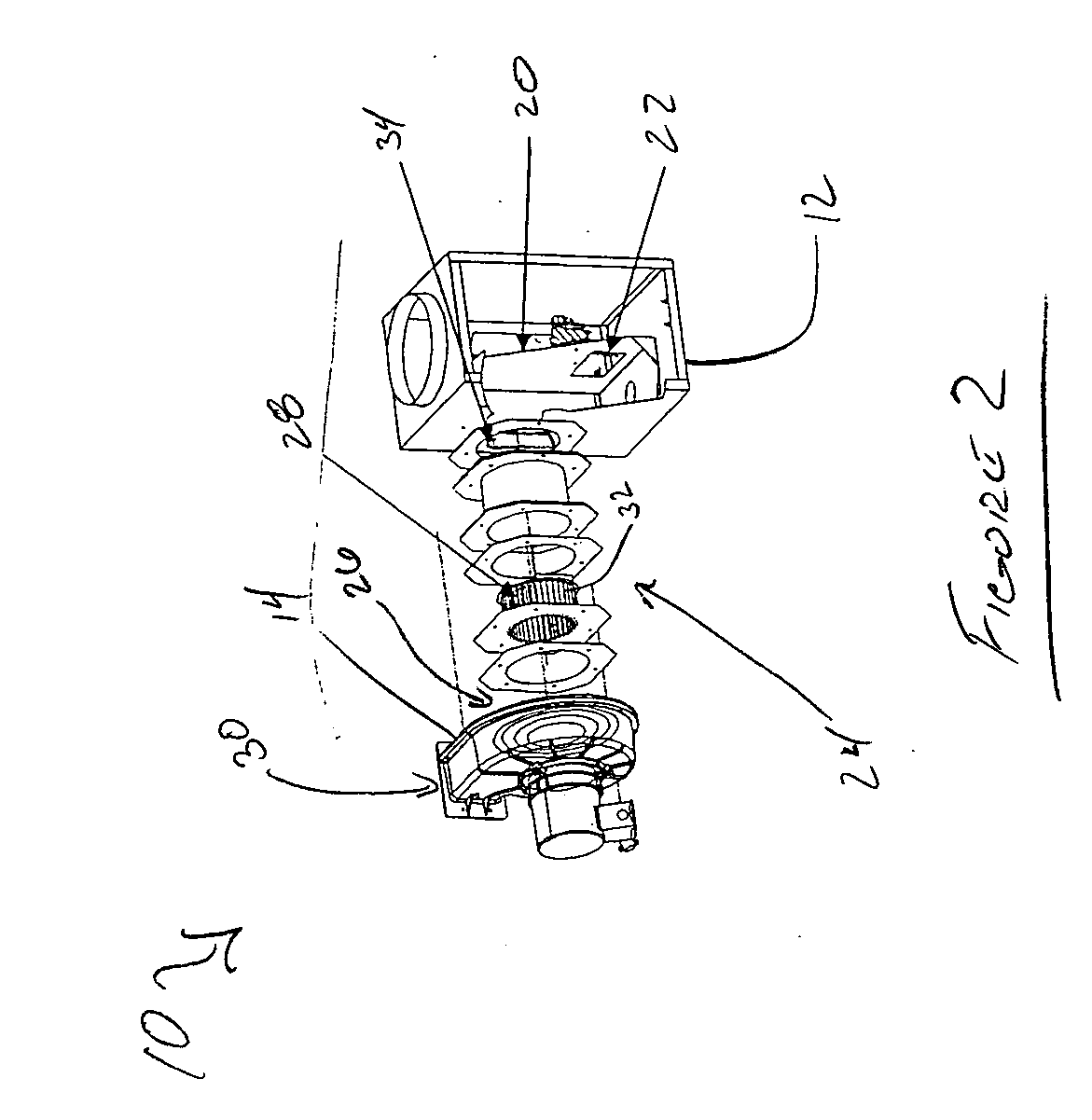

[0022]FIG. 2 illustrates the fuel equalization system in isolation. As shown in FIG. 2, the filter box 12 defines an inner box 20 having an air orifice and fuel entry 22. A duct section 24 is oriented between the filter box 12 and the blower 14. An air stream and a fuel stream are directed through the air orifice and fuel entry 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com