Sour Natural Gas Pretreating Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

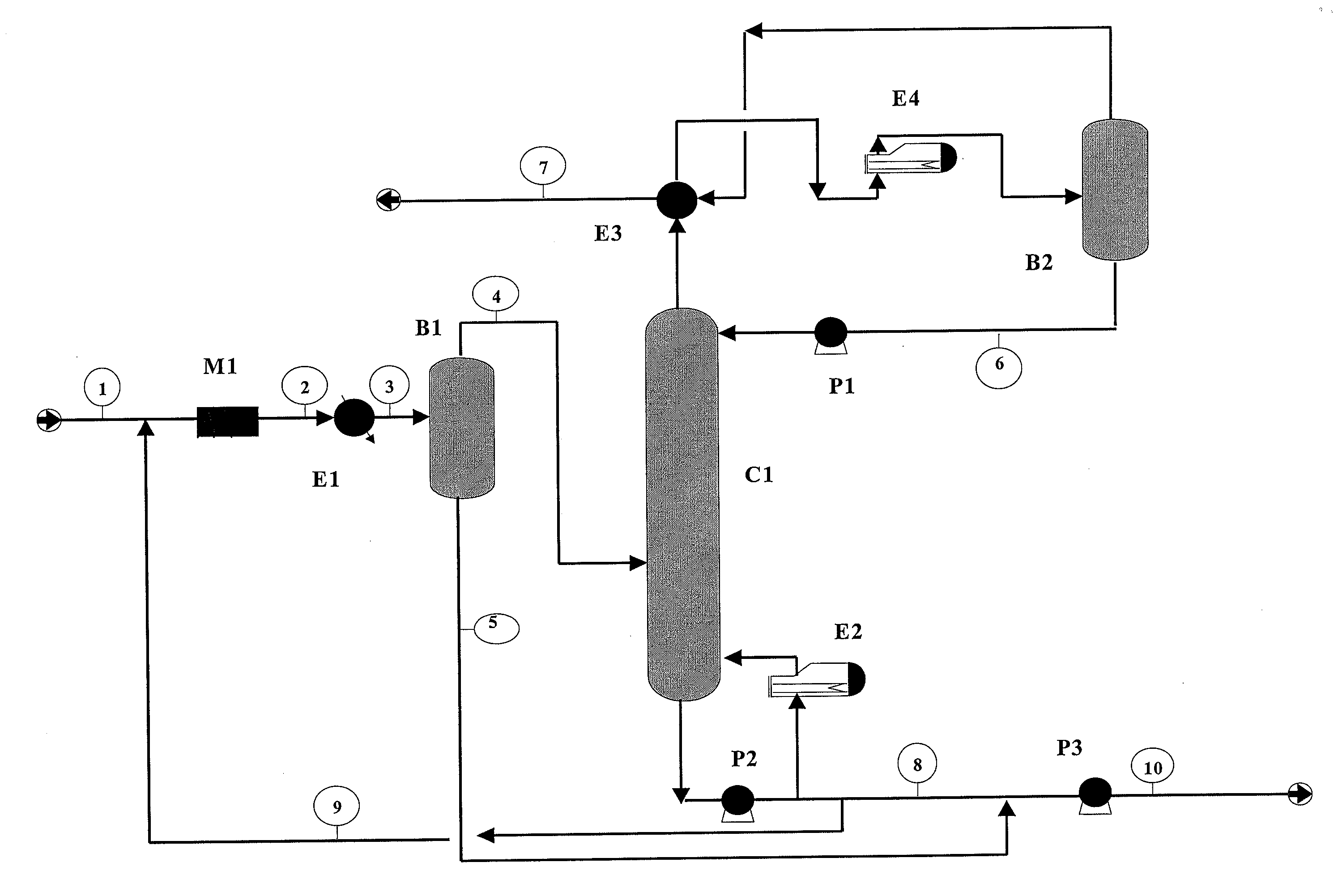

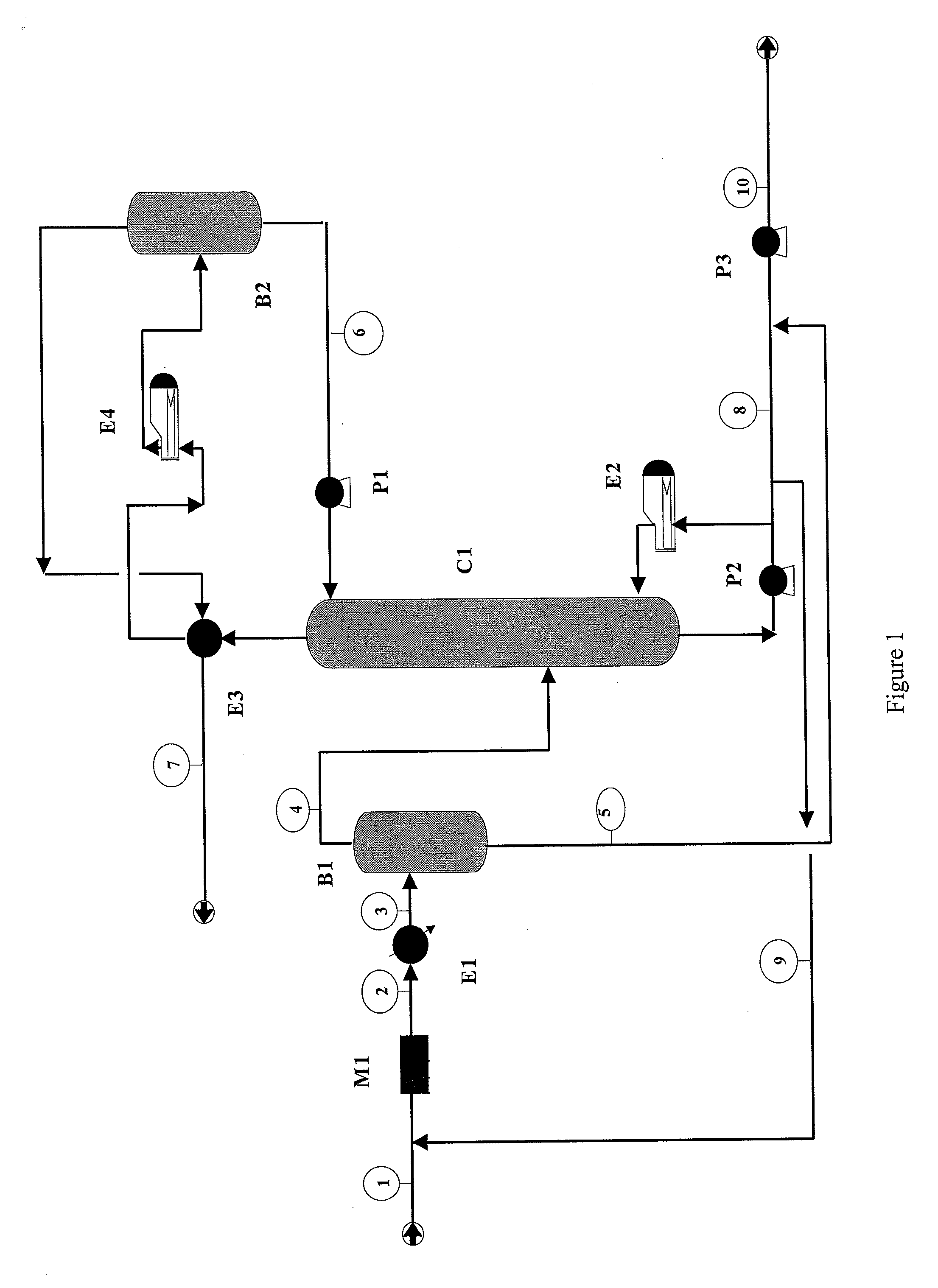

[0055] The process flowsheet described hereafter corresponds to FIG. 1. The compositions and the properties of the streams are numbered from 1 to 10 on the lines of the process flowsheet and they are defined in Table 1. The crude gas (1) is available at 30° C. and 62.3 bars. It contains approximately 18.8% by mole H2S and 1000 ppm by mole water. It is mixed with recycled stream (9). Injection of the H2S-rich liquid stream is carried out in the direction of flow of the stream through a branch line at the top of the line. The recycled stream is very rich in H2S (about 78% by mole), at a higher temperature than the crude gas because it directly comes from reboiler E2 of the column. A gas / liquid mixture (2) that is homogenized by passage through a mixer M1 is obtained.

[0056] At the outlet of mixer M1, the stream is heated up to 30° C. This stream is fed into separating drum B1. The gas phase (4) obtained is saturated with water, the excess water (5) condensing in drum B1. Gas phase (4)...

example 2

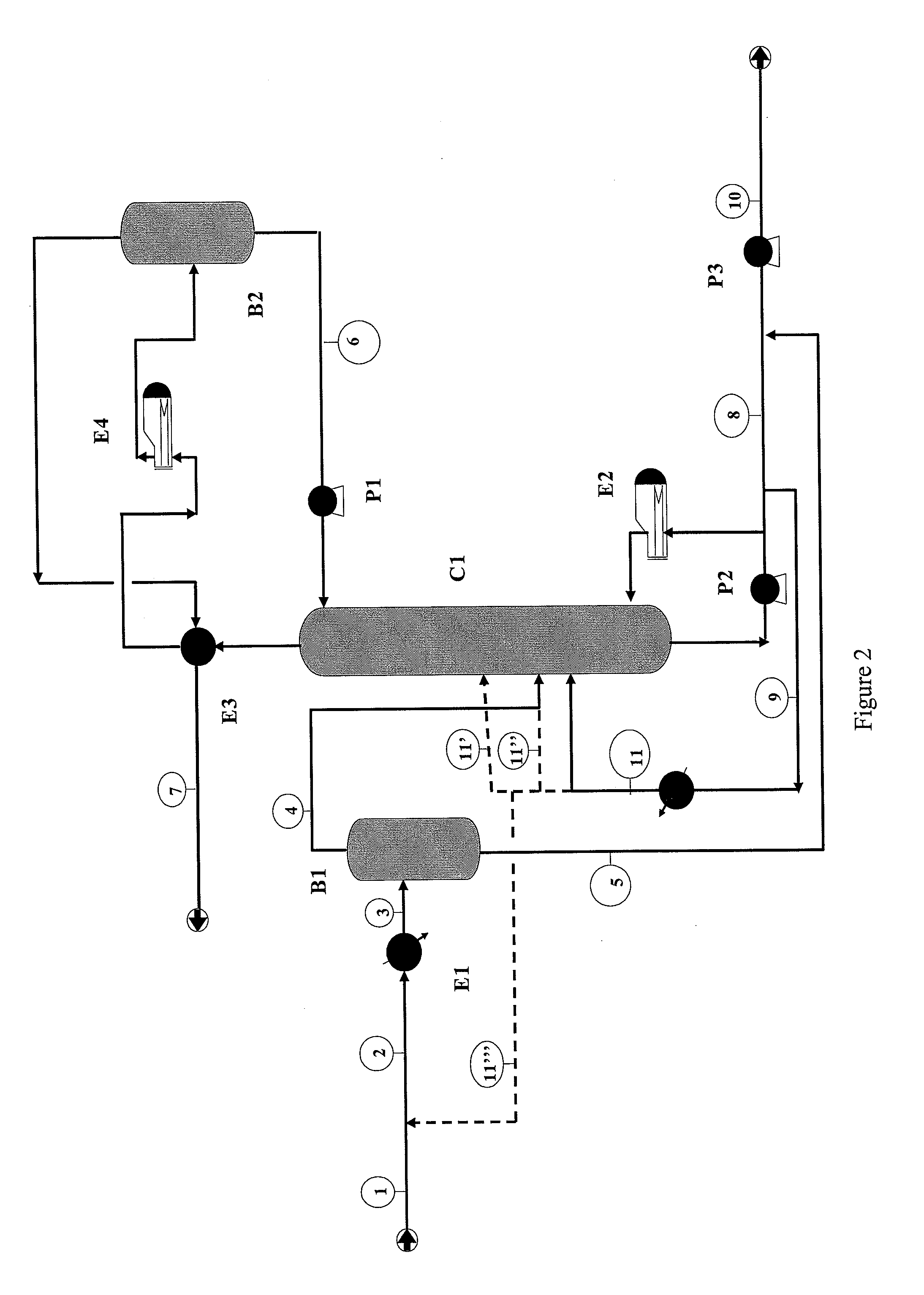

[0058] The process flowsheet described below corresponds to FIG. 2. The compositions and the properties of the streams are numbered from 1 to 11 on the lines of the process flowsheet and they are defined in Table 2.

[0059] In the diagram of FIG. 2, recycling (9) is achieved directly into separation column C1 with the stream bearing reference number (11). This recycling to the column is shown entering below gas feed point (4), but in other variants shown by dotted lines (11′), (11″), recycling can be achieved at any other level of the column, above or at the feed point. The stream directly fed into column (11) can represent all of or only part of recycled stream (9), and the other part (11′″) can be sent to gas intake (1) for example.

[0060]FIG. 2 illustrates the layout of a thermal exchanger E5 in relation to liquid recycled stream (9) from the column bottom. This exchanger allows the liquid to be more or less heated, to obtain either a gas / liquid mixture, or a gas at the dew point ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap