Hinged roof vent for attic

a roof vent and attic technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of increasing the temperature within the structure, leaking roof vents, and increasing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

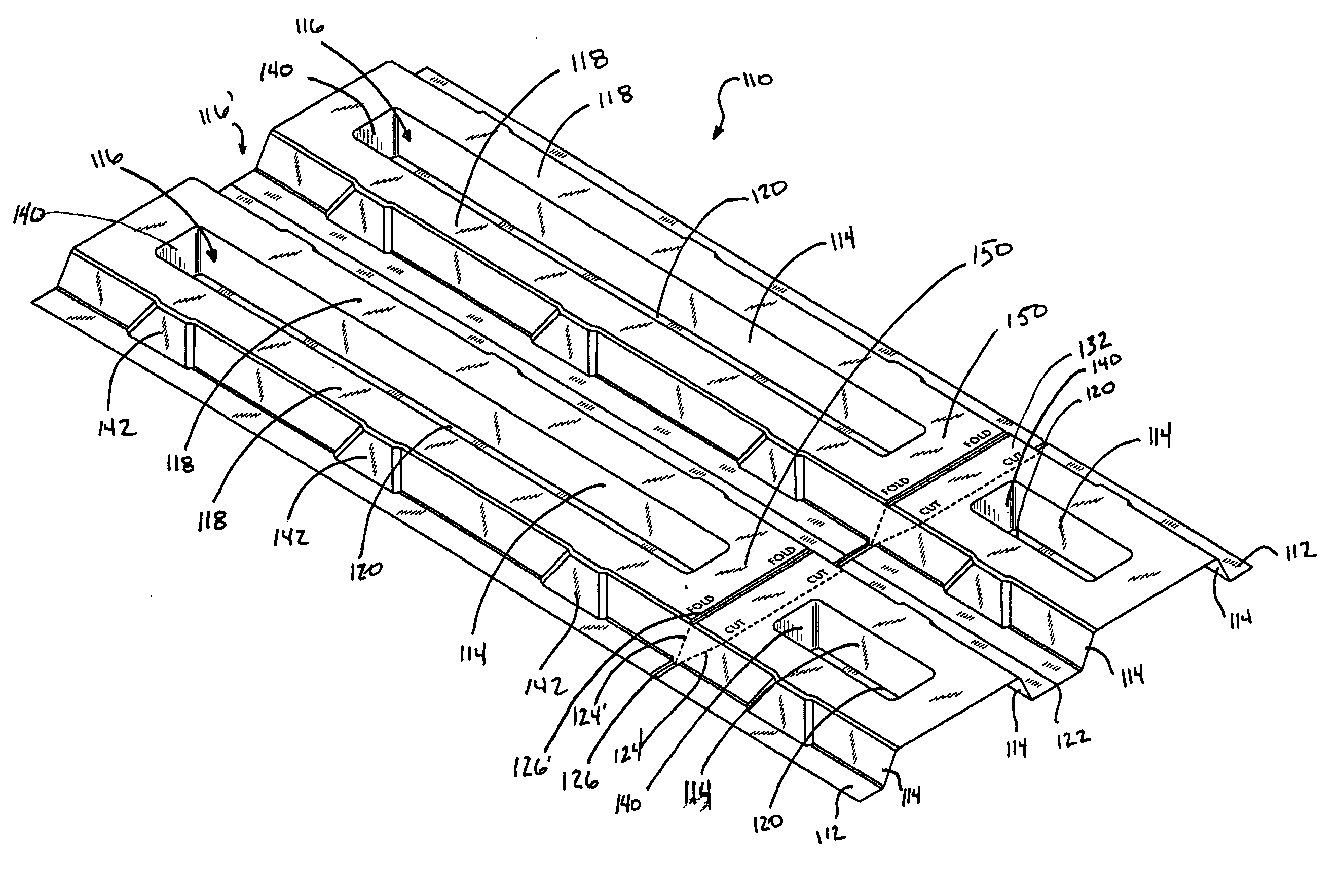

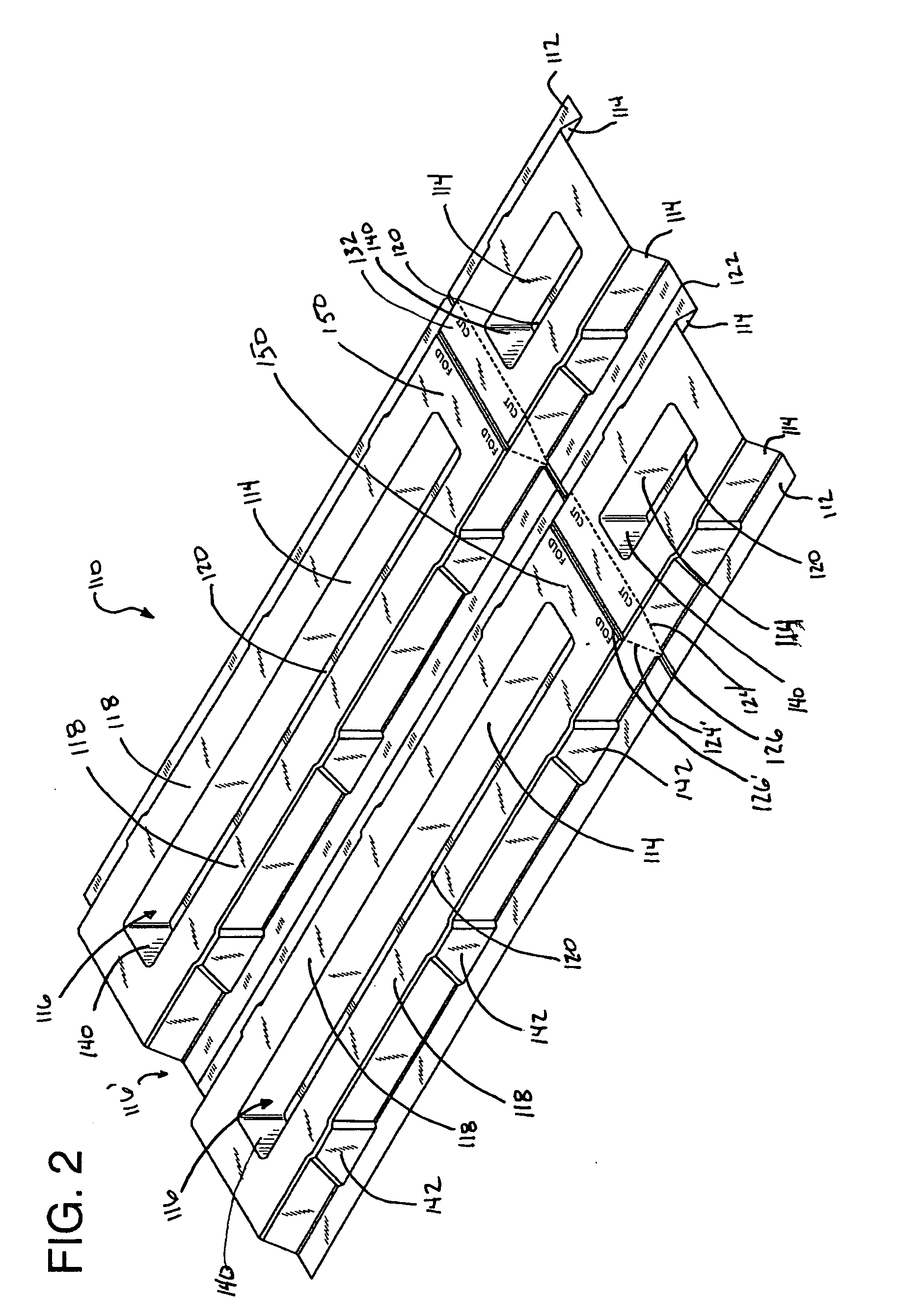

[0014] A hinged roof vent panel is provided which includes a combination of hinged ridges that allow the panel to be cut and folded to form an insulation block. The insulation block inhibits the flow of loosefill insulation which may block soffit vents and which provides suitable ventilation to inhibit condensation during cold periods and to allow acceptable airflow during warm periods. The vent panel may be thermoformed from a thin sheet of extruded polystyrene foam into the shape described and claimed herein. The panel is relatively planar and stackable so that a large number of panels may be packaged together for shipping.

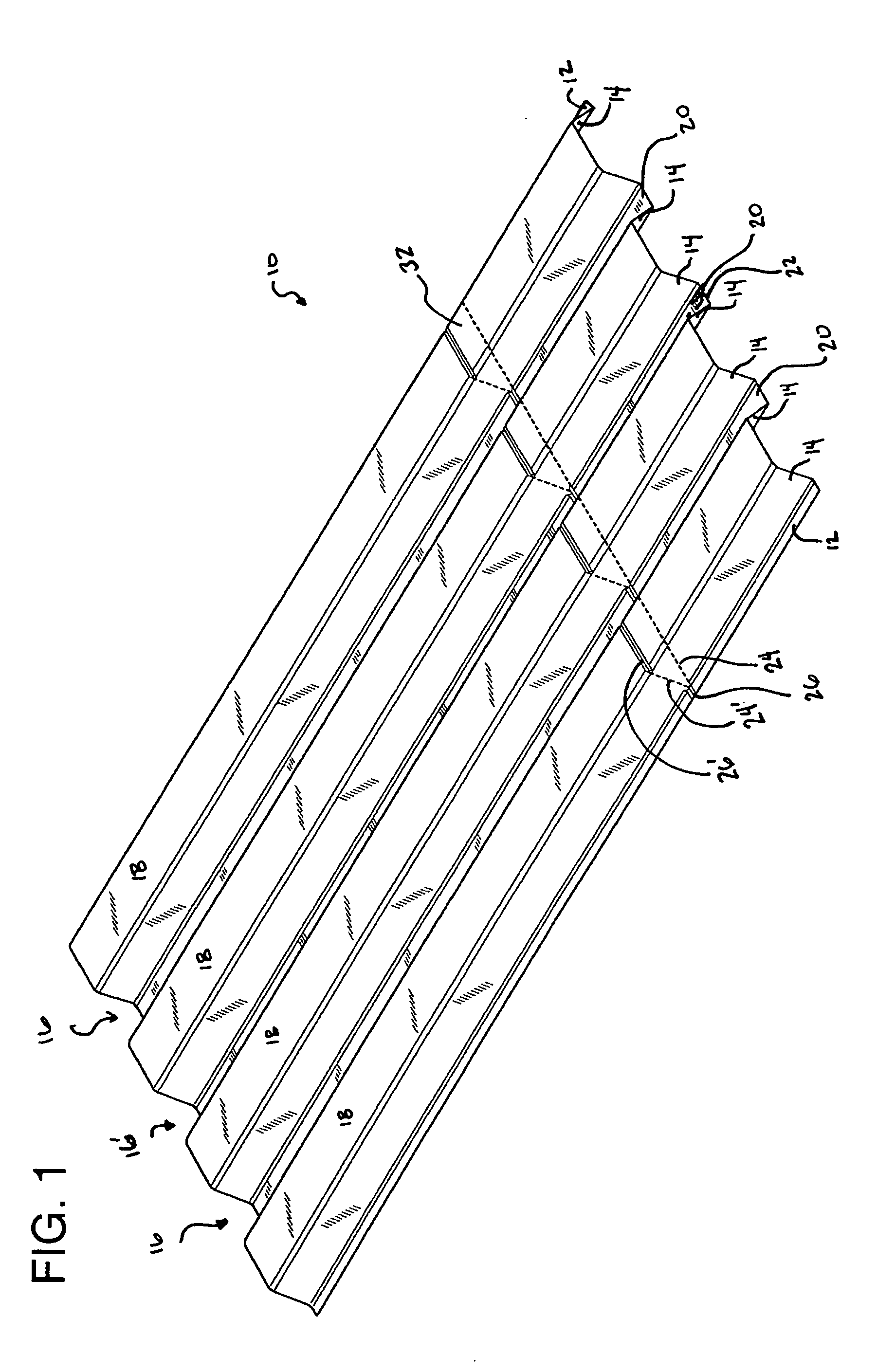

[0015] As shown in FIG. 1, a hinged roof vent panel 10 in accordance with one embodiment of the present invention is formed with edge flanges 12 and sloping lateral walls 14 which extend upwardly to offset insulation blocking segments 18 that are positioned parallel to but raised from flanges 12 and bases 20 of trapezoidal ridges 16 and 16′. Next to the offset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com