Textured vinyl pull cap

a pull-cap and textured technology, applied in the field of pull-caps, can solve the problems of inability to effectively serve the sealing or capping function of commercially produced vinyl end caps, difficult to remove the end cap from engagement with an article, and tend to occur with some frequency, so as to enhance the ease of installation and/or and facilitate the removal of the end cap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

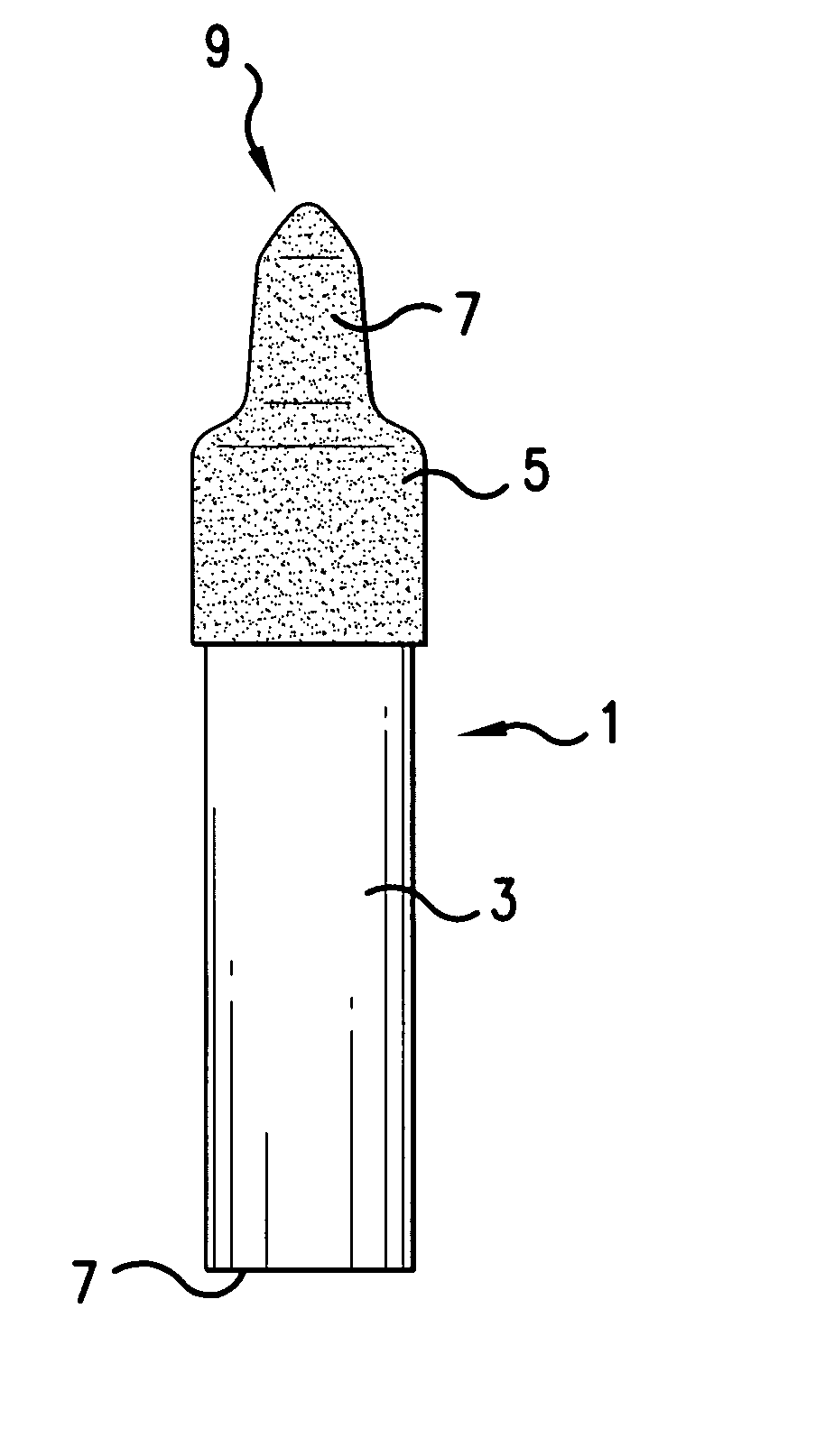

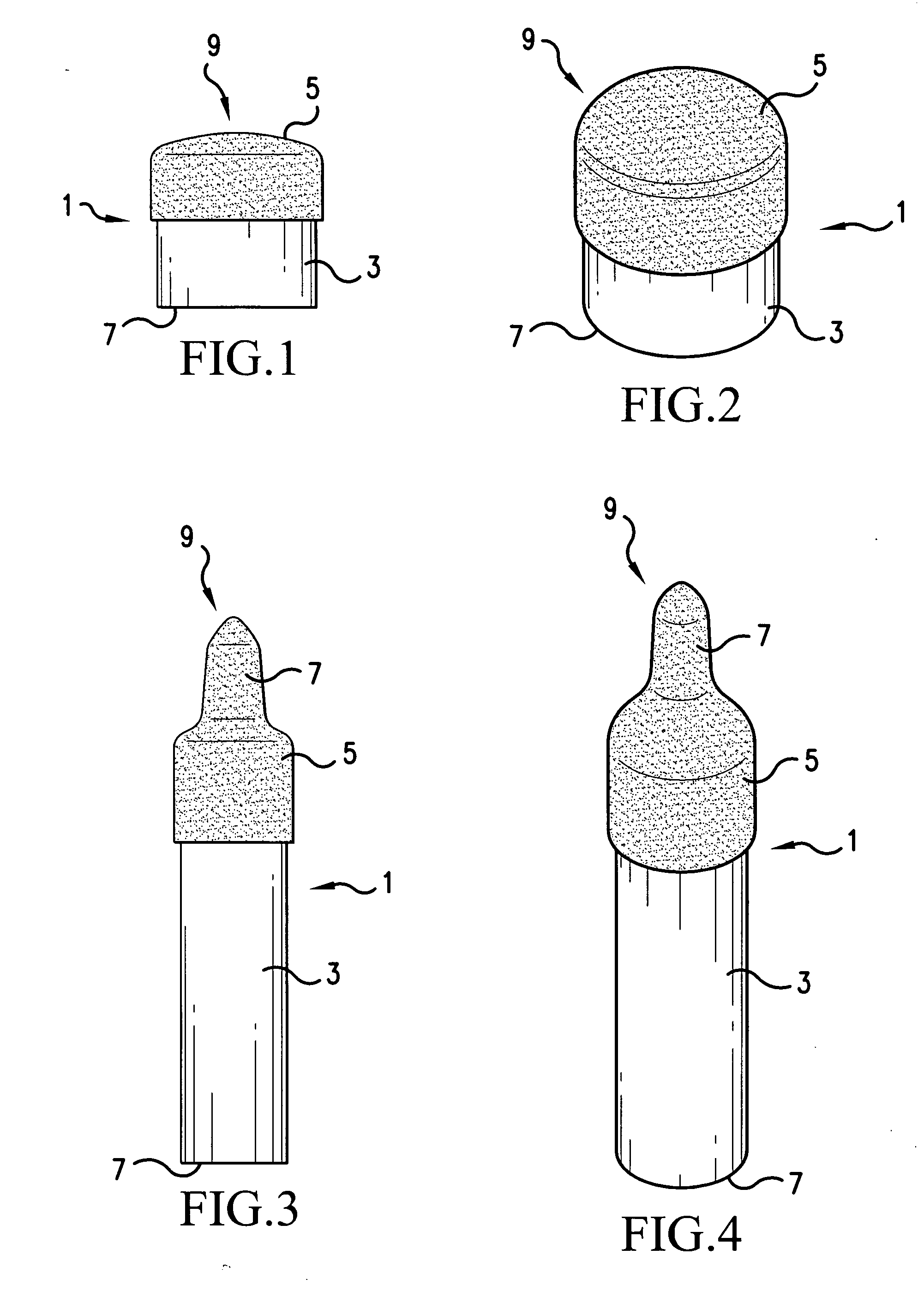

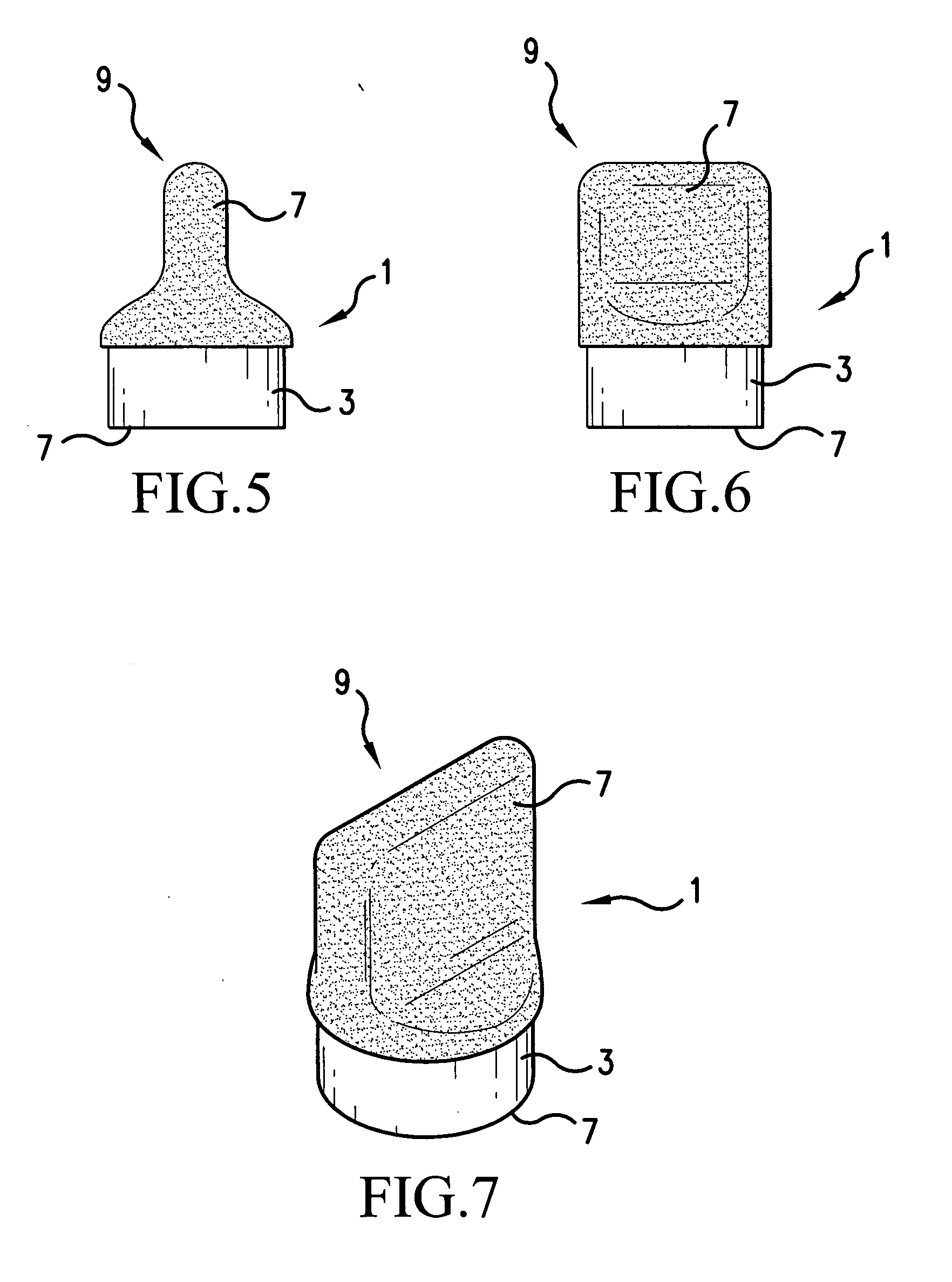

[0014] The invention will be described in connection with FIGS. 1-7.

[0015] The end cap 1 of the present invention is made by dip molding. Dip molding processes are well known in the art, and have been used for decades to produce vinyl-based plastic articles.

[0016] In a dip molding process, a heated mold form or mandrel is dipped into a plastisol bath whereupon a layer of gelled (fused)_plastisol forms about the mandrel. The coated mandrel is removed from the plastisol dipping tank and the coated layer cured, resulting in a molded article corresponding in configuration to the configuration of the mandrel employed. For instance, when a cylindrical mandrel (or pin) is employed, a tubular article with a closed bottom can be produced. Beverage containers, bicycle handles, gloves and tubular hose bend restrictors are but a few of the products that are presently produced by dip molding by use of a variety of mandrel configurations.

[0017] The mandrel may be comprised of any suitable meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com