Supporting plate, apparatus, and method for stripping supporting plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

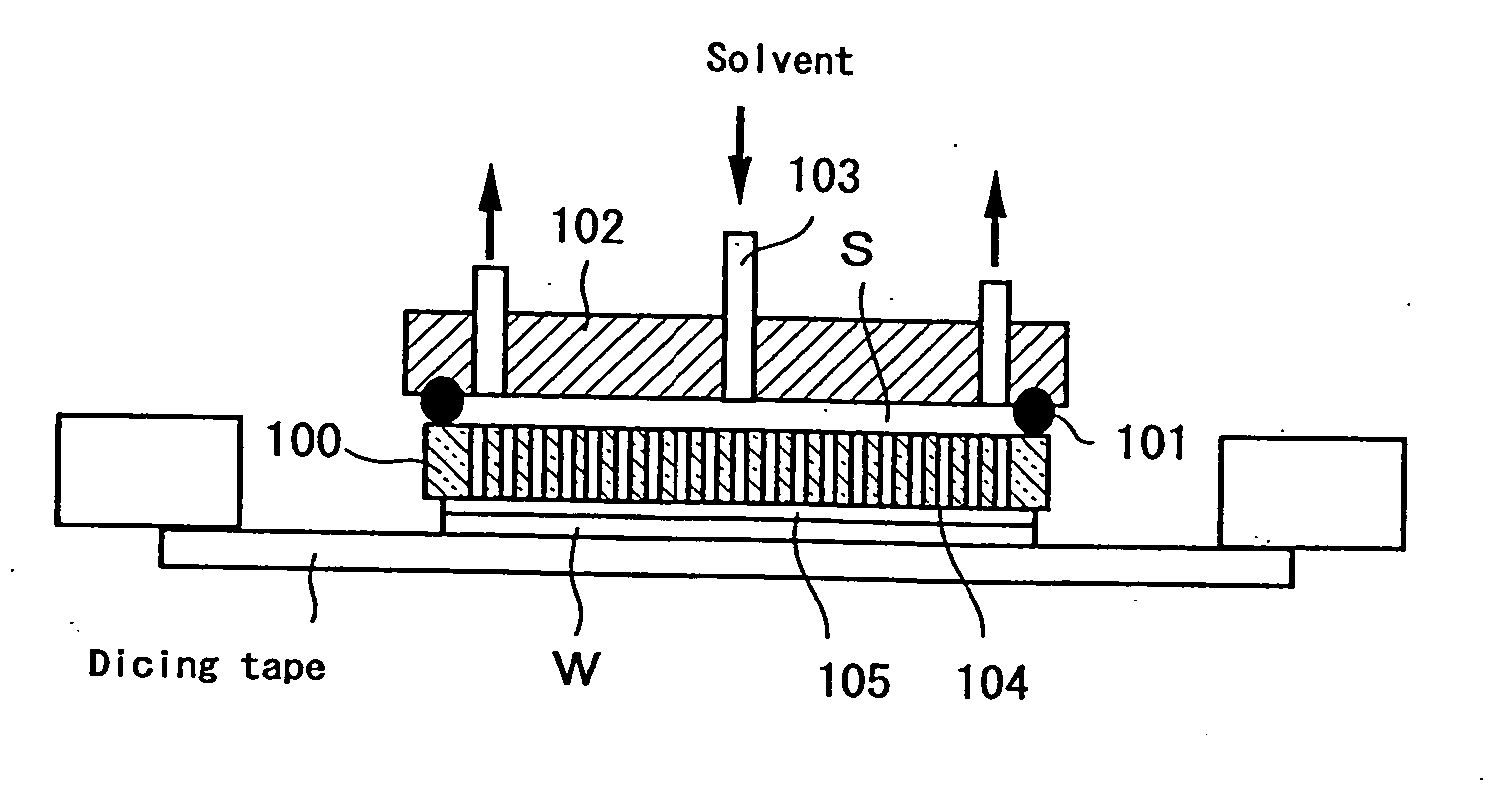

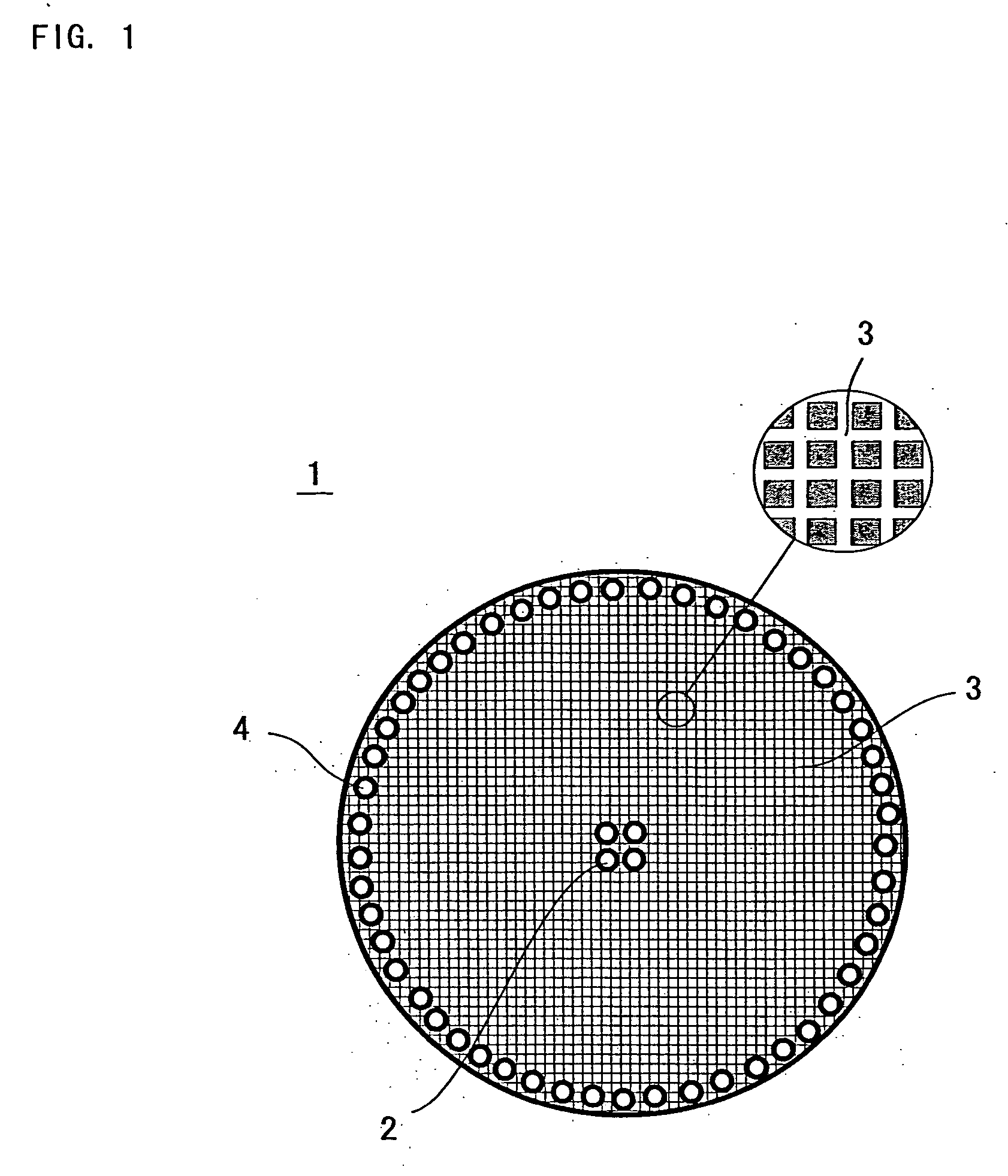

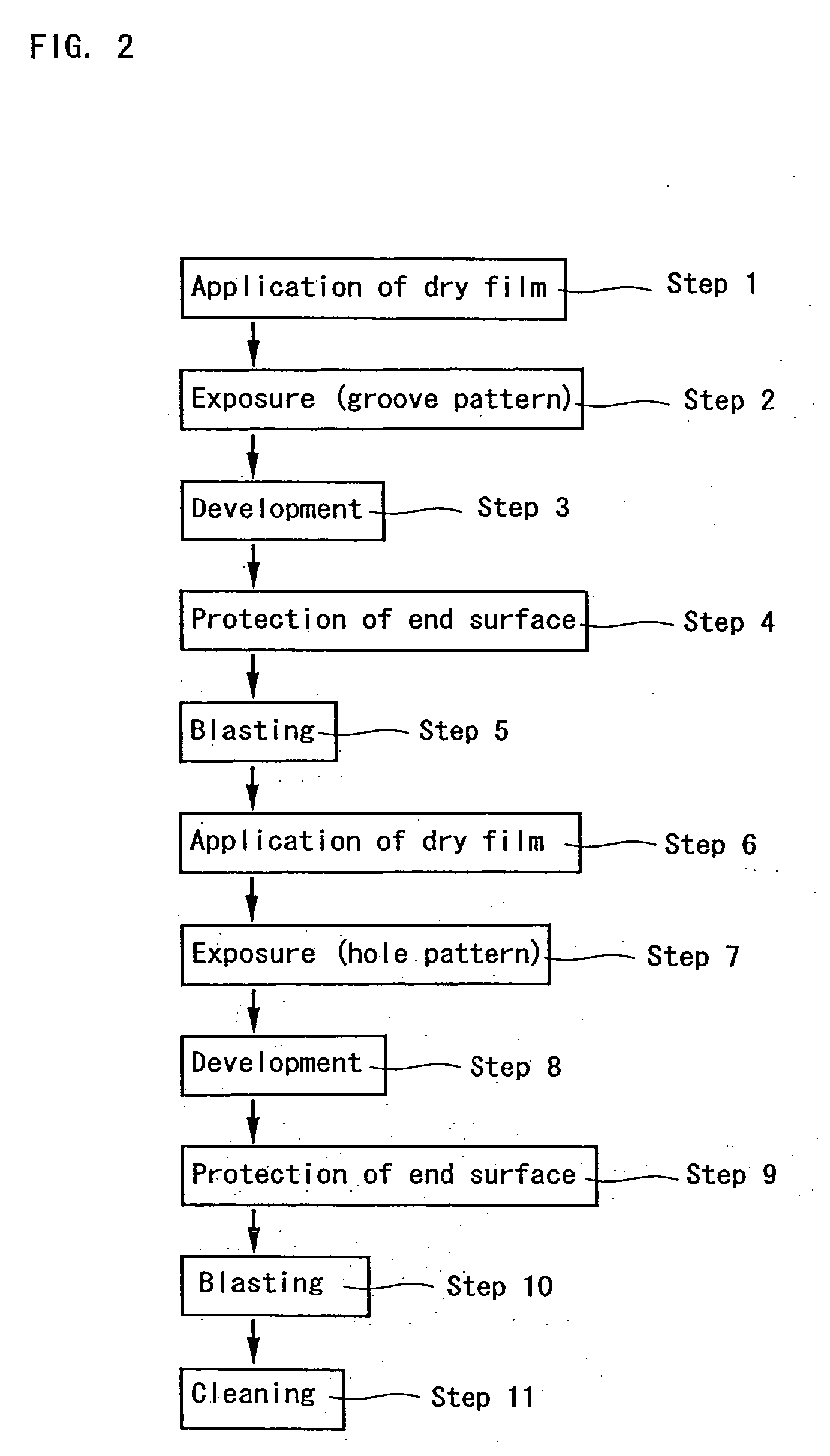

[0043] Embodiments of the present invention will be described below with reference to the attached drawings. FIG. 1 is a schematic view showing an embodiment of a supporting plate according to the present invention, and FIG. 2 shows the process for forming a supporting plate.

[0044] A supporting plate 1 according to the present invention shown in FIG. 1 is made of a glass plate, a ceramic plate or a metal plate.

[0045] A circuit-formed surface of a semiconductor wafer W is bonded to one of the surfaces of the supporting plate 1 by using an adhesive, which is not shown in the drawing.

[0046] According to the present invention, the supporting plate 1 has a unique structure as described below.

[0047] A first penetrating hole 2 is formed in a substantially central portion (center) of the supporting plate 1 so as to penetrate in the thickness direction. A plurality of first penetrating holes 2 may be formed, and for example, four penetrating holes 2 are formed in FIG. 1. However, the num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com