Scaffold Support Bracket and Assembly

a technology of support brackets and supports, which is applied in the direction of scaffold connections, building scaffolds, building aids, etc., can solve the problems of inability to allow the brace, lack of flexibility in the connection of two members together, etc., and achieves the effects of low cost, low manufacturing cost and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

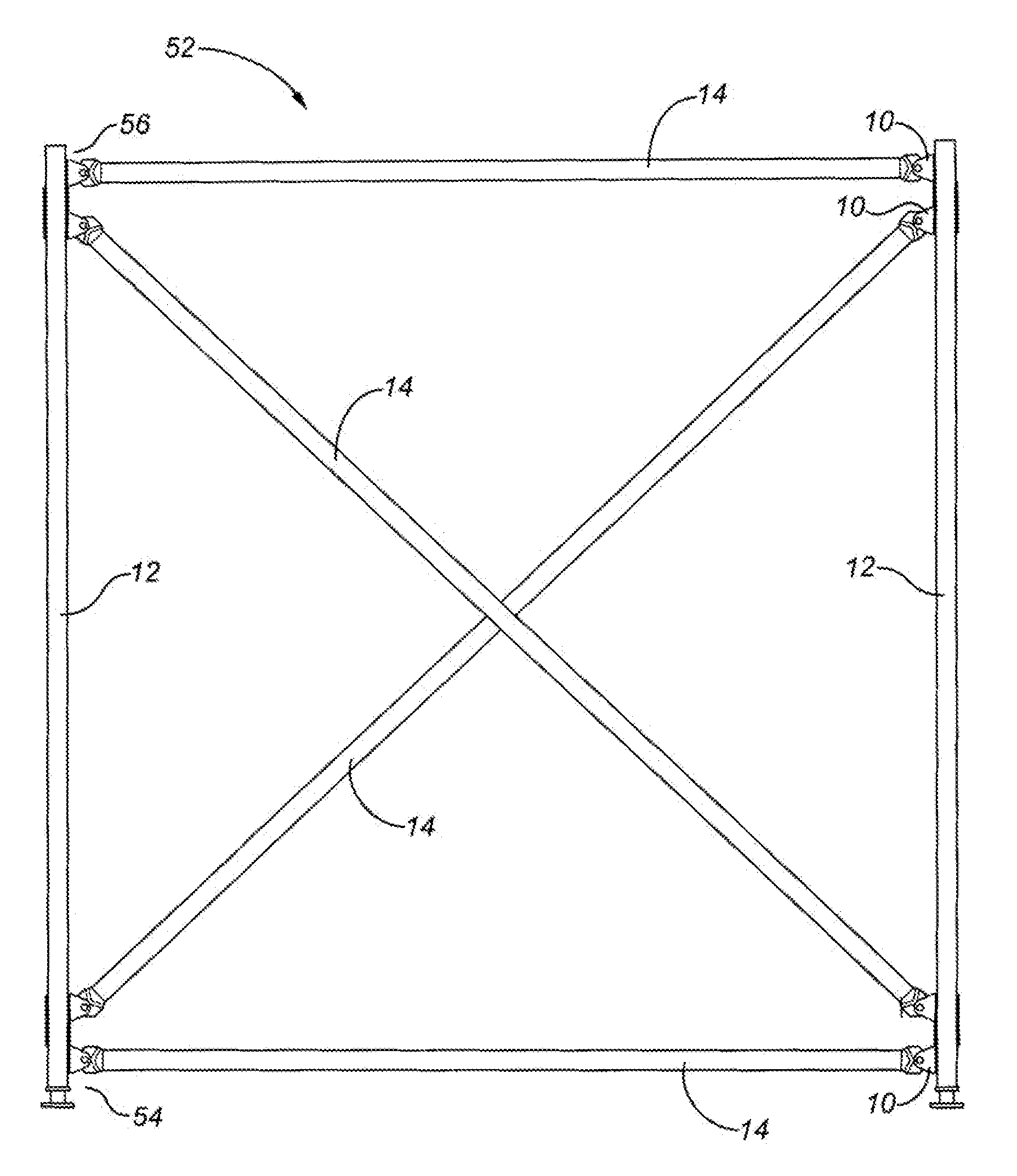

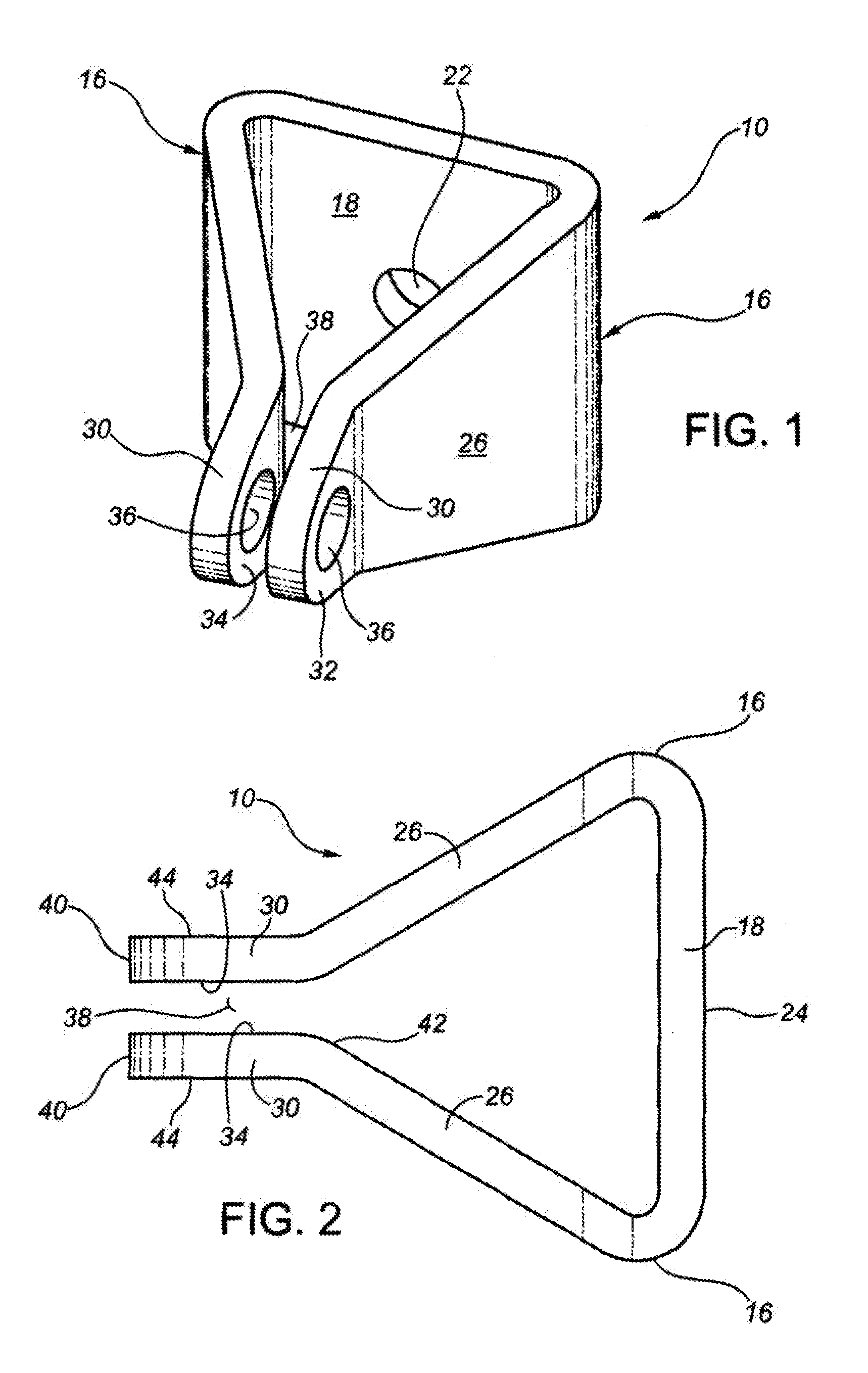

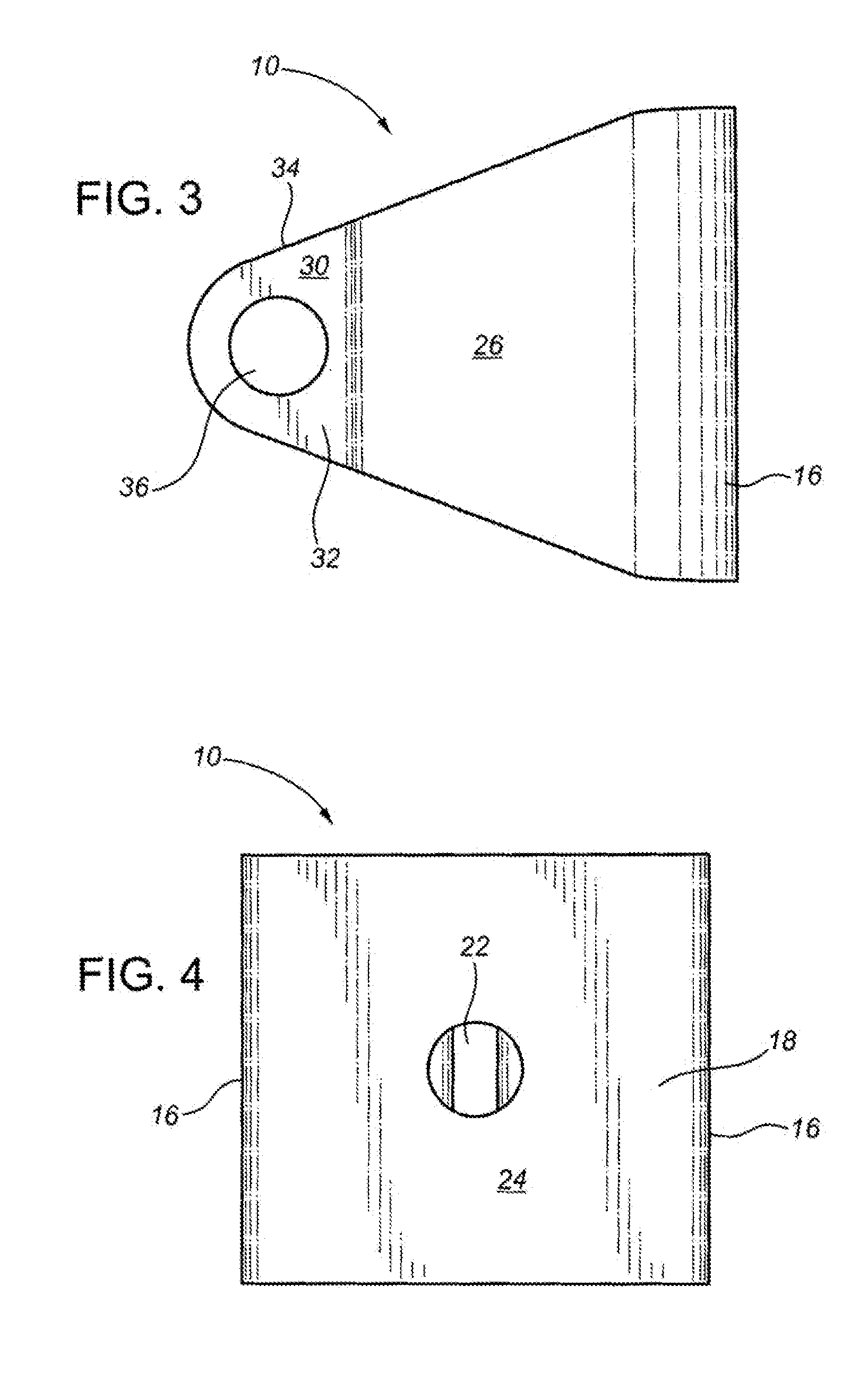

[0038] Referring to FIGS. 1 to 4, scaffold support bracket 10 is shown connecting a cross member to a vertical support tube to form a scaffold assembly. Bracket 10 comprises base member 18 at rear portion 20. Base member 18 comprises opposing sides 16 and is substantially vertical and planar and can be generally rectangular in structure. Aperture 22 is formed on base member 18 and extends therethrough. Aperture 22 is configured to receive a first fastener (not shown) therein for attachment to vertical support tube 12. Base member 18 has rear surface 24 that contacts and mates to the exterior surface of a vertical support tube as described in further detail below.

[0039] Base member 18 comprises a pair of arms 26 that extend generally forward from opposing sides 16 to define a horizontal axis of bracket 10. In the embodiment shown in FIG. 1, arms 26 are integrally joined to base member 18 although arms 26 may be attached to base member 18 by welding, for example. Arms 26 may be confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com