Vacuum tray for vacuum packing

a vacuum bag and vacuum technology, applied in the directions of packaging, transportation and packaging, containers, etc., to achieve the effect of convenient vacuum bag vacuum packing, simple structure and smooth vacuum bag vacuum packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

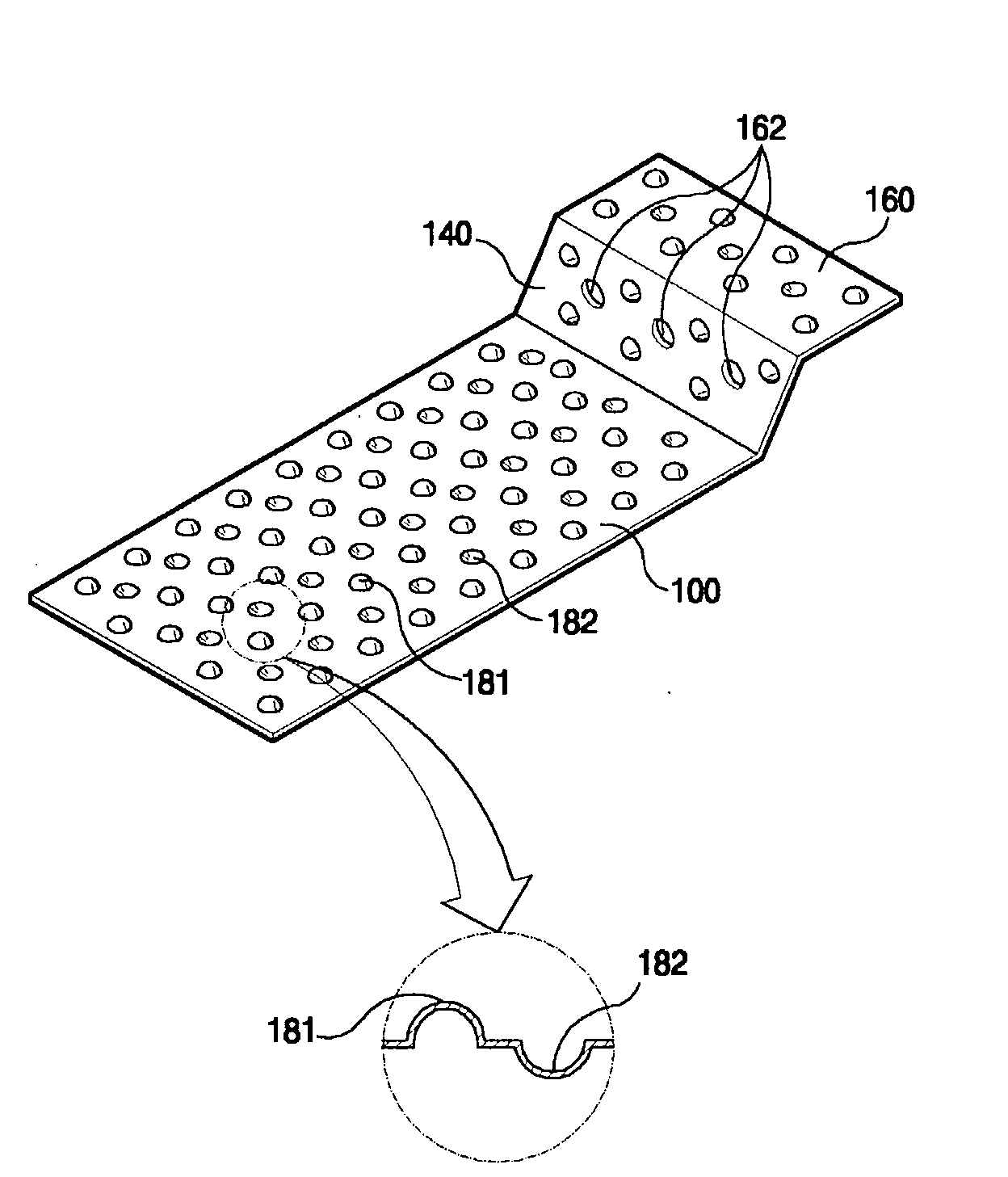

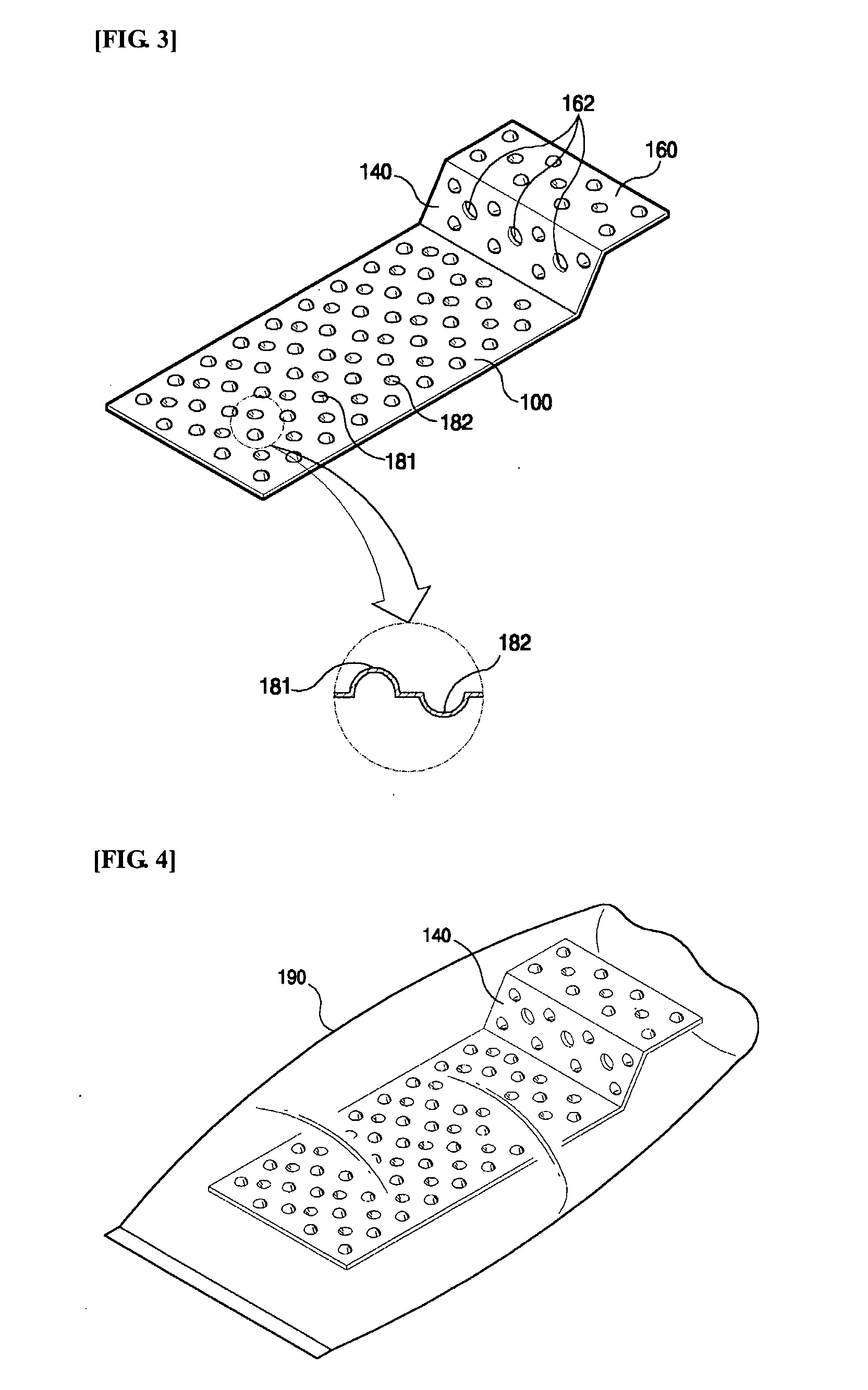

[0031]FIG. 3 shows a vacuum tray for vacuum packing according to a preferred embodiment of the present invention. FIG. 4 is a view showing the vacuum tray which is inserted along with an object into a vacuum bag. As shown in FIG. 3, the vacuum tray for vacuum packing according to the present invention includes a bottom plate 100 which is inserted into a vacuum bag to support thereon an object to be packed; and an inclined plate 140 which is integrally coupled to a front end of the bottom plate 100 and is inclined at a predetermined angle with respect to the bottom plate 100. Embossments such as protrusions 181 and 182 are formed on and under both the bottom plate 100 and the inclined plate 140.

[0032] Such embossments may be formed only on inner surfaces of both the bottom plate 100 and the inclined plate 140, like the protrusions 181 formed on their inner surfaces. Alternatively, the embossments may be formed only on their outer surfaces, like the protrusions 182 formed on their ou...

second embodiment

[0041]FIG. 5 shows an airflow defining part integrated with a vacuum tray such as that shown in FIG. 3.

[0042] Referring to FIG. 5, it is understood that a first airflow defining part 200 is coupled to a front end of an upperplate 160 of the vacuum tray such as that shown in FIG.3. Preferably, the first airflow defining part 200 is integrated with the vacuum tray through an injection molding process. To reduce the material cost and to allow it to be cut easily, the first airflow defining part 200 is tinier than the upper plate 160.

[0043] The first airflow defining part 200 must be made of material which can be thermally bonded to a vacuum bag. The reason is that, when an opening of the vacuum bag is thermal-sealed by a thermal sealing means 50, the first airflow defining part 200 must be thermally bonded to the vacuum bag together.

[0044]FIG. 6 shows a vacuum tray which is not embossed in regions other than a first airflow part 200, unlike the vacuum tray of FIG. 5. In the case tha...

third embodiment

[0052]FIG. 7 shows a coupling of a second airflow defining part 330 to a vacuum tray such as that shown in FIG. 3. A vinyl sheet having embossments is used as the second airflow defining part 330. Furthermore, a piece cut from a typical vinyl bag having embossments maybe used.

[0053] The second airflow defining part 33 is coupled to an upper plate 160 of the vacuum tray by a holder 310. The holder 310 includes a coupling part 311, a support plate 312 and a clamp 313. The coupling part 311 serves to couple the holder 310 to the upper plate 160 of the vacuum tray. As shown in FIG. 12, the coupling part 311 has a U-shaped cross-section. The upper plate 160 is inserted into a hole of the coupling part 311 having the U-shaped cross-section, so that the coupling part 311 is coupled to the upper plate 160.

[0054] The support plate 312 supports thereon the second airflow defining part 330 such as a piece of vacuum bag. The clamp 313 holds the second airflow defining part 330 placed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com