Decanting bottle and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

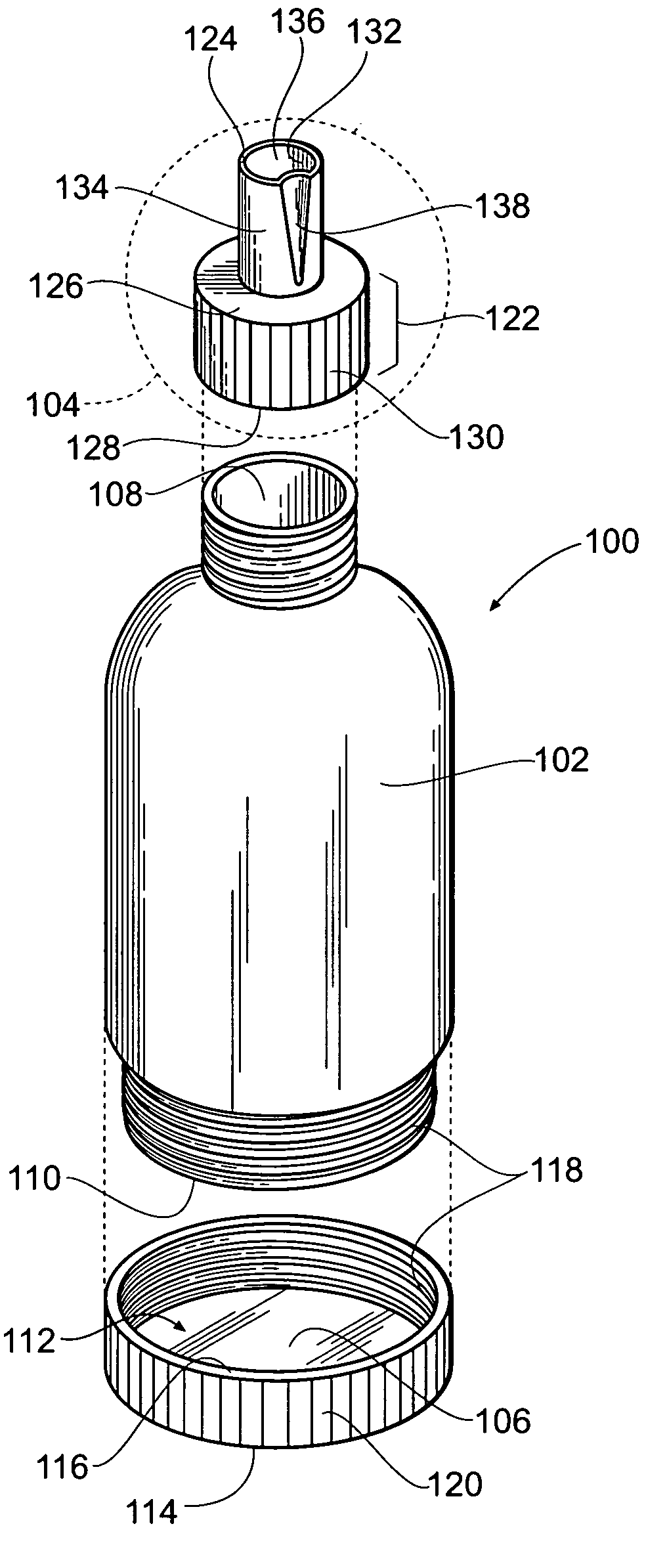

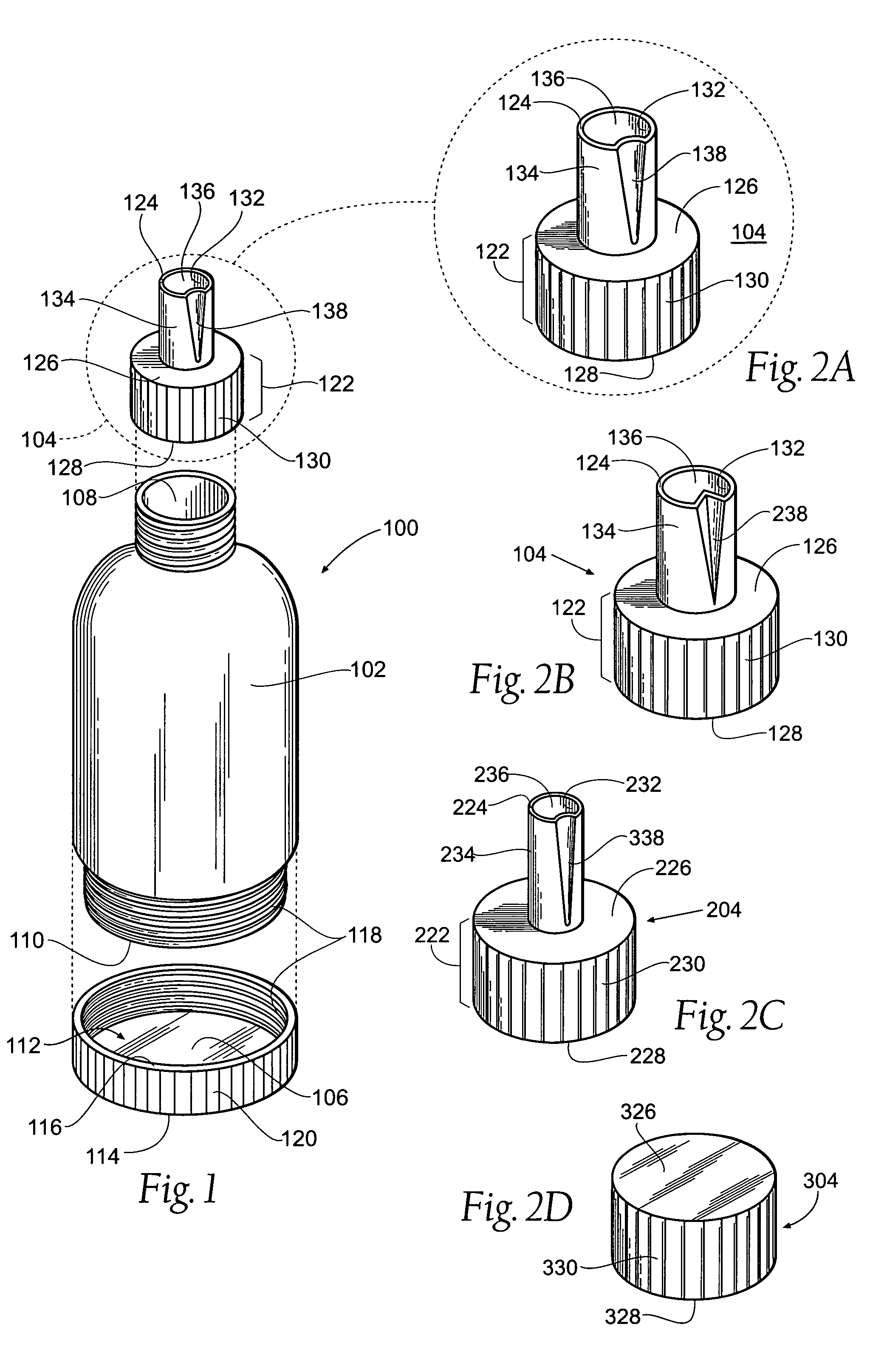

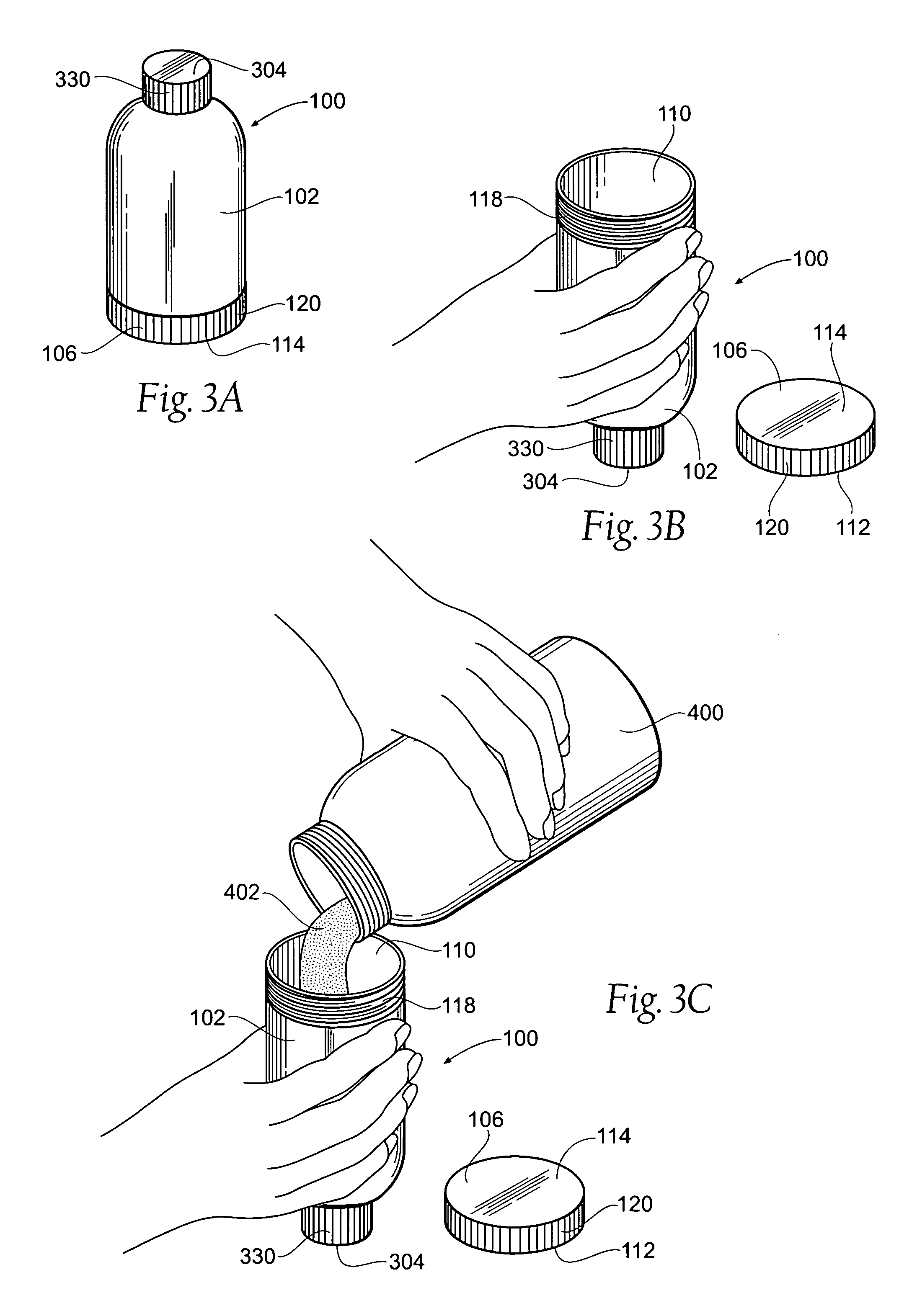

[0019]FIG. 1 shows an exploded view of an embodiment of the decanting device 100 according to the present invention. A preferred embodiment of the decanting device 100 preferably comprises a fluid reservoir 102, a cap 104, and a bottom lid 106. The fluid reservoir 102 has a top aperture 108 and a bottom aperture 110, although the present invention may be practical without the bottom aperture 110. The words ‘top’ and ‘bottom,’ as used herein, refer generally to different locations and no specific physical orientation is implied. Preferably, the reservoir 102 has a conventional cylindrical bottle shape, wherein the top aperture 108 is smaller than the bottom aperture 110. The reservoir 102 is preferably sized to comfortably fit in an average sized adult human hand. The reservoir 102 is preferably manufactured from a semi-rigid material, such as a semi-rigid plastic, so as to provide stability, as well as the ability to be squeezed by the human hand to thereby force a fluid out of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com