Modular room system and method

a modular and room technology, applied in the field of room structures, can solve the problems of only being able to both alternatives can be expensive, and the structure can only be altered by incurring the cost of additional construction or demolition, so as to achieve stronger and more stable upright, increase stability and strength, and increase the effect of stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

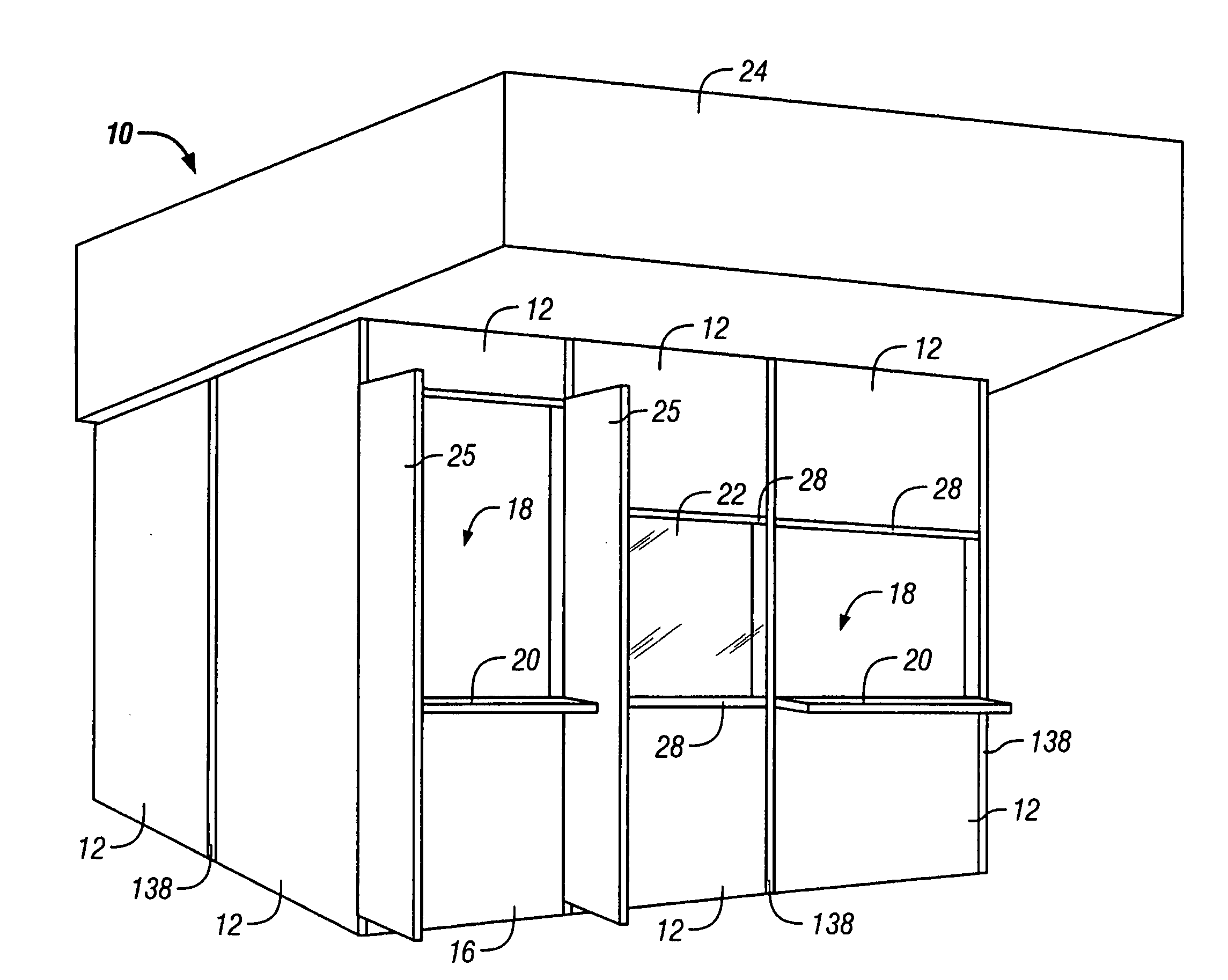

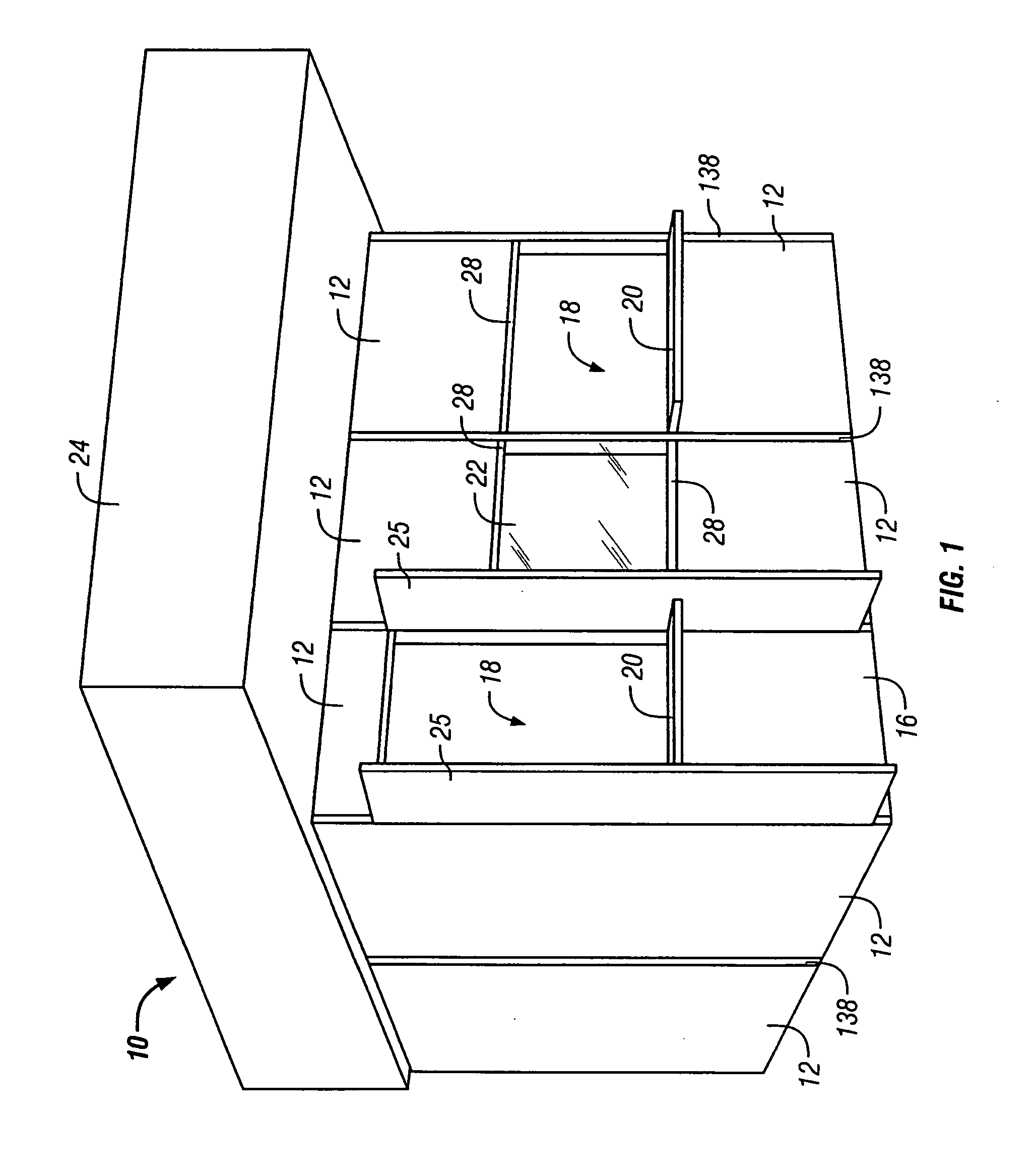

[0066] A modular room according to a preferred embodiment of the present invention is shown in FIG. 1, and is indicated generally at 10. In its various embodiments, the modular room 10 of the present invention is located partially or fully in another structure, such as a department store or other type of retail store, a shopping mall, or the like. Although the most preferred embodiments of the present invention are internal with respect to another surrounding structure, it should be noted that one or more walls of the room 10 can define an external wall of such a structure in other embodiments.

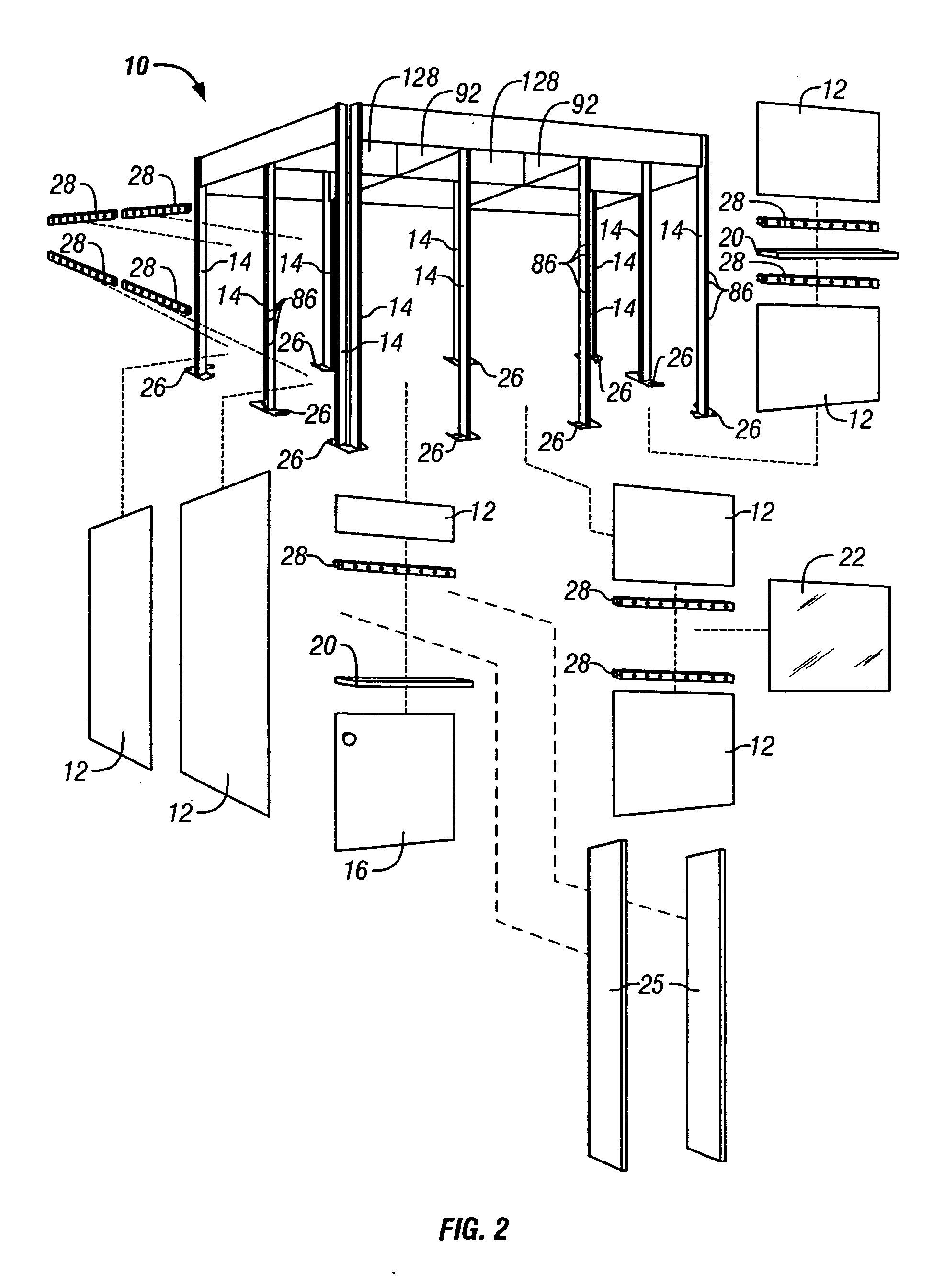

[0067] With continued reference to FIG. 1, the modular room 10 employs elements and structure that permit rapid assembly of the room 10. The room 10 preferably employs a number of standardized components and assemblies enabling such assembly. As described in greater detail below, these components and assemblies can include anchor plates, primary vertical posts or “uprights” connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com