Methods and apparatus for injecting atomized fluid

a technology of atomized fluid and method, which is applied in the direction of mechanical equipment, machines/engines, exhaust treatment electric control, etc., can solve the problems of affecting affecting the efficiency of atomizers, so as to reduce the emissions of oxides of nitrogen (nox) and enhance the performance of atomizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The ensuing detailed description provides exemplary embodiments only, and is not intended to limit the scope, applicability, or configuration of the invention. Rather, the ensuing detailed description of the exemplary embodiments will provide those skilled in the art with an enabling description for implementing an example embodiment of the invention. It should be understood that various changes may be made in the function and arrangement of elements without departing from the spirit and scope of the invention as set forth in the appended claims.

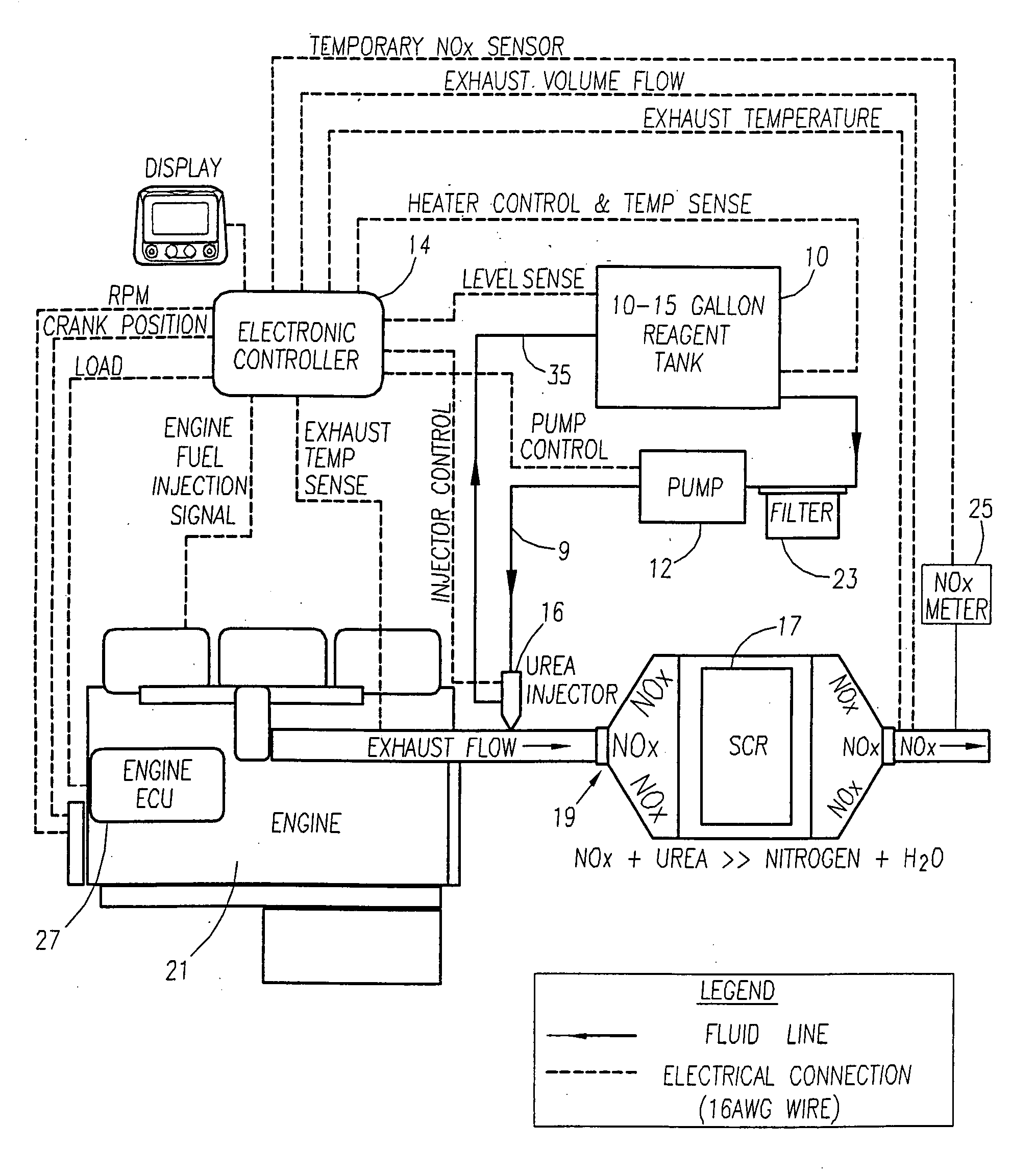

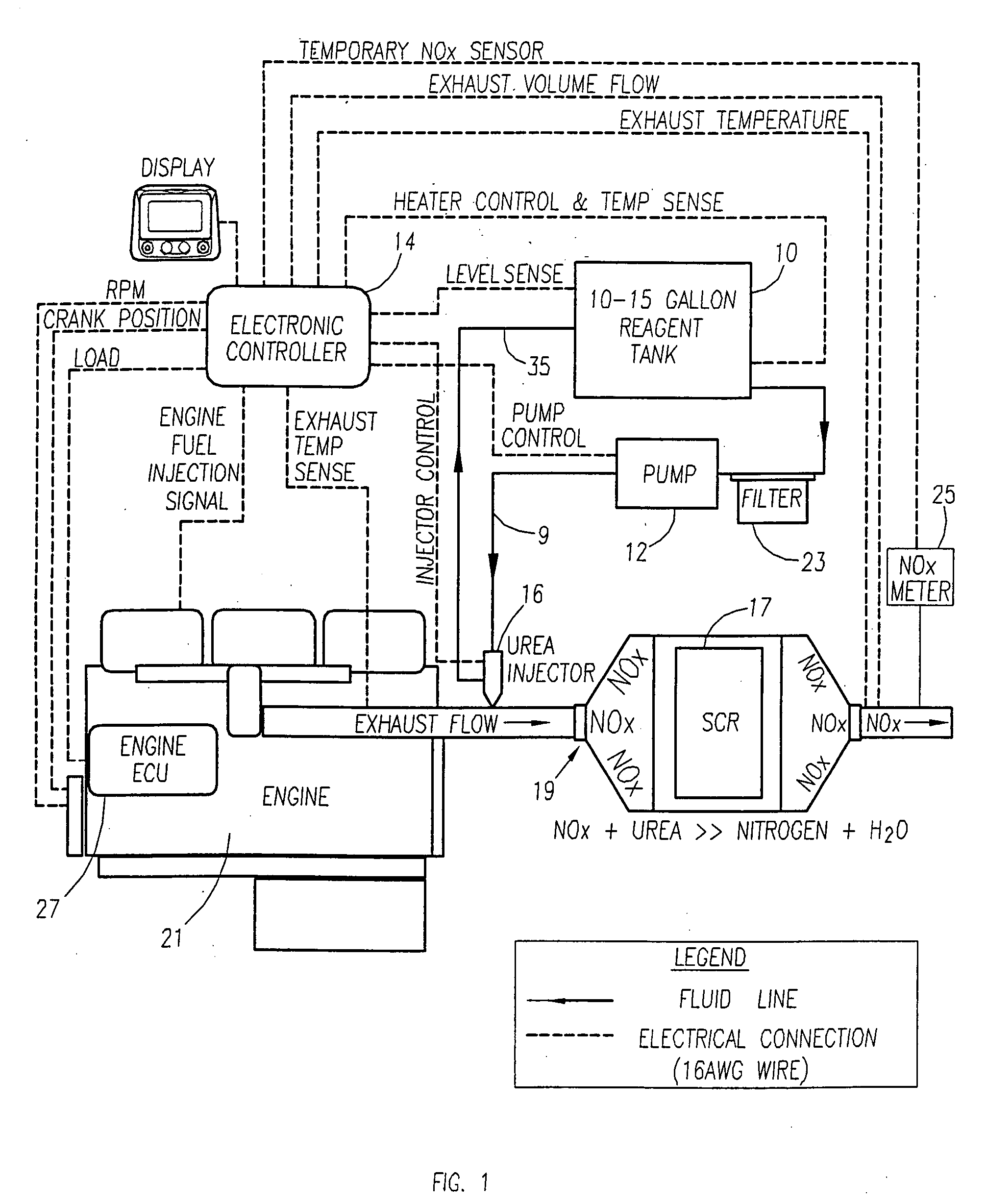

[0033]FIG. 1 shows an example pollution control system for reducing NOx emissions from the exhaust of a diesel engine 21. In FIG. 1, solid lines between the elements of the system denote fluid lines and dashed lines denote electrical connections. The system of the present invention may include reagent tank 10 for holding the reagent (e.g., aqueous urea) and a delivery module 12 for delivering the reagent from the tank 10. The tank 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com