Automatic monitor sliding system

a monitor and automatic technology, applied in the direction of instruments, electrical apparatus casings/cabinets/drawers, instruments, etc., can solve the problems of dust, water permeation, mistouching input, etc., to prevent dust, water permeation, and mistouching input, and high sliding radian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

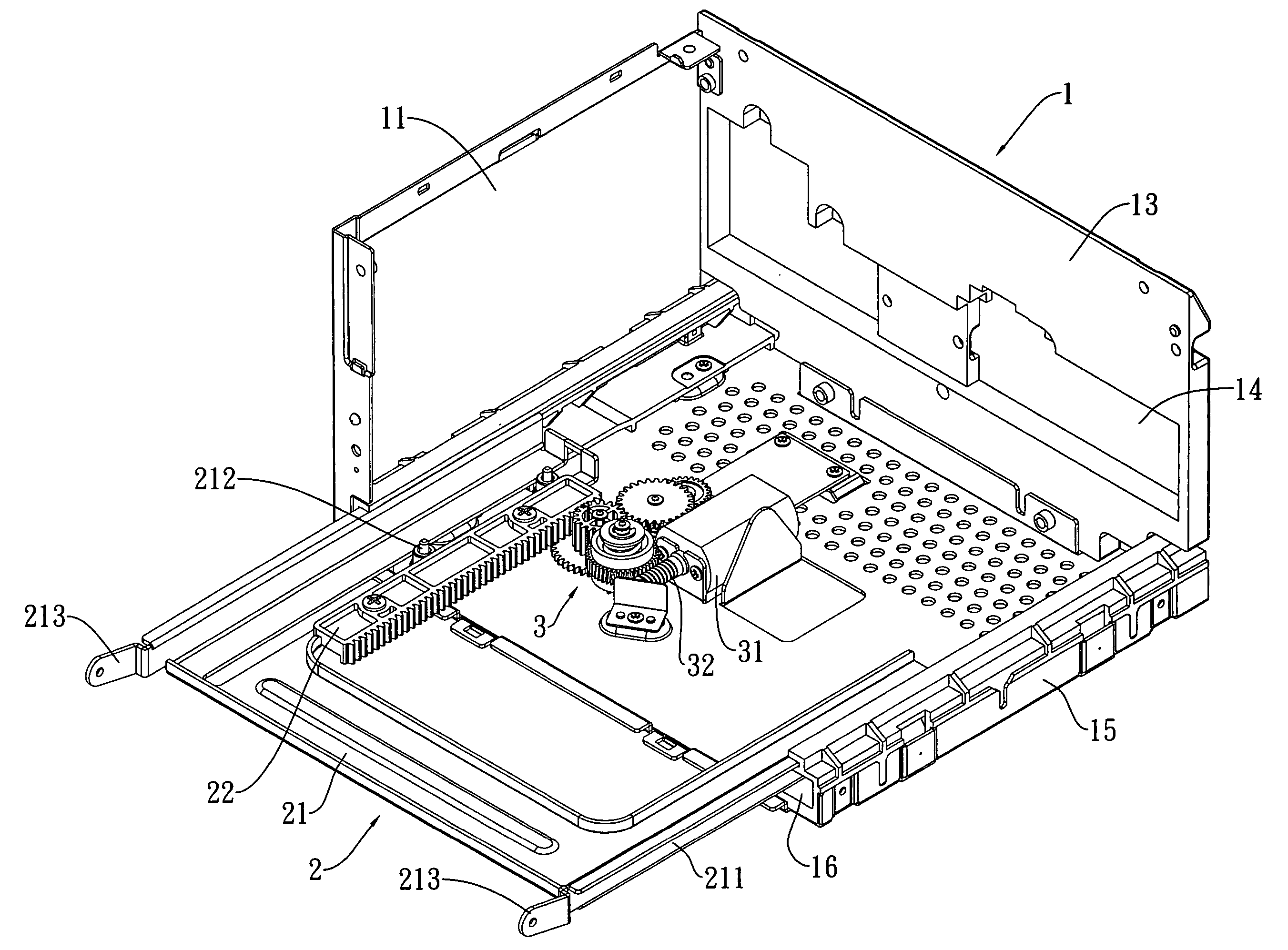

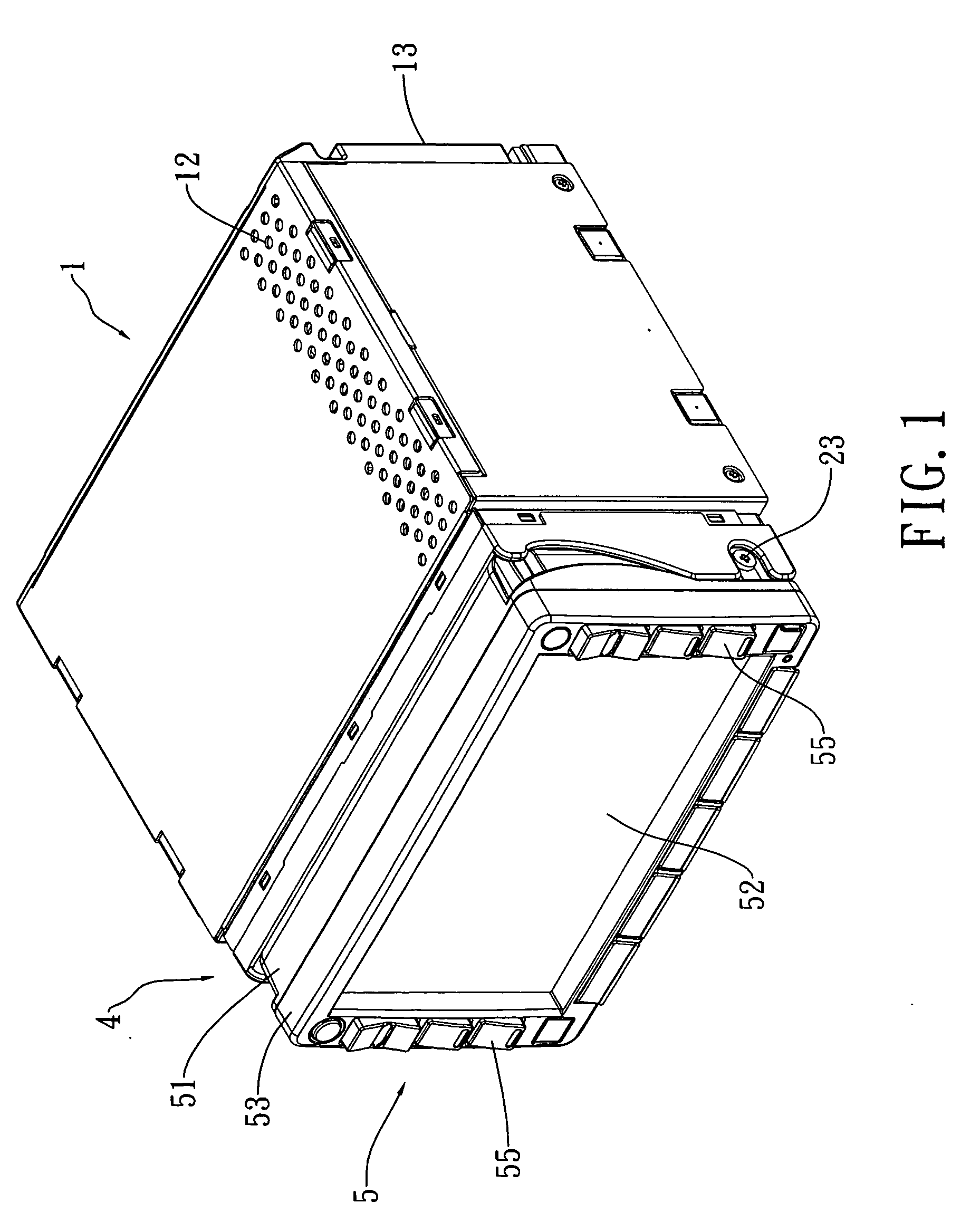

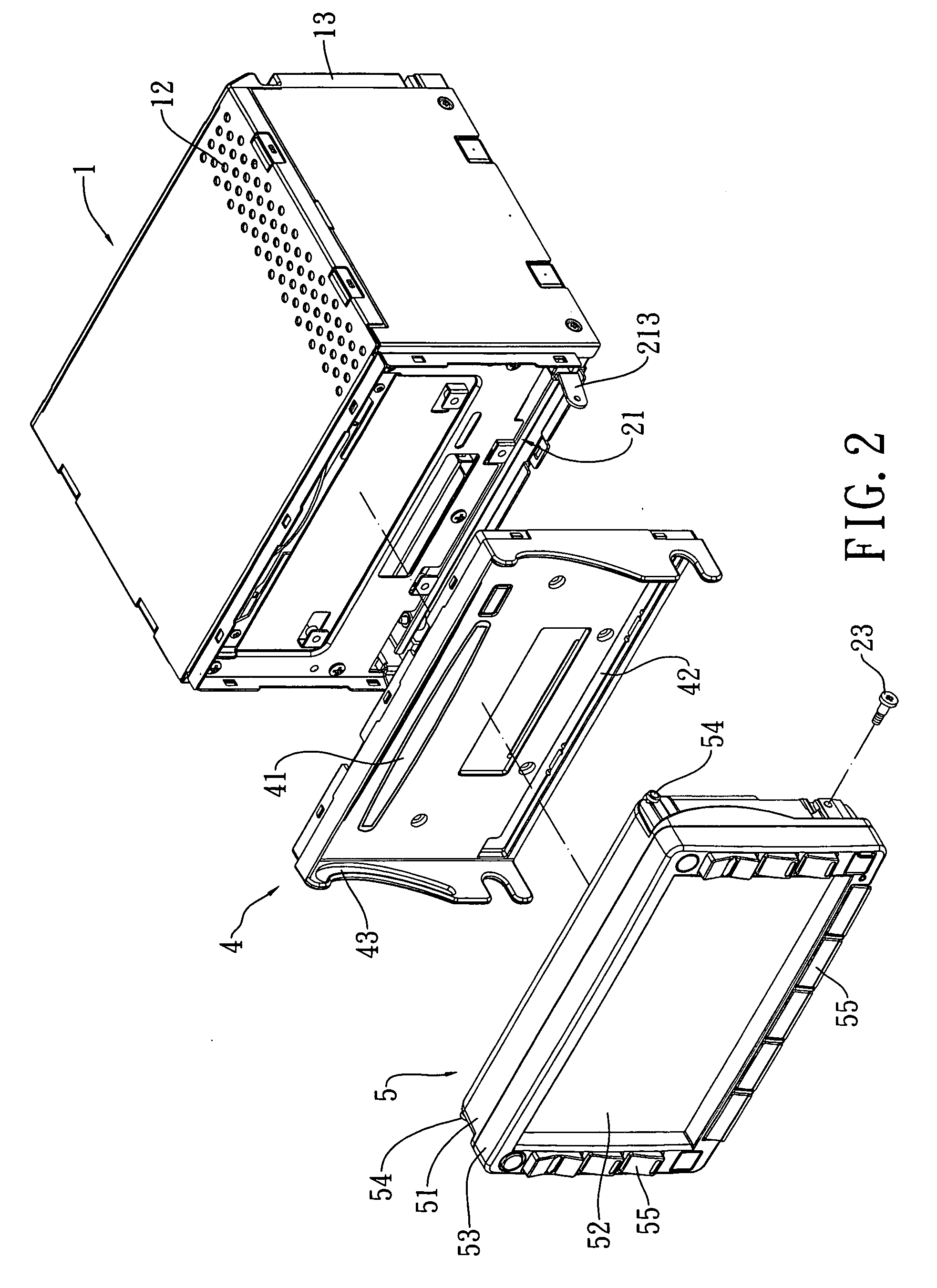

[0021] Referring to FIG. 1 to FIG. 3, an automatic monitor sliding system of the present invention is shown. The automatic monitor sliding system comprises a machine case 1, a slidable structure 2, a monitor mounting plate 4, and a monitor structure 5.

[0022] The machine case 1 comprises: a reception chamber 11 on which components can be mounted for working; a plurality of heat-dispersing holes 12 on a top case and a bottom case for dispersion of the heat from the inside components to prevent excessive heat from causing the inside components unworkable; a heat-dispersing plate 13 having a transmission interface 14 to which a related signal source is connected for signal transmission; a base 15; and a guide trench 16 mounted on each side of the base 15. The guide trenches 16 are designed in the form of a bar to match the sliding distance.

[0023] The slidable structure 2 is mounted inside the machine case 1 and mounted on the interior lower portion of the machine case 1. The slidable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com