Through-hull connector for boats

a technology for connecting parts and boats, applied in the direction of hulls, vessel construction, pipes, etc., can solve the problems of nut expansion under hoop stress, female threads slipping over the male threads, and one mode of failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

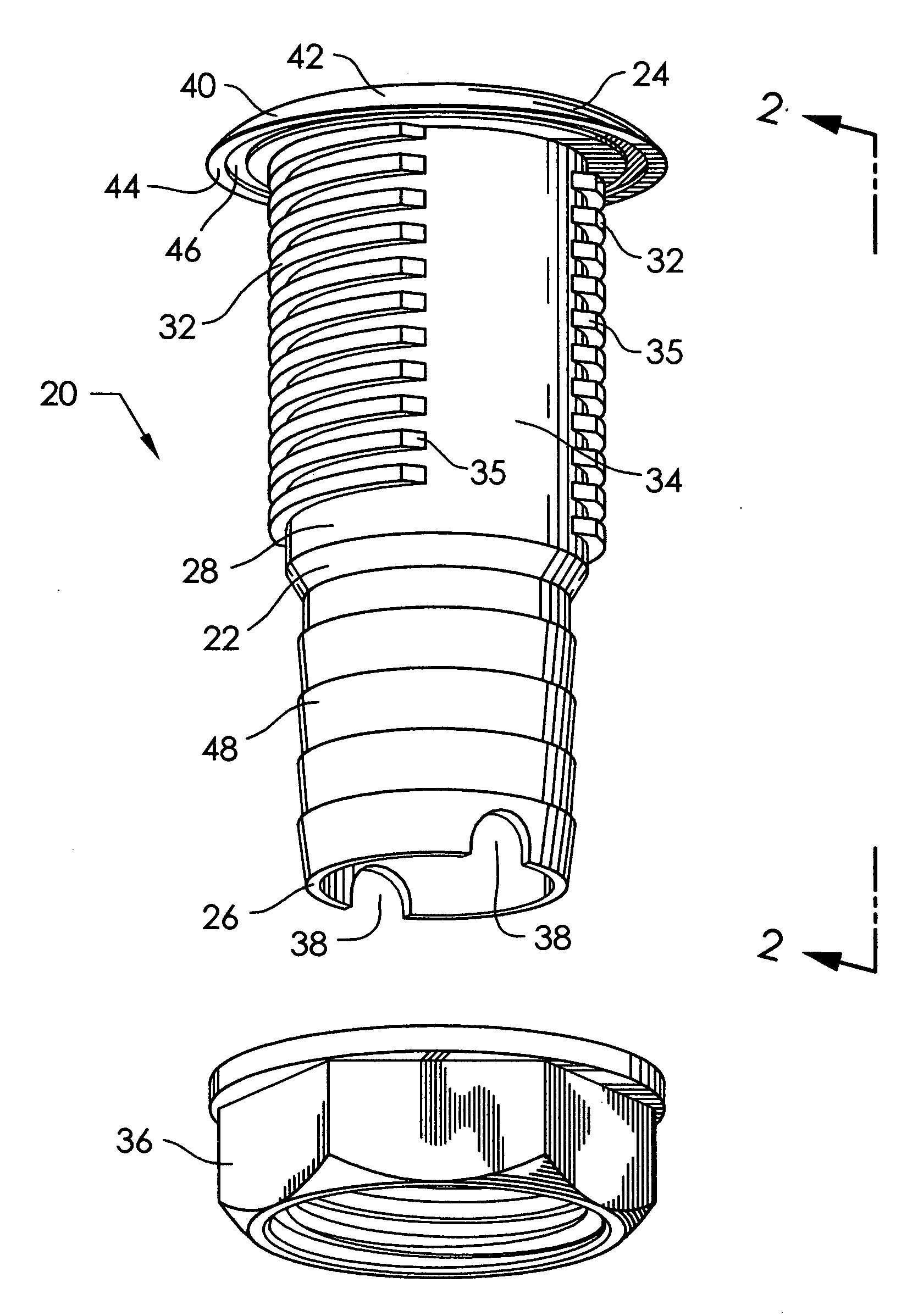

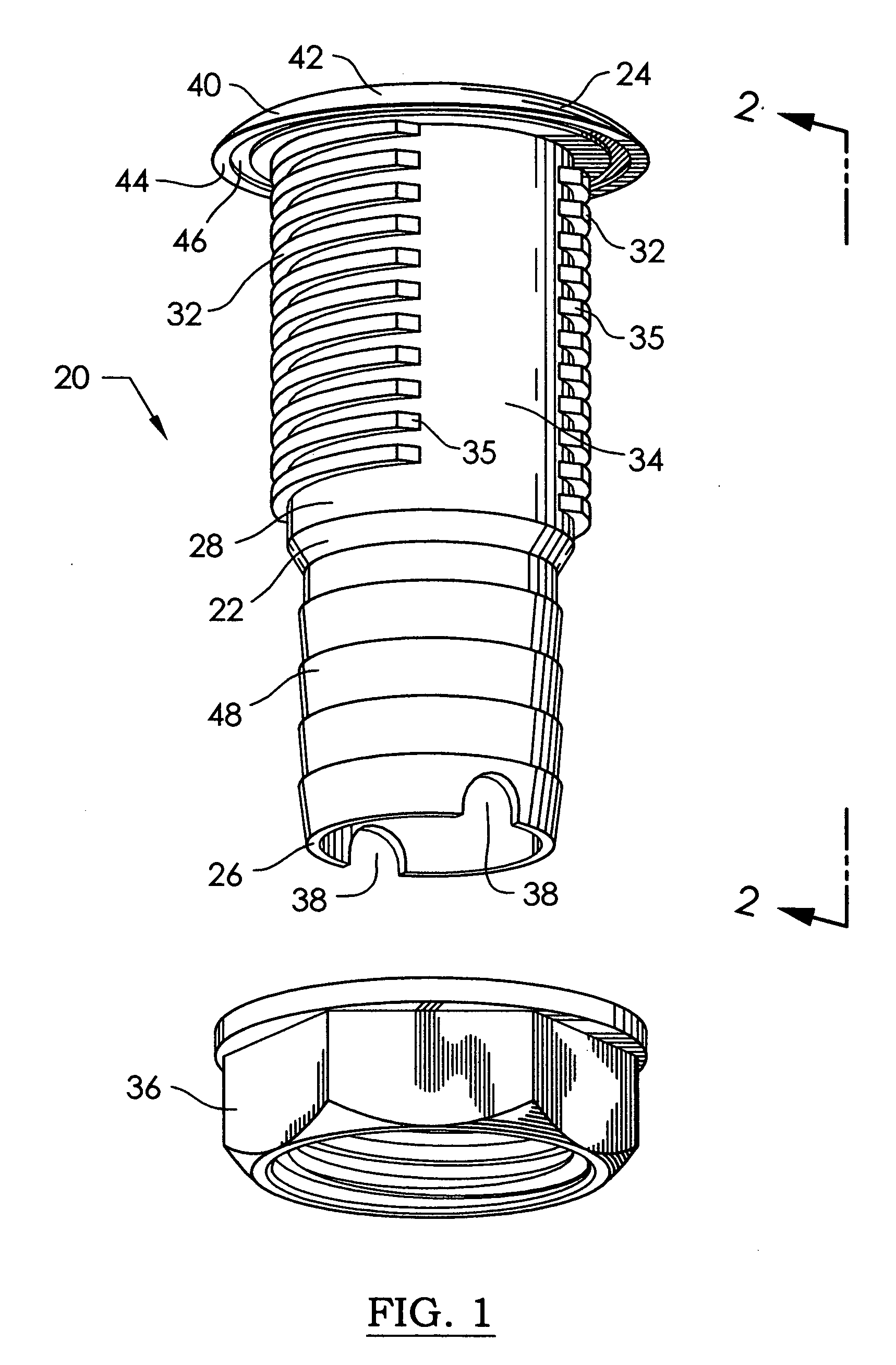

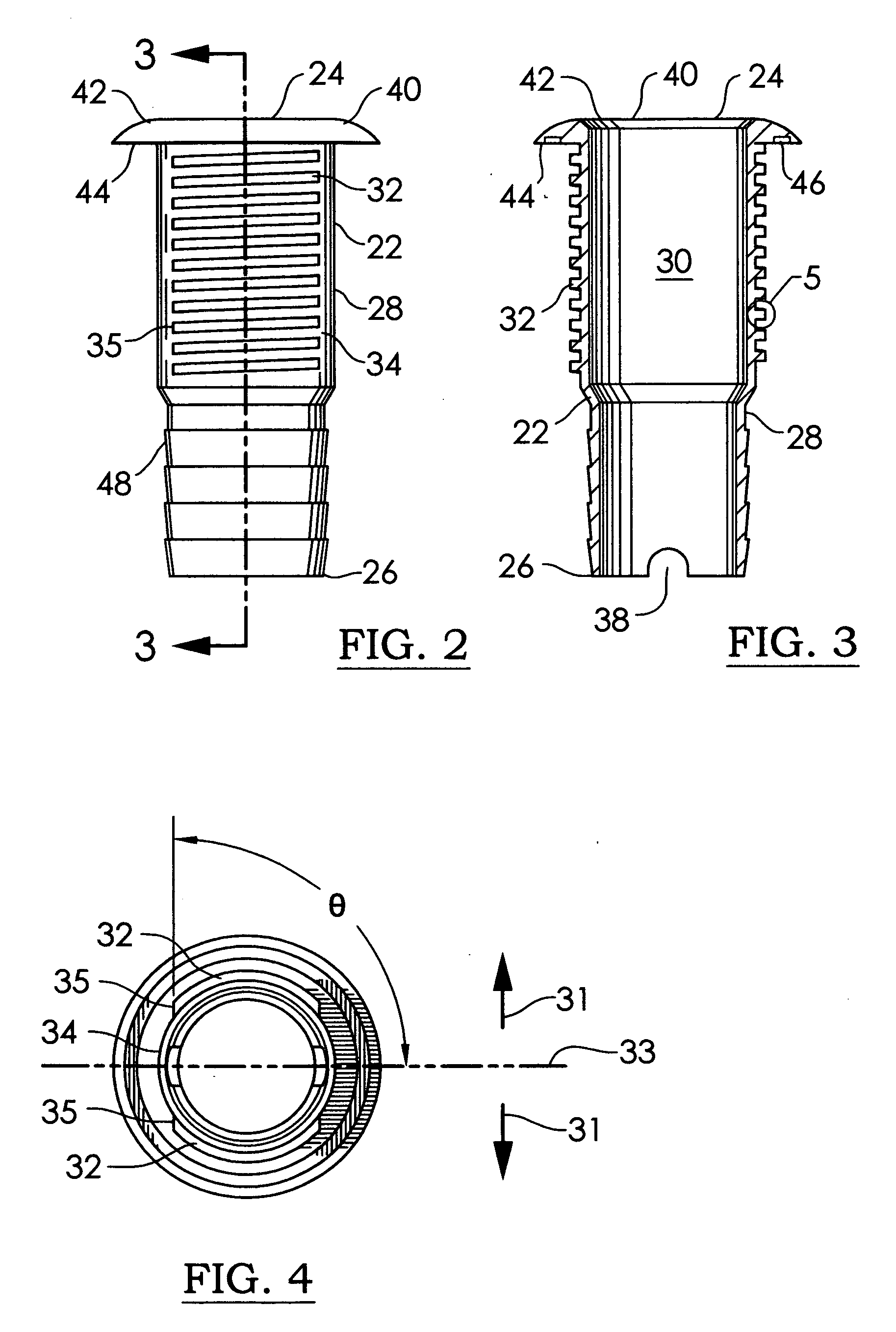

[0034] Referring now to the drawing, and especially to FIGS. 1-6 thereof, a through-hull connector is shown at 20, and is for use in connection with a hull of a boat (not shown), the hull having an outer surface and an inner surface. The through-hull connector 20 comprises a body 22 extending between opposite first 24 and second 26 ends, and having a central axis. The body 22 has a circular cross-section, an outside surface 28 and a bore 30 through the body 22 from the first end 24 to the second end 26. Threaded fastening means is provided for fastening the through-hull connector 20 to the boat hull. The fastening means has external threads 32 with a generally quadrilateral cross-section, as shown in FIG. 5a as a sharp-edged square thread 32a. FIG. 5b shows the same square thread with radiused edges 32b. FIG. 5c illustrates an embodiment known as an acme thread 32c. FIG. 5d depicts yet another embodiment, this being a buttress thread 32d. While not explicitly rectangular, the acme 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com