Modular portable compressor

a compressor and module technology, applied in the direction of positive displacement liquid engines, pump components, piston pumps, etc., can solve the problems of reducing assembly time, difficult and physically challenging mounting of many components directly on the compressor chassis or frame, and unnecessary physical strain or injury for assemblers, so as to reduce assembly time and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

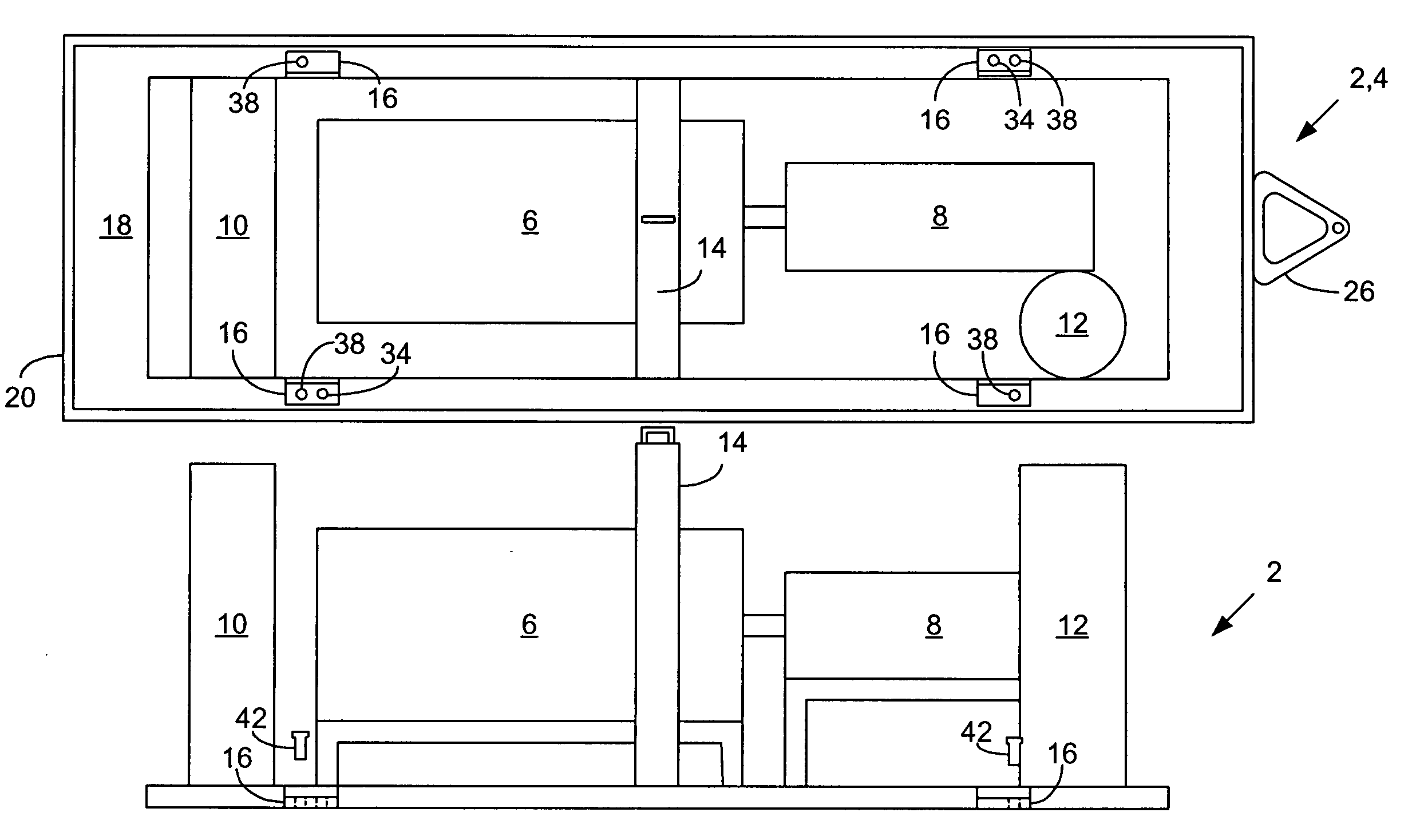

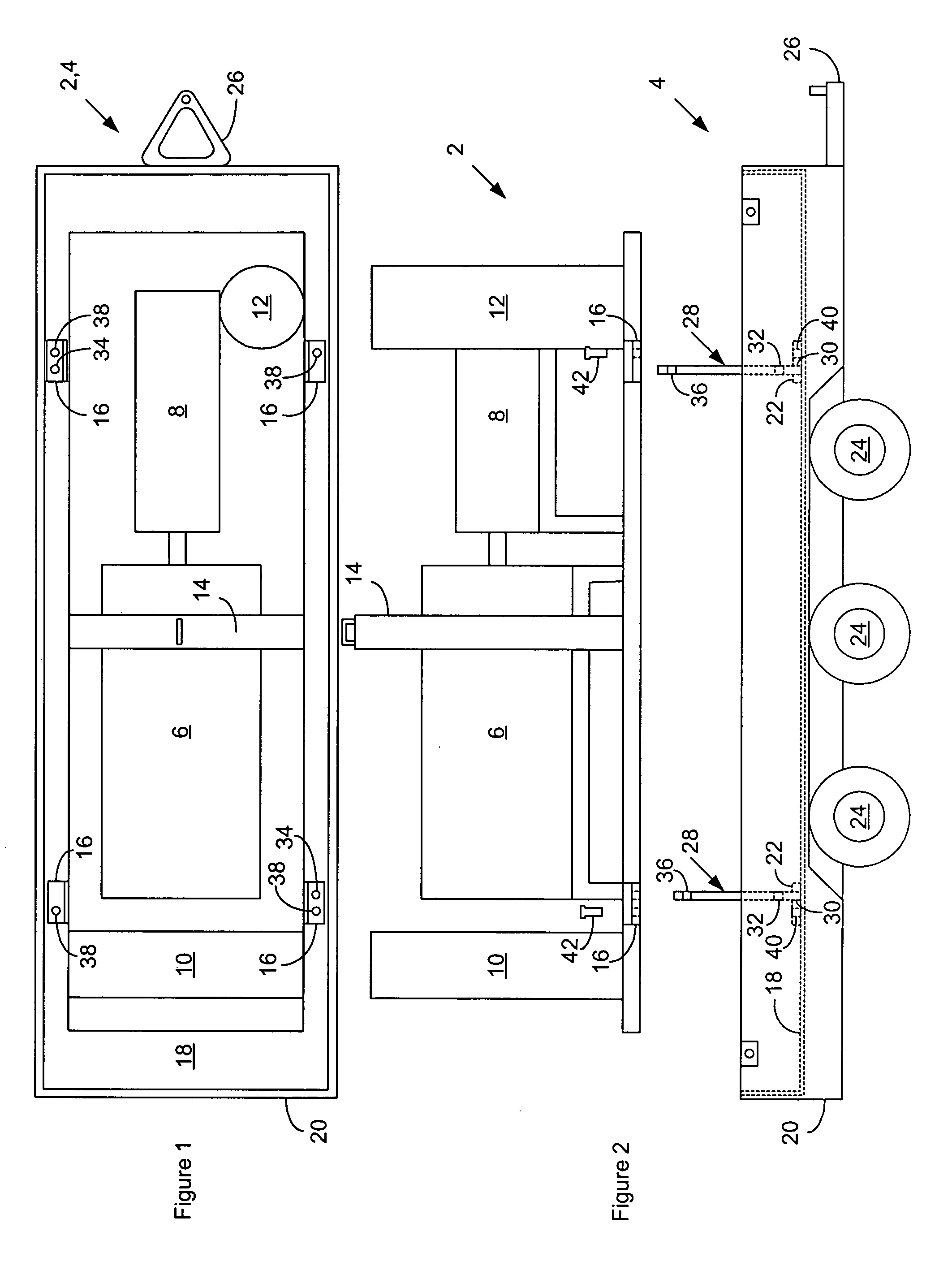

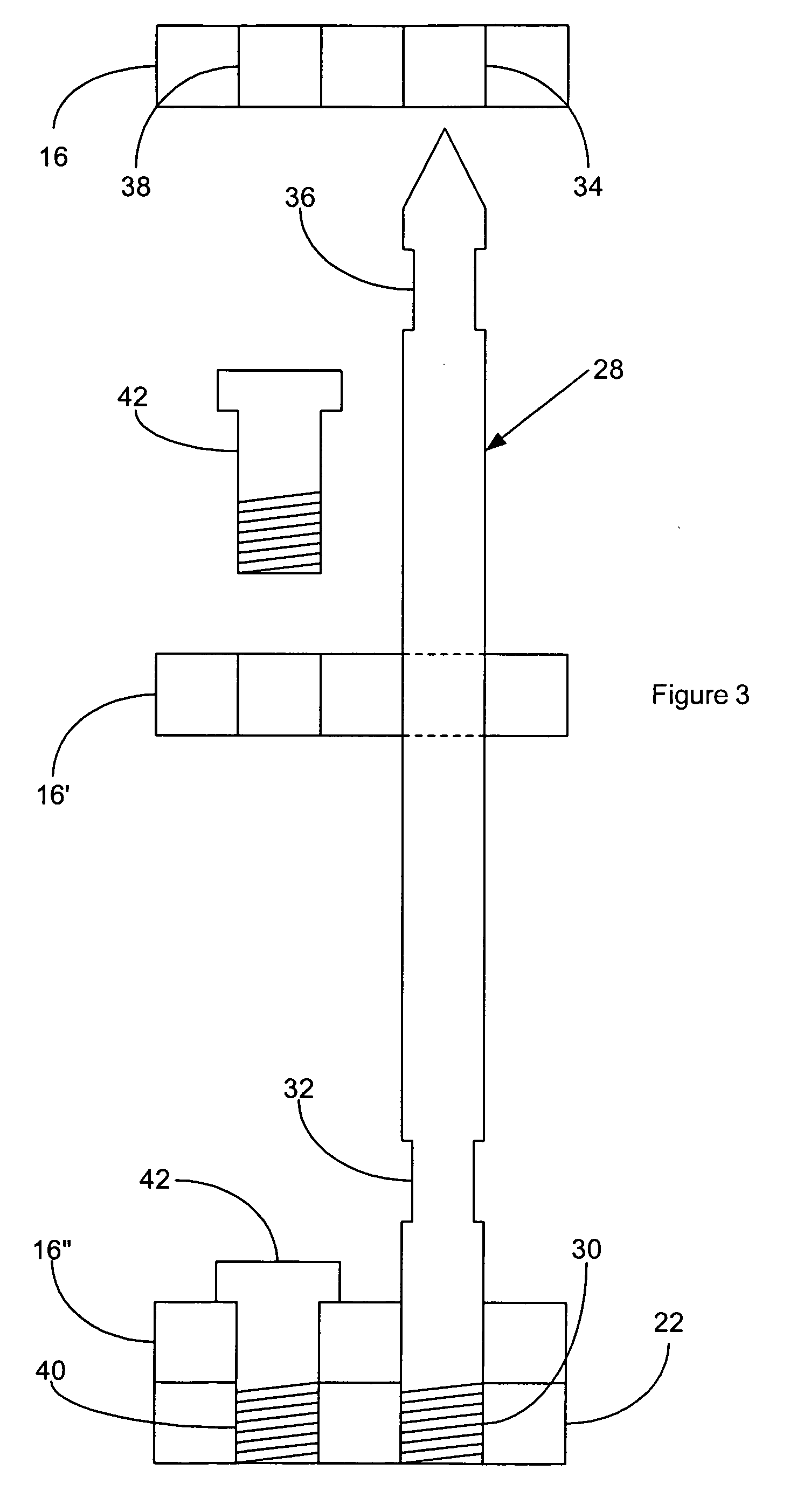

[0011]FIGS. 1 and 2 are top and side views, respectively, of a sub-frame module 2 ready to mount to a containment frame 4 module for a portable compressor according to a possible embodiment of the invention. The sub-frame module 2 preferably comprises a chassis for mounting most of the operating components for the compressor. These most commonly comprise a prime mover 6, typically a diesel engine, a compressor 8 coupled to the prime mover 6, an air cooling system 10, such as a cooler module, an accumulator 12, such as an air tank, a lifting bail 14. The sub-frame module 2 also mounts sundry components associated with the aforementioned components, such as batteries, hose lines, hydraulic tubing lines and so forth. Lastly, the sub-frame module 2 comprises a plurality of mounting pads or flanges 16 for mounting the sub-frame module 2 to the containment frame module 4.

[0012] It is convenient to mount the sub-frame module 2 on a movable platform, such as a scissor lift table, during as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com