Flocked cosmetic applicators

a cosmetic applicator and applicator technology, applied in the field of topical applicators, can solve the problems of not having the same soft feel as the foam tipped applicator, the applicator is not as durable as might be desired, and the foam is a relatively expensive element for use in the cosmetic applicator, so as to reduce the cross-sectional area, reduce the cost, and soften the consumer's fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

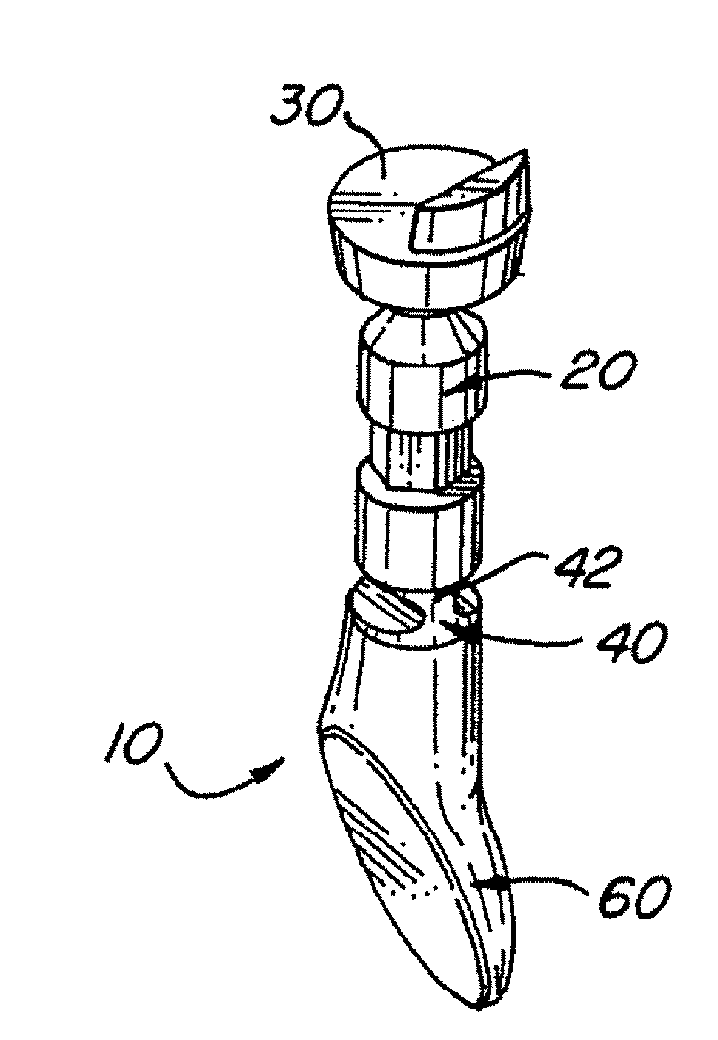

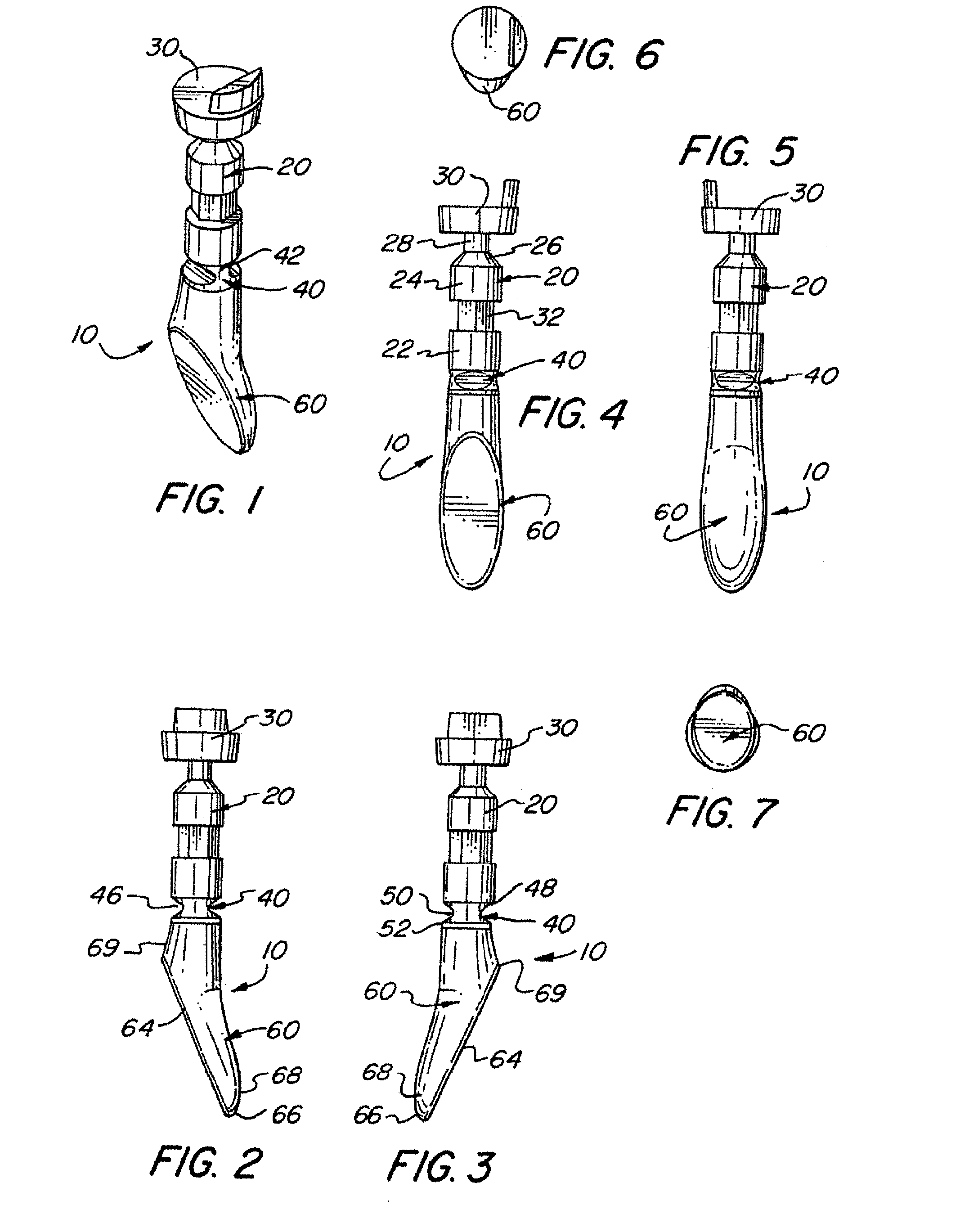

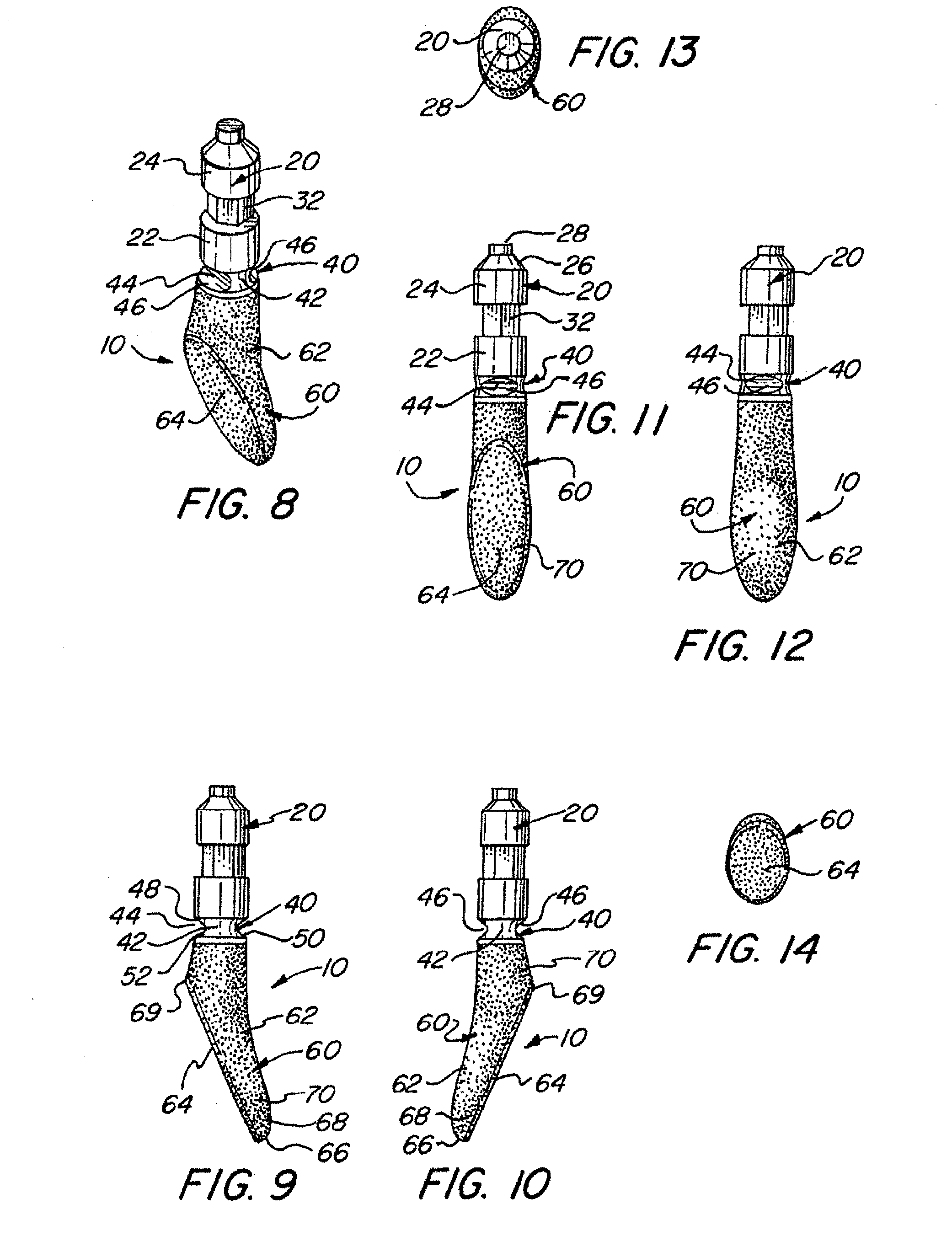

[0060]Referring now to FIGS. 1-14, a cosmetic applicator 10 in accordance with the invention is shown. In FIGS. 1-7, cosmetic applicator 10 is shown as initially molded; in FIGS. 8-14, the same cosmetic applicator 10 is shown with the umbrella element 30 removed and flocking 70 applied. Cosmetic applicator 10, as shown in FIGS. 1-14, comprises an upper mounting element 20, a flexing element 40, and an applicator tip 60. Cosmetic applicator 10 is molded from LDPE, HDPE, polyester, polypropylene or other suitable plastic material, and in preferred embodiments is formed of HYTREL® polyester, HDPE or LDPE.

[0061]Upper mounting element 20 includes a lower endpiece 22 having a lower endpiece cross-sectional area, and an upper endpiece 24 having an upper endpiece cross-sectional area. Lower endpiece 22 and upper endpiece 24 are preferably generally cylindrical in shape. The upper endpiece 24 preferably has an upper conical section 26 tapering to a rod 28. Rod 28, as seen in FIGS. 1-7, is pr...

second embodiment

[0068]Referring now to FIGS. 15-28 a cosmetic applicator 210 in accordance with the invention is shown. In FIGS. 15-21, cosmetic applicator 210 is shown as initially molded; in FIGS. 22-28, the same cosmetic applicator 210 is shown with the umbrella element 230 removed and flocking 270 applied. Cosmetic applicator 210, as shown in FIGS. 15-28, comprises an upper mounting element 220, a flexing element 240, and an applicator tip 260.

[0069]Upper mounting element 220 includes a lower endpiece 222 having a lower endpiece cross-sectional area, and an upper endpiece 224 having an upper endpiece cross-sectional area. Lower endpiece 222 and upper endpiece 224 are preferably generally cylindrical in shape. The upper endpiece 224 preferably had an upper conical section 226 tapering to a rod 228. Rod 228, as seen in FIGS. 15-21, is provided with an umbrella element 230, which is removed after molding of the cosmetic applicator, leaving a shortened rod 228 as seen in FIGS. 22-28. A stem 232 con...

third embodiment

[0073]Referring now to FIGS. 29-40, a cosmetic applicator 310 in accordance with the invention is shown. In FIGS. 29-34, cosmetic applicator 310 is shown as initially molded; in FIGS. 35-40, the same cosmetic applicator 310 is shown with the umbrella element 330 removed and flocking 370 applied. Cosmetic applicator 310, as shown in FIGS. 29-40, comprises an upper mounting element 320, a flexing element 340, and an applicator tip 360.

[0074]As previously described in connection with the first and second embodiments of FIGS. 1-28, upper mounting element 320 includes a lower endpiece 322 connected by a stem 332 to an upper endpiece 324, which connects to a rod 328 and umbrella element 330.

[0075]A flexing element 340 connects the upper mounting element 320 to the applicator tip 260. The flexing element 340 has a portion 342 having a lesser cross-sectional area than the adjacent lower endpiece 322 of the upper mounting element 320 defined by the existence of at least one partially cutaway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com