Portable thermal treatment and storage units for containing readily accessible food or beverage items and methods for thermally treating food or beverage items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

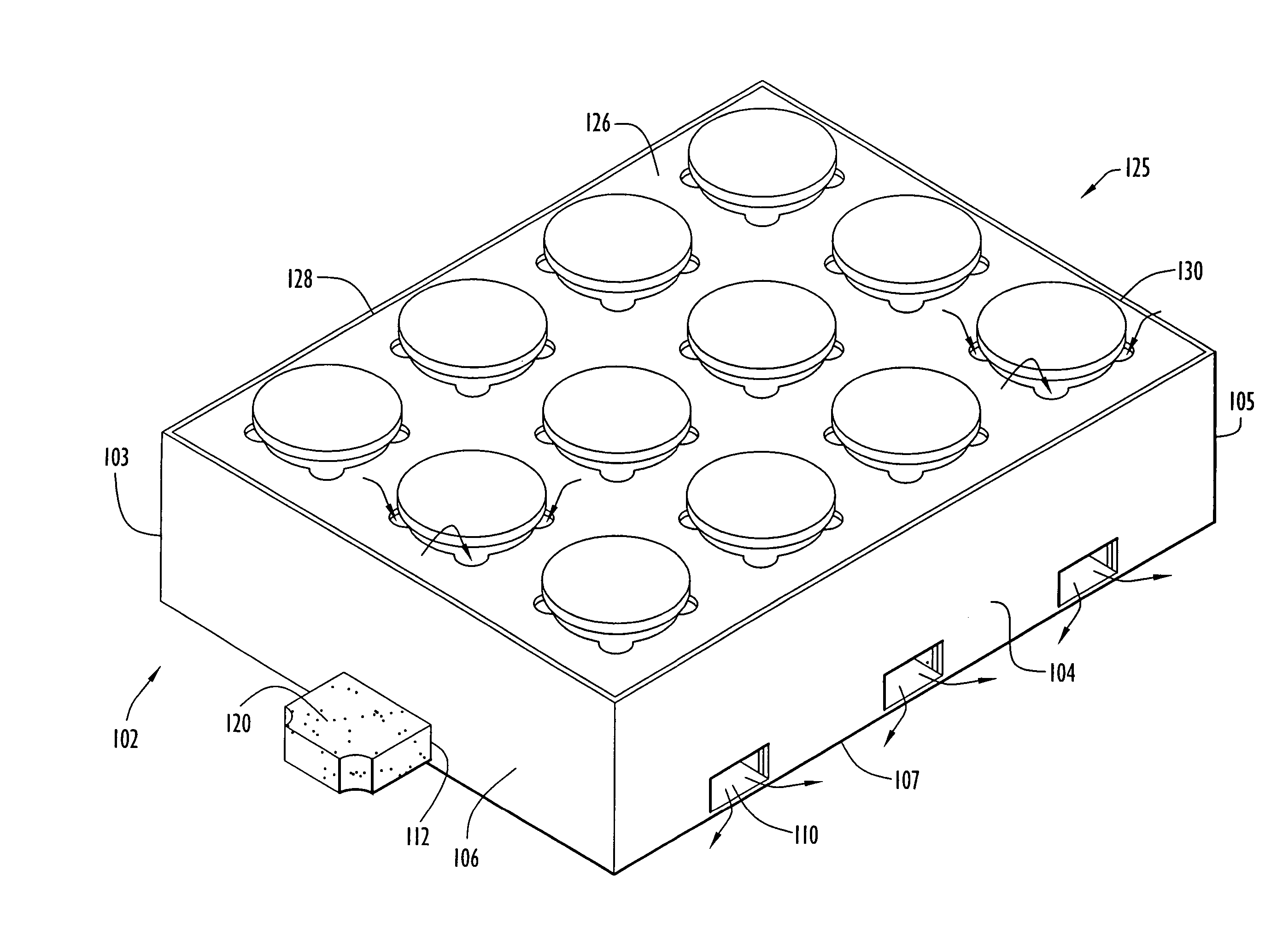

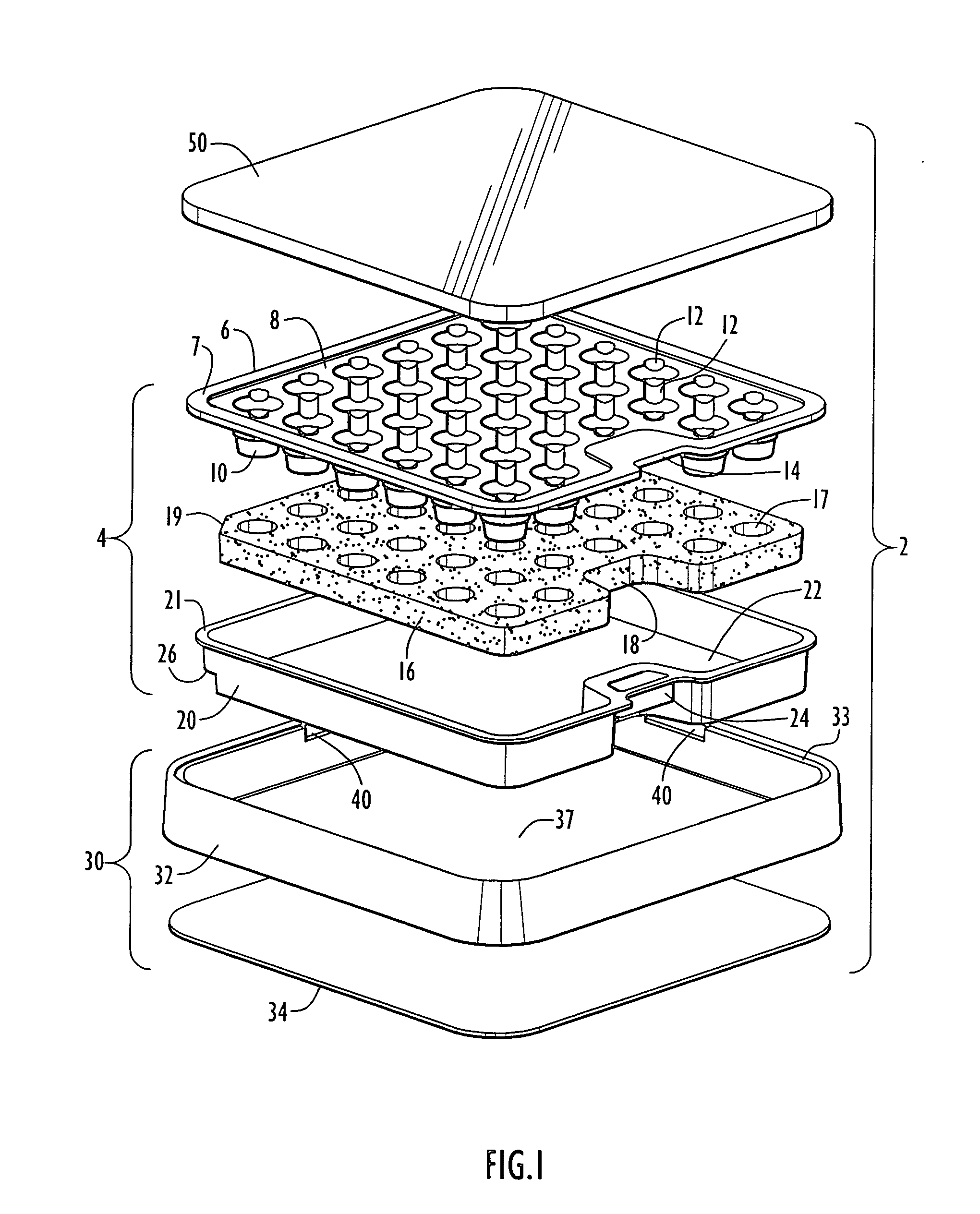

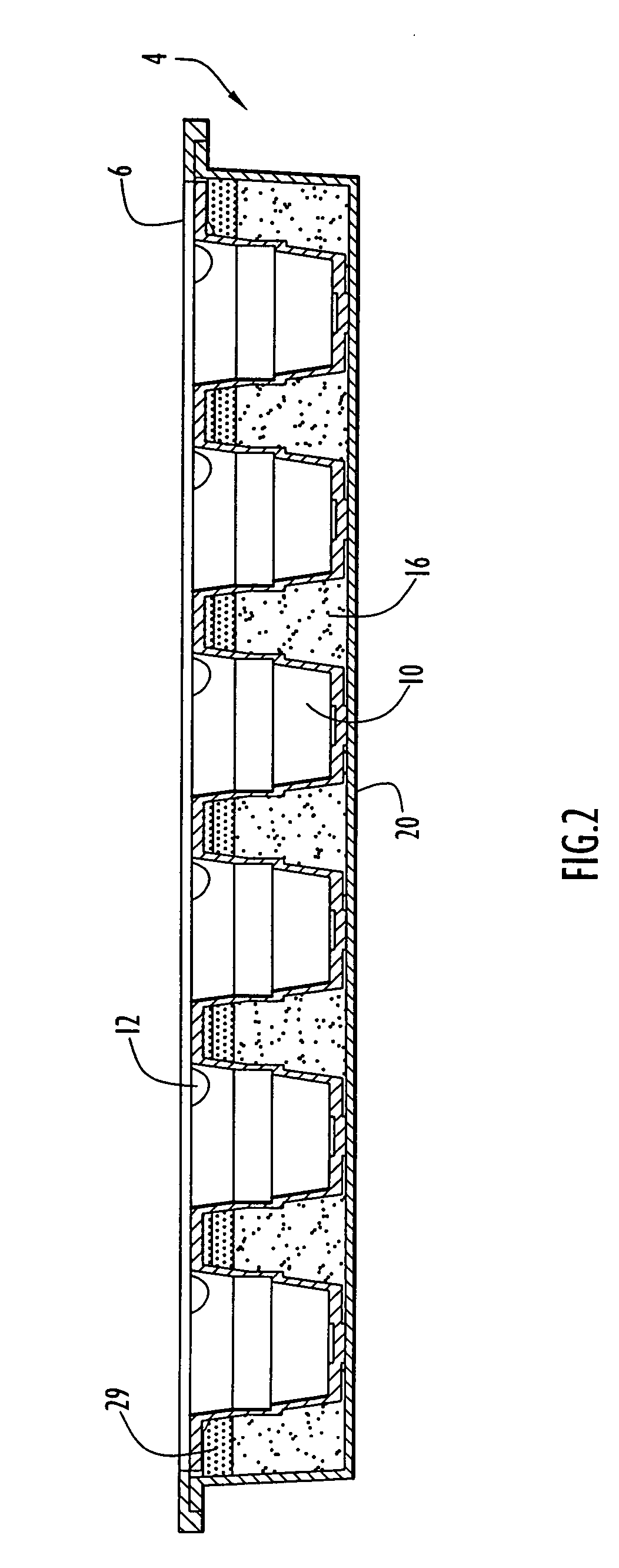

[0033] In accordance with the present invention, a portable thermal treatment and storage device or unit is provided that is capable of converting frozen or non-frozen food or beverage items into a partially frozen state and / or maintaining food or beverage items in a partially frozen or any other desired state and within a desired temperature range for a selected time period without the requirement of electrical energy.

[0034] In one embodiment of the invention, a portable refrigeration and insulation unit includes a cartridge that effectively insulates and / or refrigerates food items stored in the cartridge at desired temperatures. The cartridge includes an insulating material and / or a heat transfer material that provides effective heat transfer between portions of the cartridge and the food items stored within the cartridge so as to maintain the food items at the desired temperatures. In addition, the unit includes an outer frame or case that is configured to receive the cartridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com