LED (light emitting diode) light fixture with efficient light distribution

A technology of LED lamps and LED lamp beads, which is applied to semiconductor devices, light sources, and shading of light-emitting elements, which can solve problems such as low value, useless light distribution, and complex structure, and achieve improved uniformity, air flow, and The effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

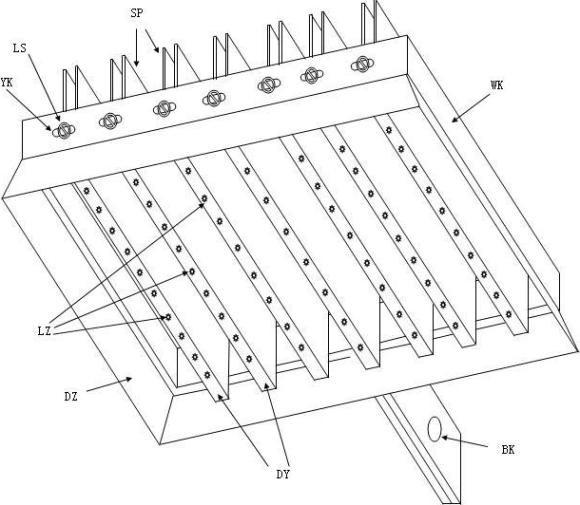

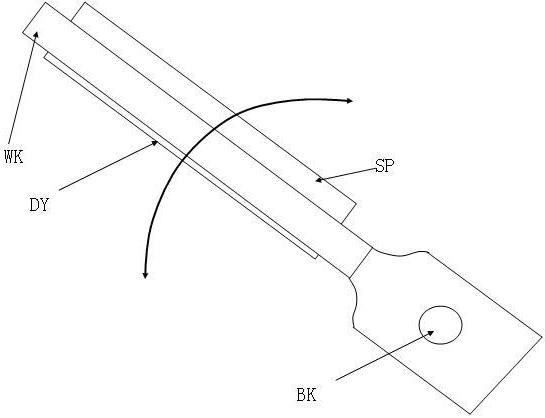

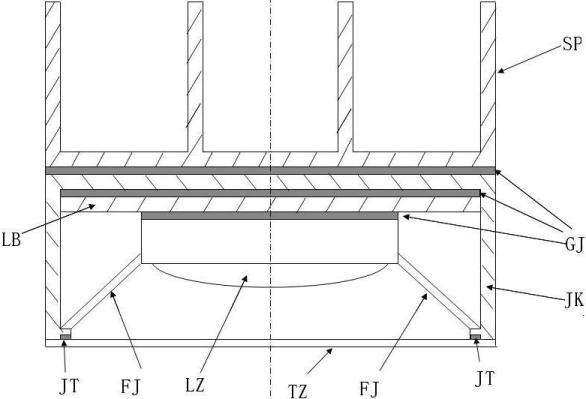

[0035] exist figure 1 Among them, WK is the outer frame, DZ is the cut-off cover, LS is the adjustment screw, YK is the waist hole, BK is the hole of the outer frame connecting handle, DY is the lamp bead unit, SP is the heat sink, and LZ is the LED lamp bead.

[0036] The outer frame WK is provided with an outer frame connecting handle, and the outer frame connecting handle is provided with a hole BK. The outer frame connecting handle is connected with the arm of the light pole through the hole BK and fasteners. The outer frame WK can be wound around the hole BK through the connecting handle. The fastener turns.

[0037] Each lamp bead unit body DY is located in the outer frame WK and parallel to the direction of the connecting handle. All the lamp bead unit bodies DY are symmetrically distributed in the outer frame WK on the center line of the outer frame WK parallel to the road transverse direction, and the lamp bead unit bodies from the inner row To the outer row of lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com