Device for wrapping a bale of pasture or the like

a technology for wrapping bales and pastures, applied in the field of wrapping devices, can solve the problems of dragging nets or the like into the baling chamber, affecting the quality of pastures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

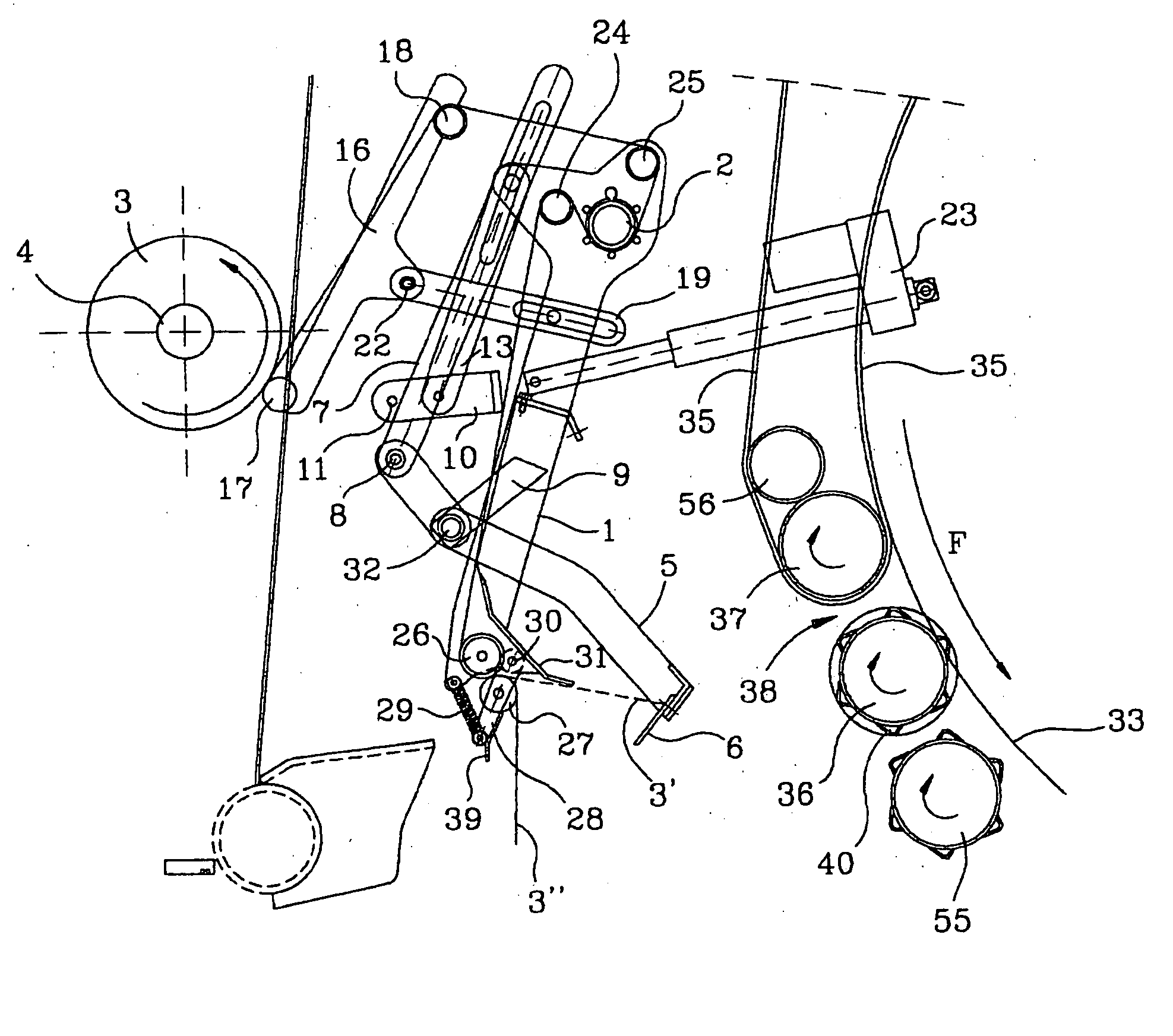

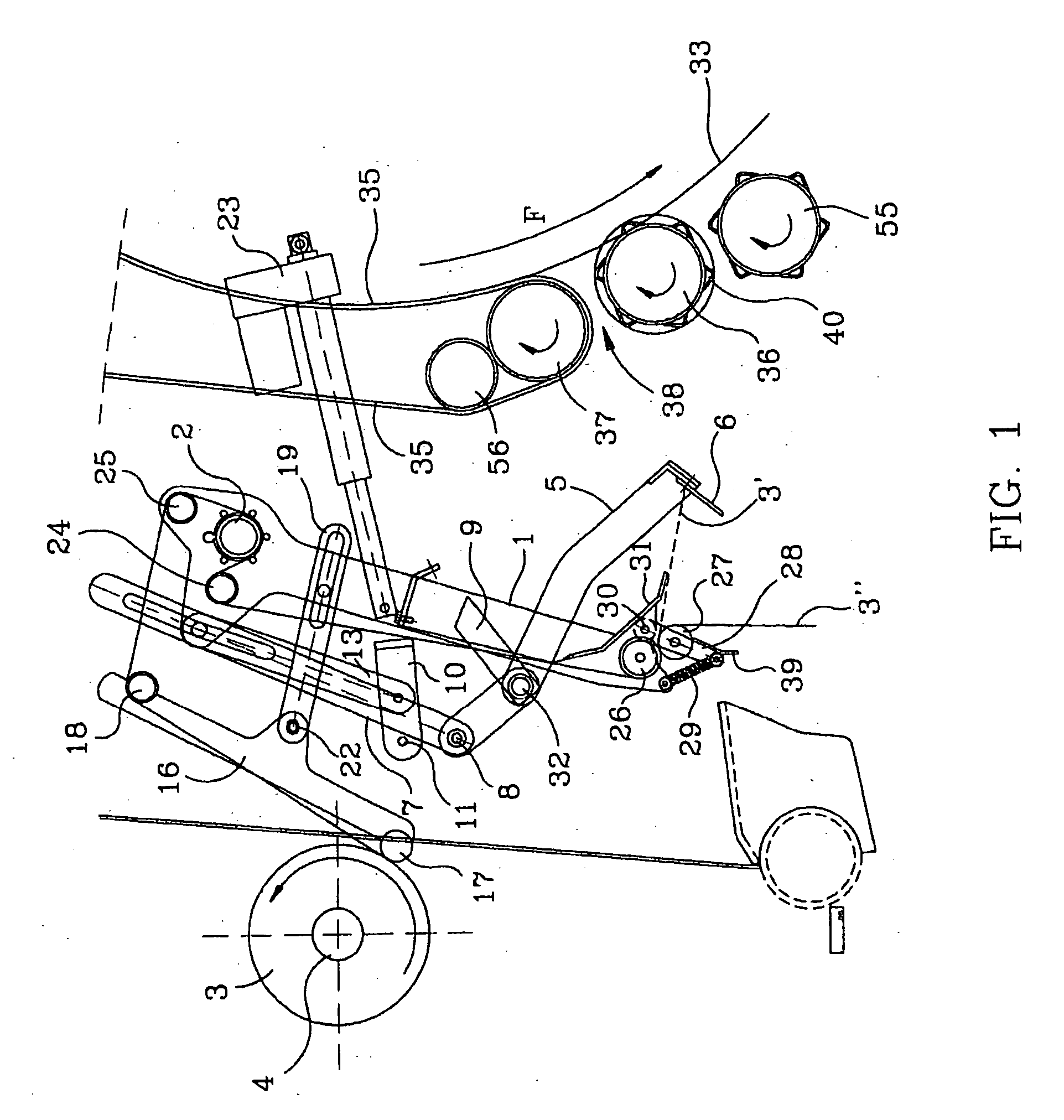

[0032] Referring first to FIG. 1, this figure shows the wrapping device of the invention in the rest position. This figure is very schematic, and it only shows those parts which are necessary to understand the invention, whereas the remaining parts (which are standard in round balers) will be omitted altogether for simplicity since the skilled person is already aware of their existence. The wrapping device first includes a dispensing device 1, taking the form of a rocker lever, and including two arms that are pivotly mounted around the axis 2. In reality, the two arms of the rocker lever 1 may swivel around the outer side of two respective rings which are fixed to the respective opposite inner side walls of the round baler. On the inner part of these rings there are provided bearings for a transversal shaft 2, which extends between the rings, said transversal shaft being idly mounted in order to permit the advancement of the net.

[0033] Moreover, the wrapping device comprises a “res...

second embodiment

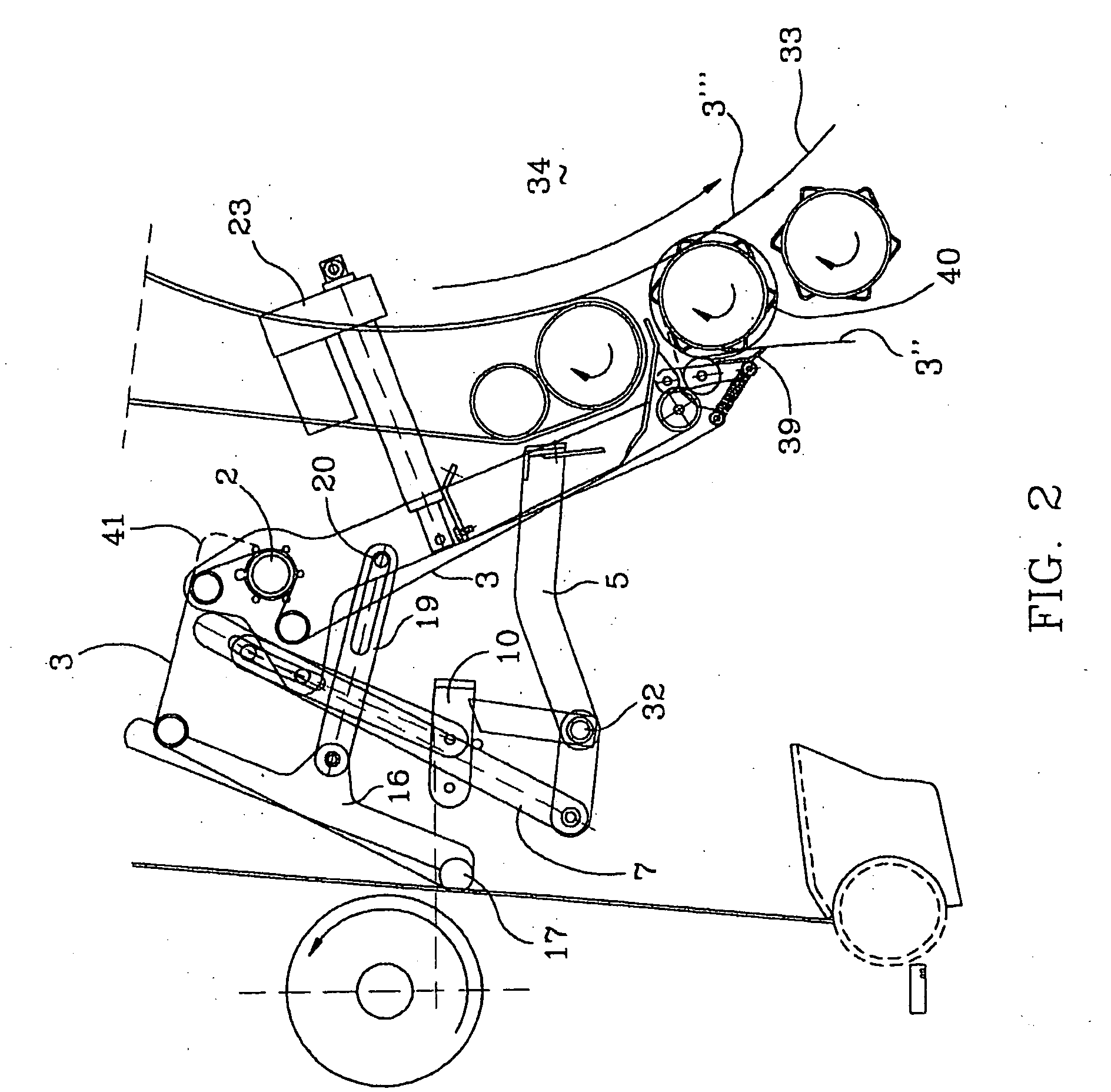

[0055] With reference to FIGS. 4, 5, 6 and 7, we will now describe the present invention.

[0056] This second embodiment differs from the first only in some features, so that the same reference numbers will be maintained as much as possible, except (obviously) for components that have no identical counterpart.

[0057] Nor will it be necessary to repeat the preceding description for identical parts that are already contained in the first embodiment.

[0058] In this second embodiment, the lower part of the rocker lever 1 differs from the first embodiment in that besides the two rollers 26, 27—in the present case denoted by 26′, 27′—there is provided a third roller 42. Moreover, the roller 42 is idly mounted on a second lever 43 which is pivoted on the respective arm of the rocker lever 1, while a spring 44 (one for each arm of 1) connects the free end of the lever 43 to the free end of the lever 28′. The net 3 extends along a zigzag path between the three idle rollers 26′, 27′, 42. Howeve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com