Modular raintank

a raintank and module technology, applied in the field of modules, can solve the problems of large amount of plastic material, limited water flow through the sidewall, and only approximately 50% of the volume, and achieve the effects of reducing the thickness of the strut, saving plastic material, and increasing the surface opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The following discussion describes in detail several embodiments of the invention and multiple variations of those embodiments. This discussion should not be construed, however, as limiting the invention to those particular embodiments. Practitioners skilled in the art will recognize numerous other embodiments as well.

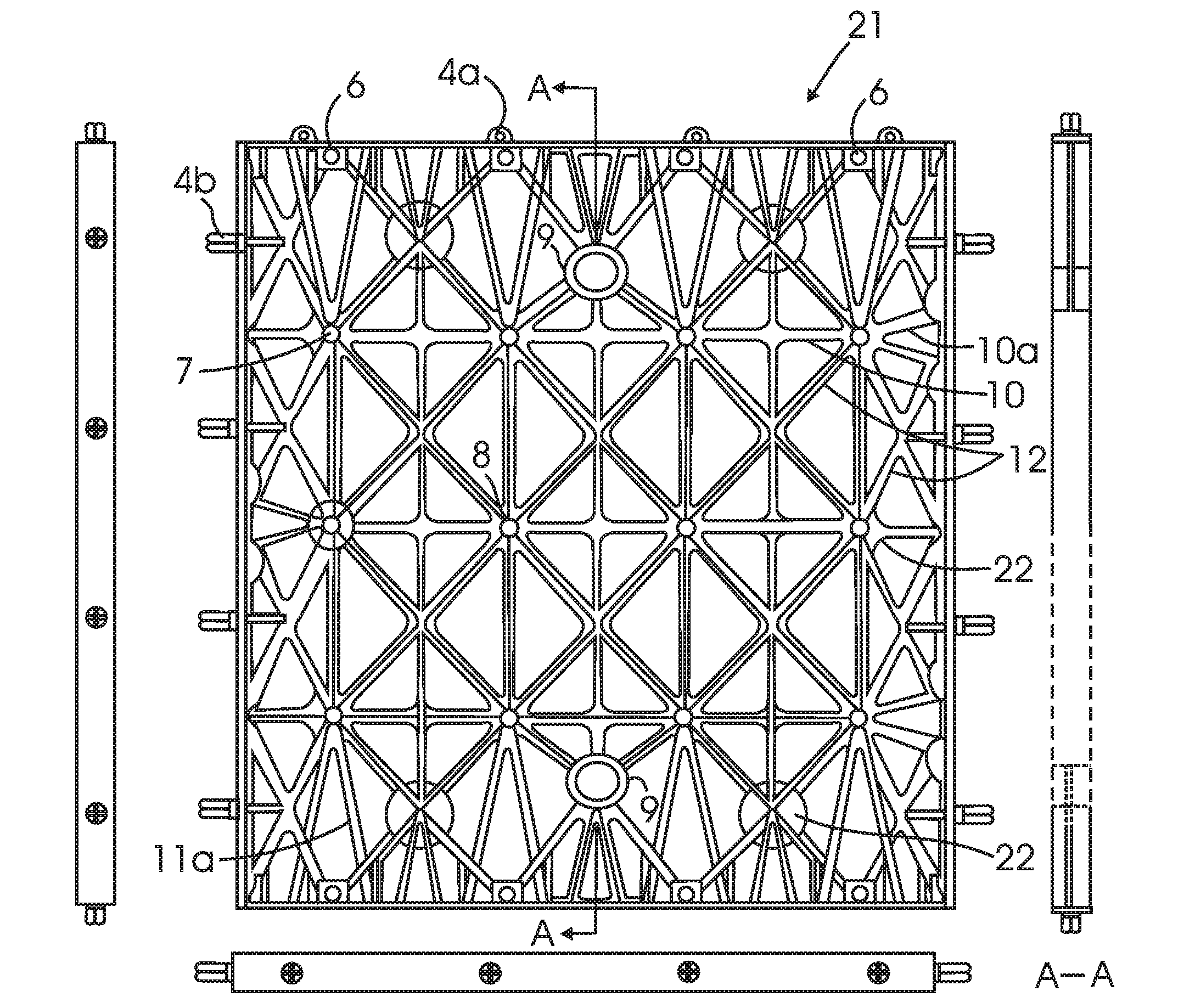

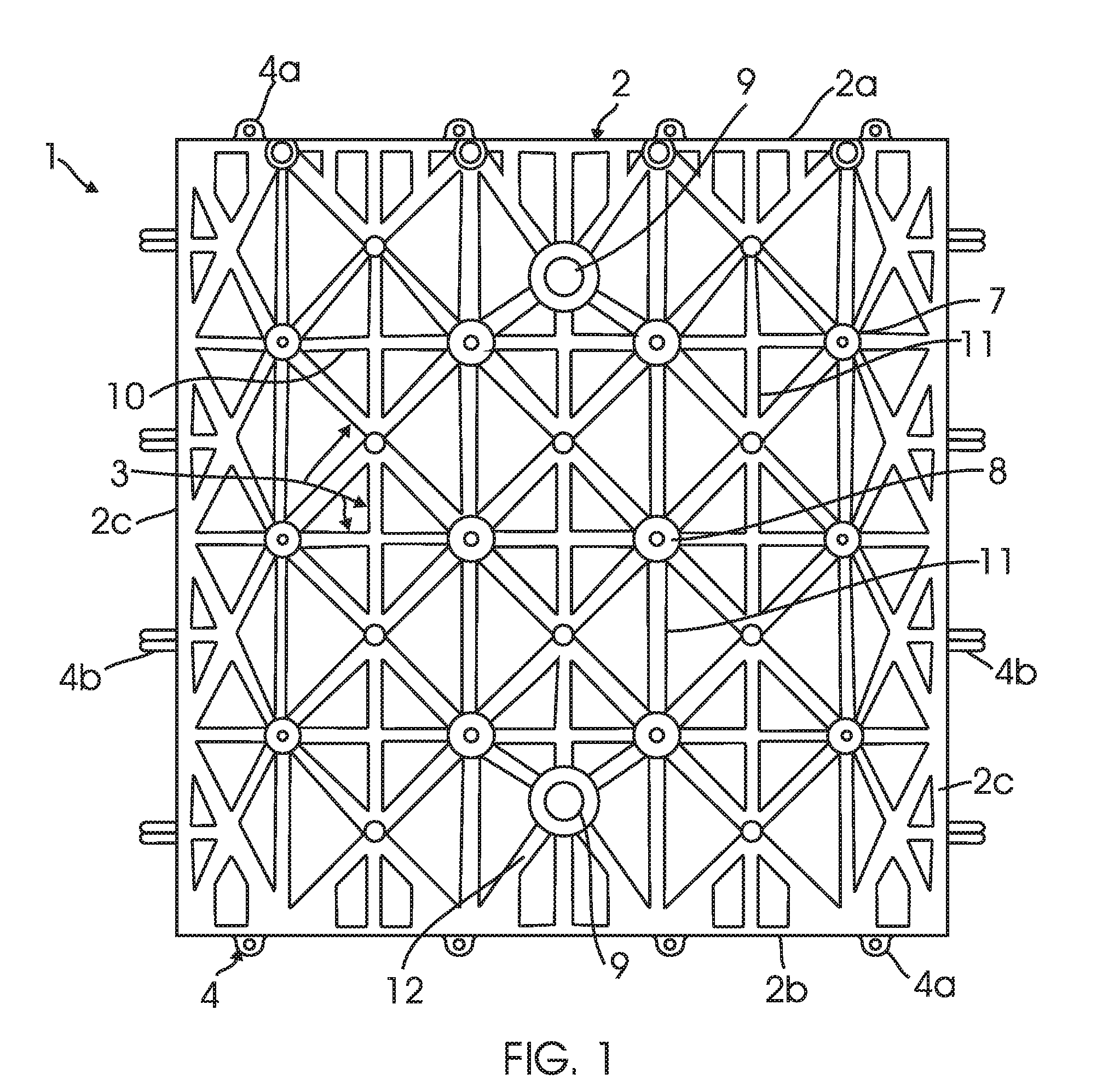

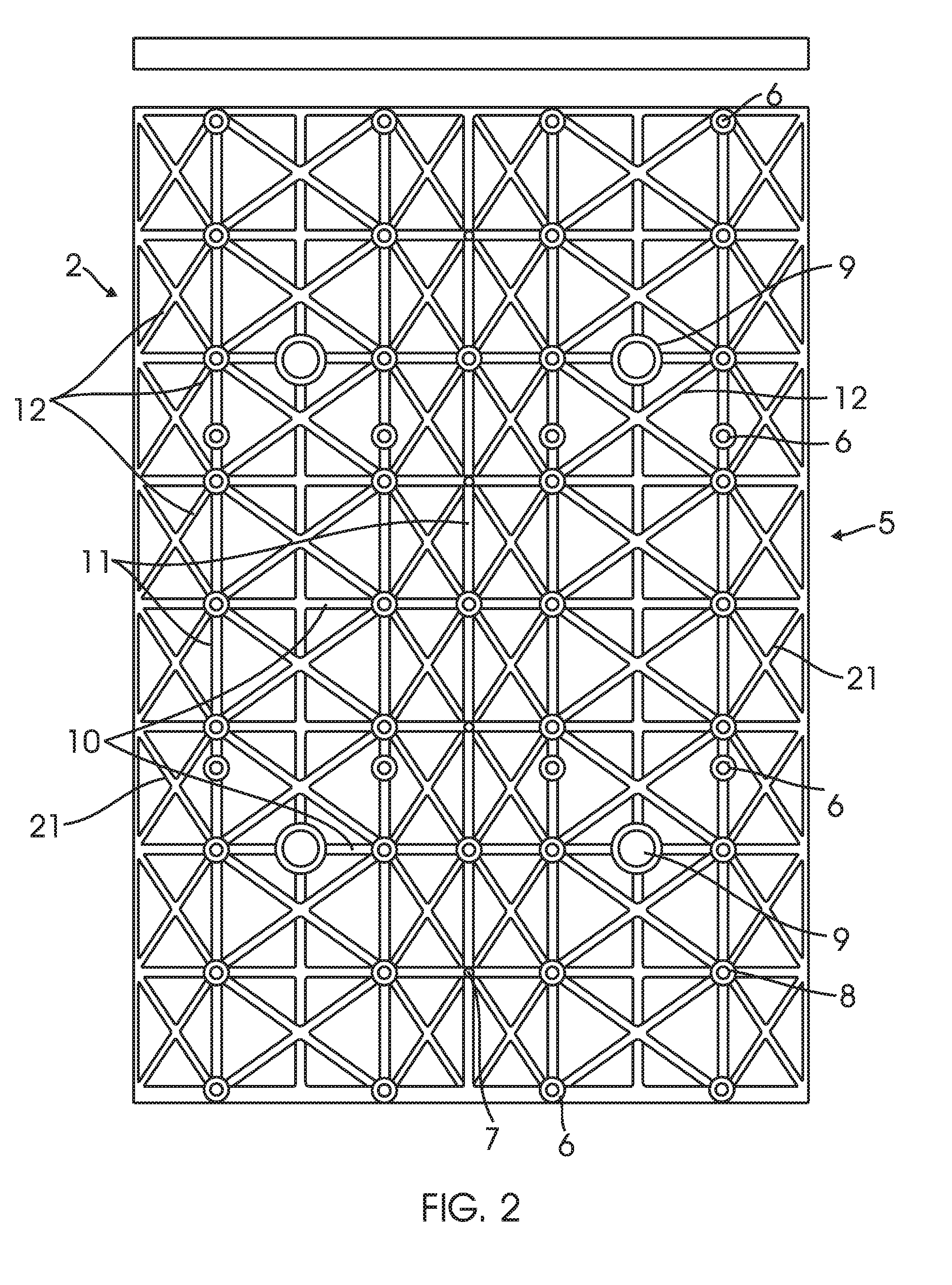

[0050]Referring to FIG. 1, one embodiment of the present invention is modular wall panel 1. The shape of wall panel 1 is defined by four periphery frame members 2. In the illustrated embodiment, the wall panel includes a top periphery frame member 2a, a bottom periphery frame member 2b, and two side periphery frame members 2c. Internal strut members 3 extend between the periphery frame members 2. Stud members 4 extend outwardly from periphery frame members 2.

[0051]As seen in FIG. 1, the stud members 4 can be of different sizes, with shorter studs 4a being located on the top periphery frame member 2a and the bottom periphery frame member 2b, and the longer studs 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com