Apparatus and method for static resistance training

a training apparatus and static resistance technology, applied in the field of static resistance training equipment, can solve problems such as pressing against fully static devices and structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0064] In the machine a body group device, lat pull, bench press, leg press or other form of apparatus adapted for receiving a force applied by the user, is configured with the action device. The action device is defined herein as being the movable part on a standard weight machine, which is configured for static or semi-static retention on this apparatus.

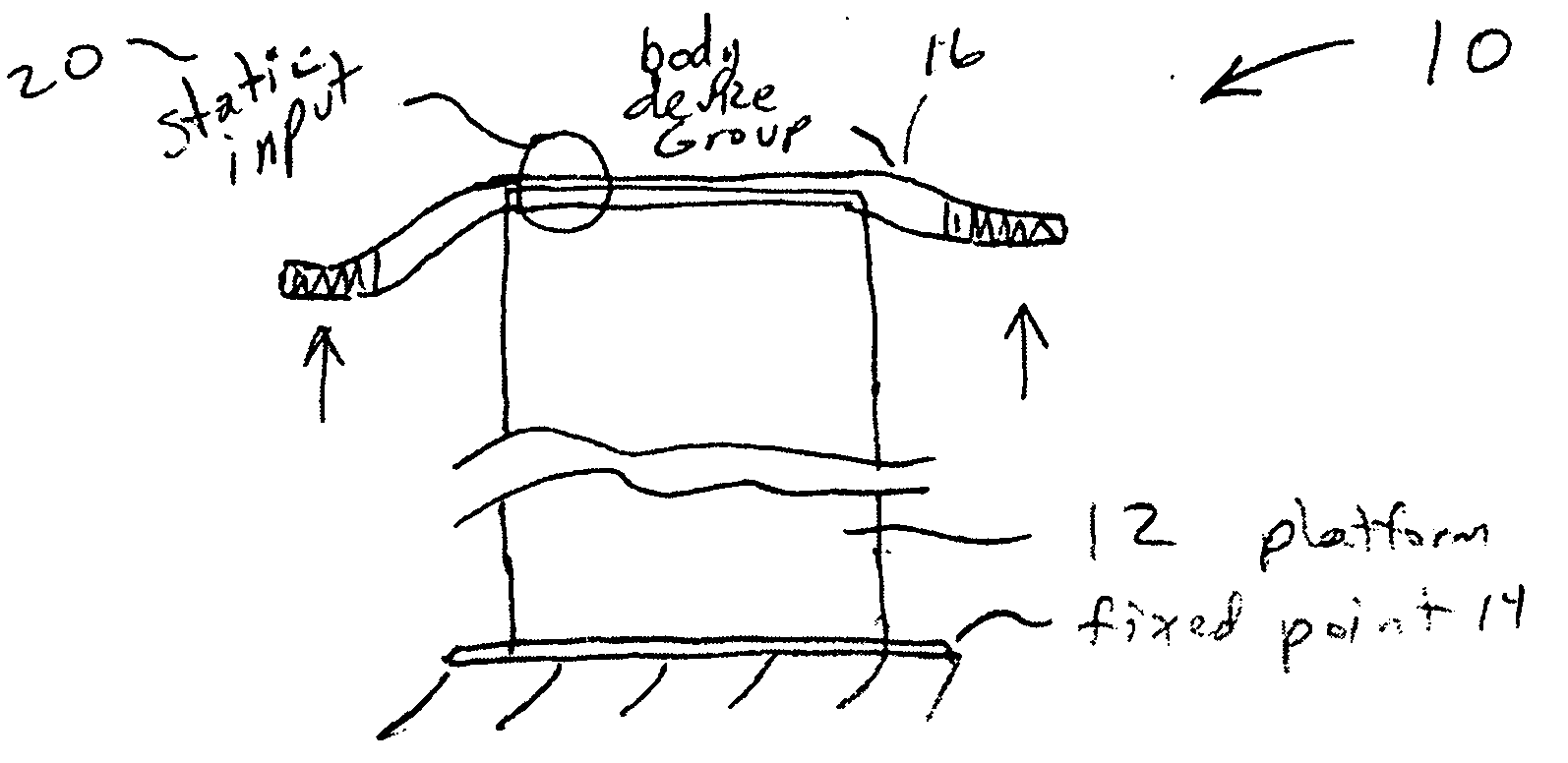

[0065]FIG. 1 is an example of the static training device 10, having a base 12 upon fixed platform 14. A body device group element 16 is shown with semi-static input element 20. In this mode semi-static input element 20 is adapted for providing a limited compliance adjustment to control the feel when pressure is applied to the body device group 16.

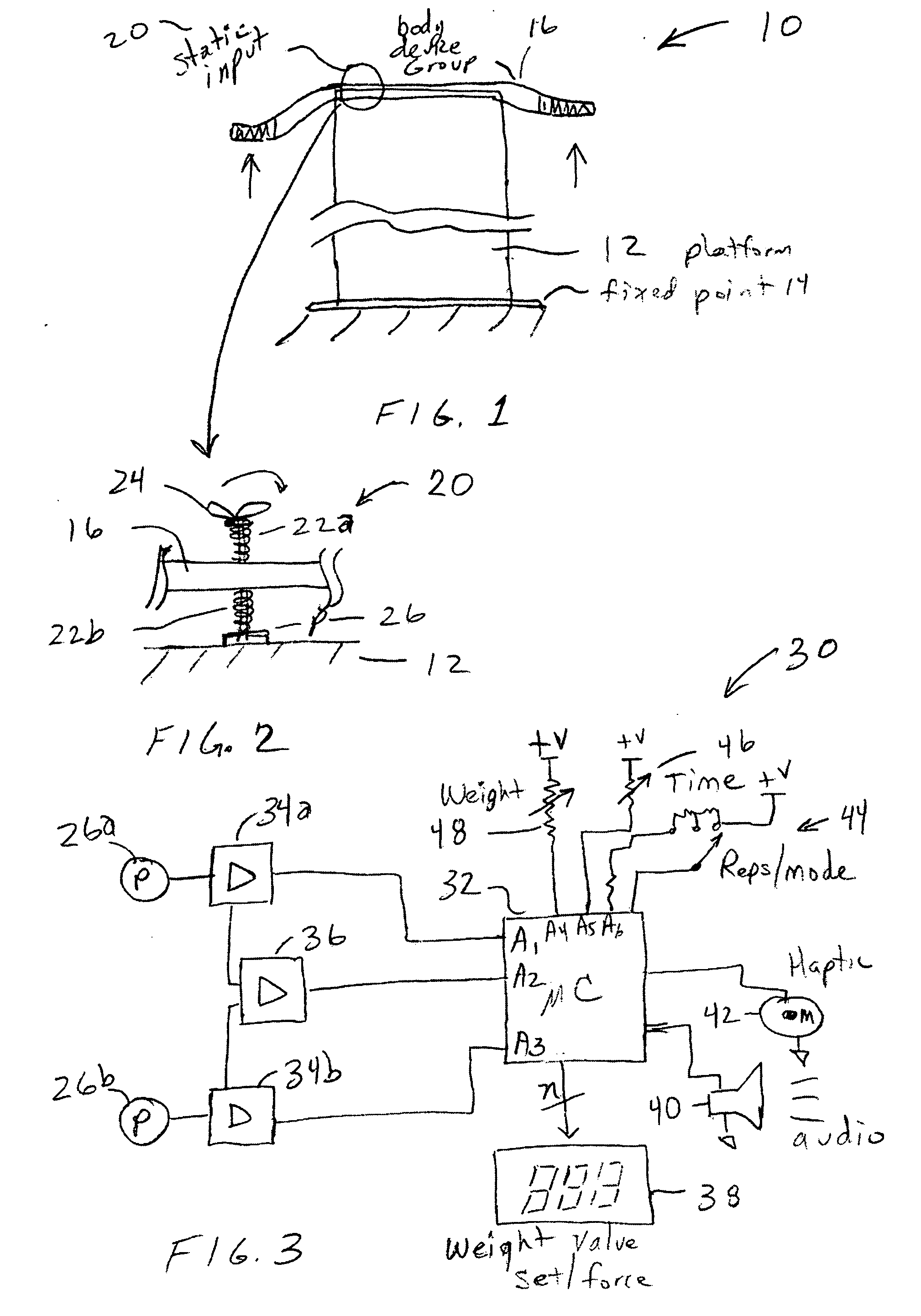

[0066]FIG. 2 illustrates an embodiment of adjustable feedback mechanism. In this simple illustration body device group 16 contains a bar which is shown mounted with compliant elements 22a, 22b upon retention member 24 coupled to sensor 26, which is adapted for sensing static force / pressur...

embodiment 50

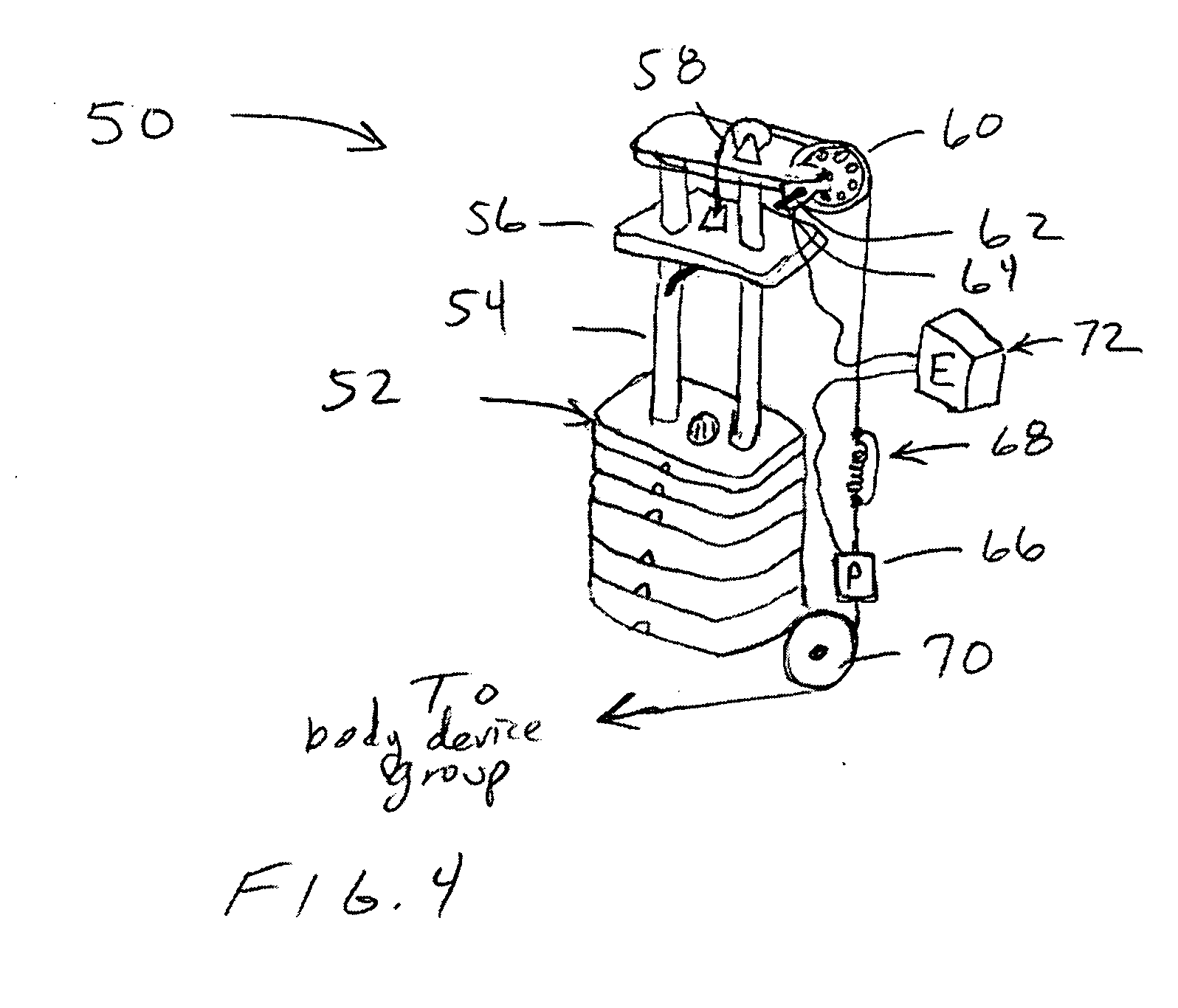

[0071] In FIG. 4 an embodiment 50 of a static force registration device is incorporated within a conventional non-static training devices, such as those incorporating movable weights. In this manner the devices can be used for both static training and dynamic training. It will be appreciated that the system can be preferably “locked” at a given position for static training wherein the user can practice static force application at any desired position along the normal travel path of the machine. For example locked so as to apply force near the arms fully-extended position, or any desired position along the range of conventional motion.

[0072] By way of example and not limitation, a weight stack is 52 shown adapted for being conventionally displaced along track 54. A first weight plate 56 is shown selected, such as via a weight selection pin, and moved to a desired position for static training. In this example the first plate is moved in response to a cable 58, such as through pulleys,...

embodiment 10

[0113]FIG. 5 illustrates an embodiment 10 of the electroactivated starter pistol having a housing 12 that is not readily confused with a weapon and yet it has a handle 14 with a trigger 16, such that pulling the trigger activates the starting sequence of the device. A base 18 is shown into which a pyro strip 20 can be inserted. A user interface 30 is shown with selectors for setting the mode of operation, timing cadence, level of randomness, and other aspects of operation. A small display 32 is shown (e.g., electronic ink, LED, LCD, etc.) for displaying any desired status information. Alternatively, or additionally, discrete status indicators are utilized such as LEDs for indicating state, mode, and so forth.

[0114]FIG. 6 depicts an example of the percussion device strip, for example pyrotechnic (pyro) strip 20, having a base material 21 which forms a printed circuit for electrically establishing connections with each pyro element 22, (i.e., plastic, paper, phenolic, fiberglass, or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com