Anisotropic Conductive Film Carrying Tape and Packaging Method

a conductive film and carrying tape technology, applied in the direction of film/foil adhesives, transportation and packaging, electric/magnetic/electromagnetic heating, etc., can solve the problems of reducing production efficiency, limiting the radial size of the tape wound on the reel, and loss of time, etc., to achieve convenient and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

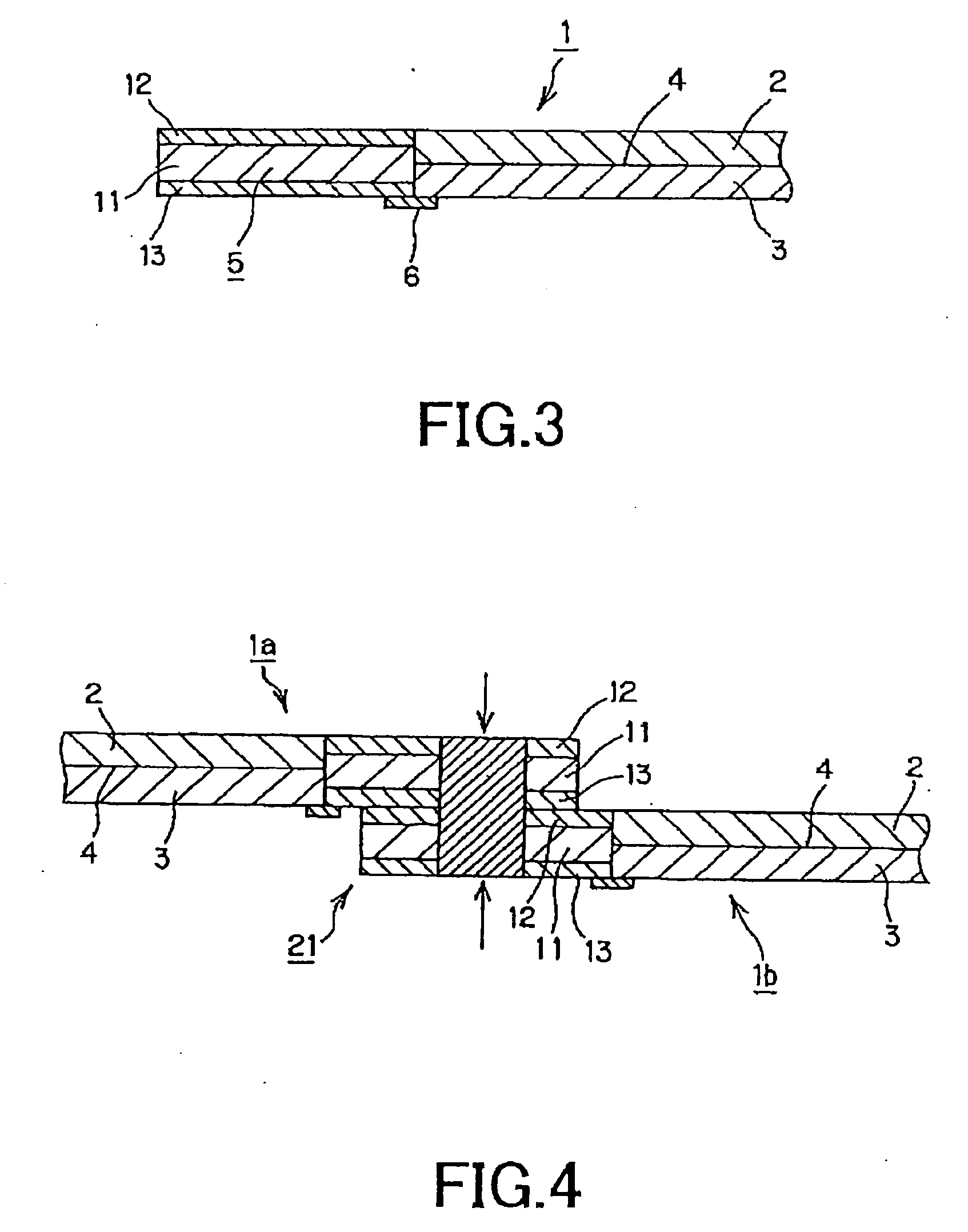

[0023] An embodiment of an anisotropic conductive film carrying tape 1 according to the present invention will now be described with reference to the drawings.

[0024] The main part of the anisotropic conductive film carrying tape 1 of the present embodiment is a base film 3 of synthetic resin on which has been affixed an anisotropic conductive film 2, as shown in FIG. 3. This base film 3 may be a film of PET (polyethylene terephthalate), for example. That is, the anisotropic conductive film carrying tape 1 is mainly formed by the anisotropic conductive film 2, the PET film, as the base film 3, and a release part 4, when looking along the direction of tape thickness. The release part 4 is formed by applying releasing processing to the facing side(s) of the anisotropic conductive film 2 and / or the base film 3. Meanwhile, the release part 4 may be formed by providing a layer of a releasing agent, such as silicone, in a space between the anisotropic conductive film 2 and the base film 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Anisotropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com