Method for manufacturing stacked package structure

a technology of stacked package and packaging structure, which is applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of substantial increase in cost, serious deterioration of stacked package structure, and greatly reduced yield of stacked package process, so as to reduce the area occupied by the package structure and reduce the area of the printed circuit board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

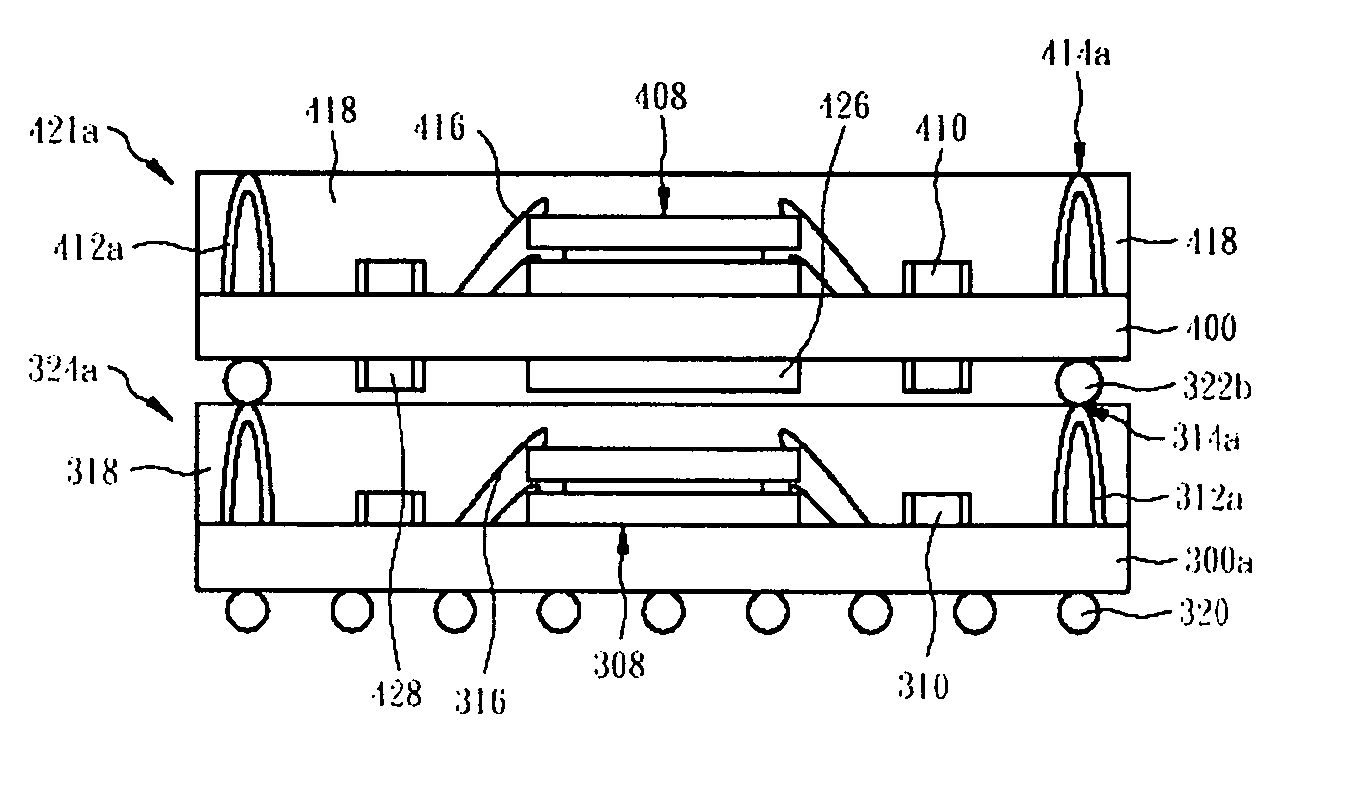

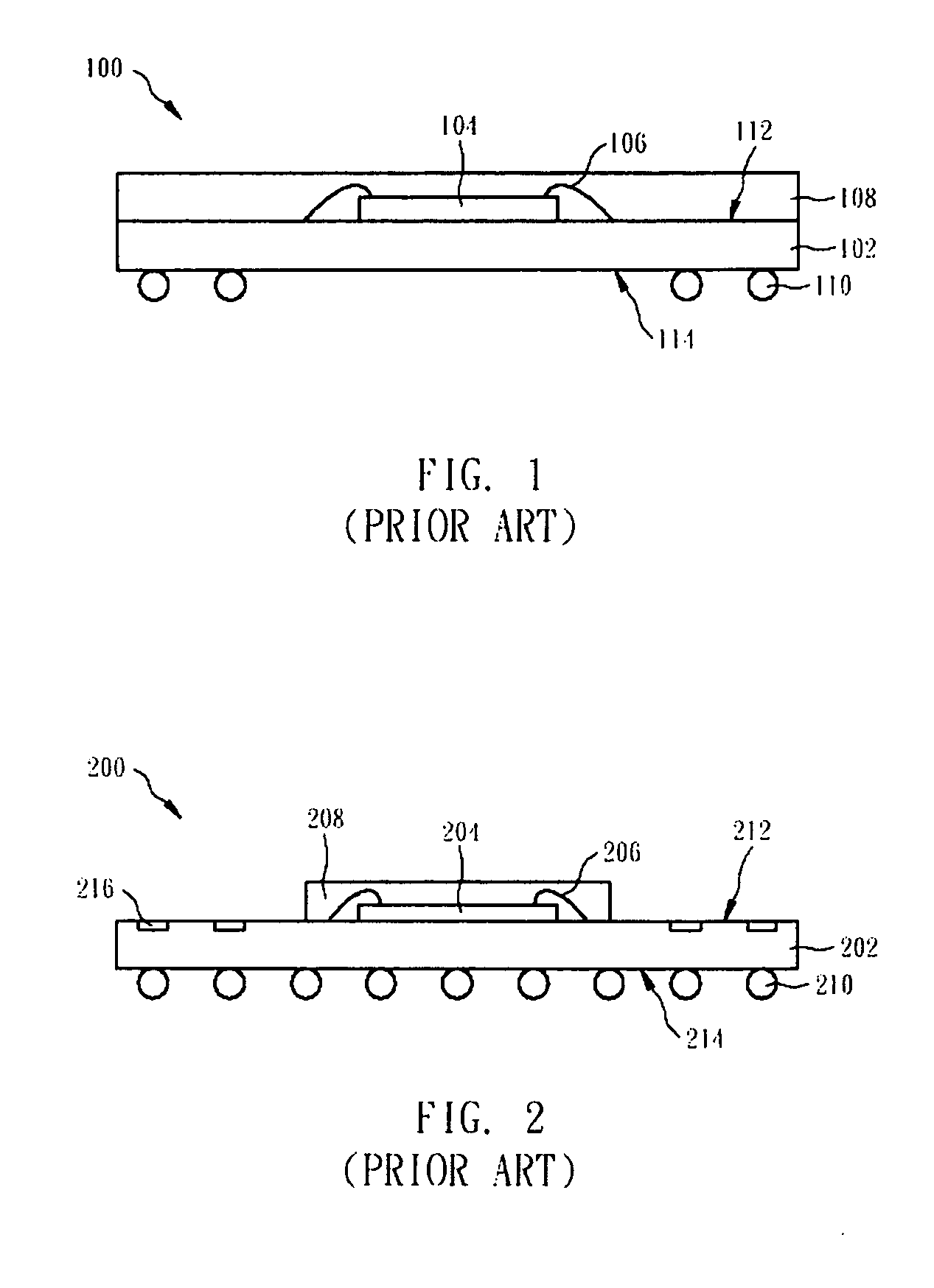

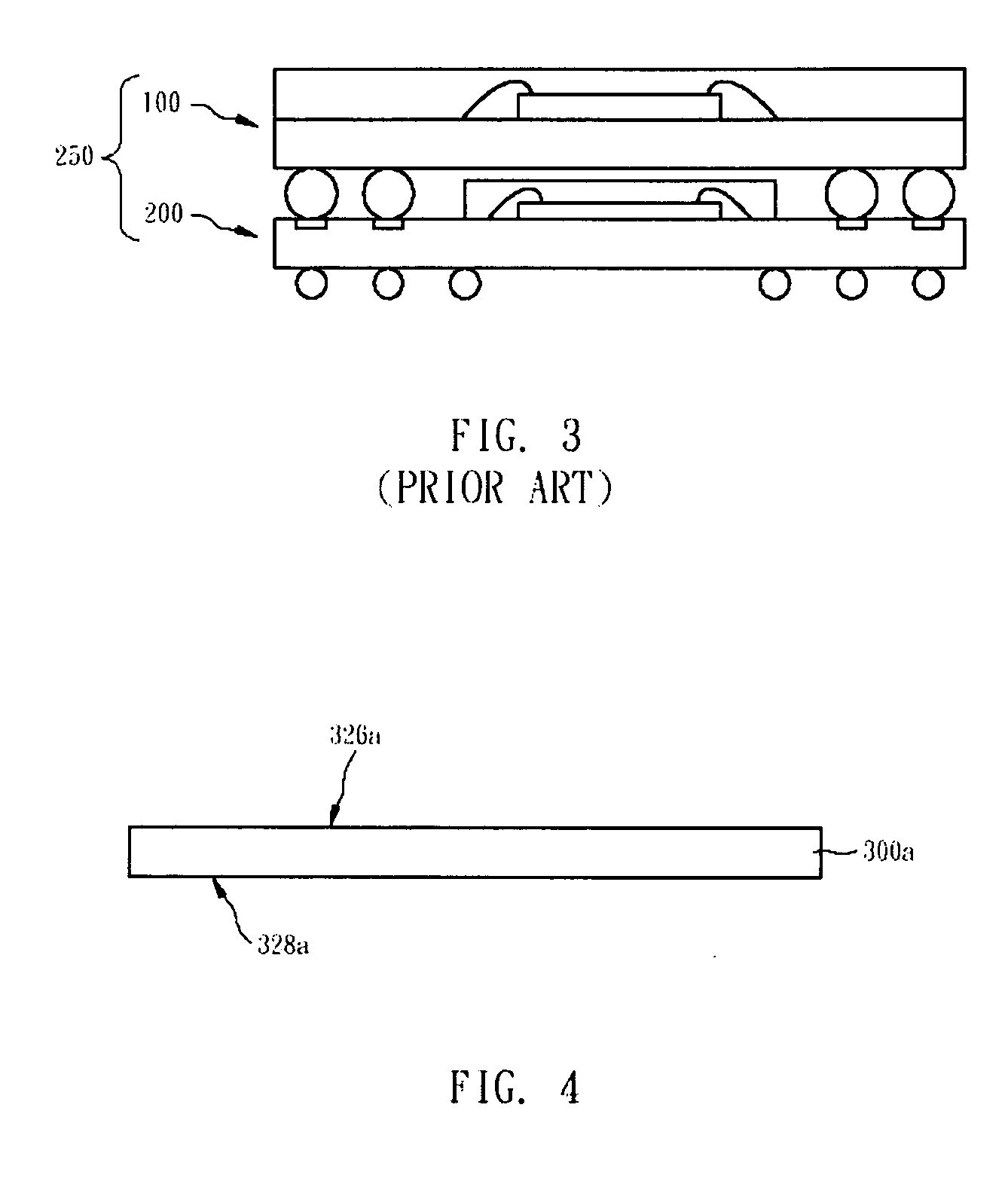

[0021] The present invention discloses a stacked package structure and a method for manufacturing the same. In order to make the illustration of the present invention more explicit and complete, the following description is stated with reference to FIGS. 4 to 12c.

[0022] Referring to FIGS. 4 to 9b and FIG. 12a, in which FIGS. 4 to 9b are schematic flow diagrams showing the process for manufacturing a stacked package structure in accordance with a first preferred embodiment of the present invention. In the fabrication of a stacked package structure of the present invention, a chip package structure 324a, such as illustrated in FIG. 8, is typically formed firstly. In the formation of the chip package structure 324a, a substrate 300a or a substrate 300b is provided, in which the substrate 300a or the substrate 300b may be a printed circuit board, for example. Alternatively, the substrate 300a or 300b can be replaced by other chip carrier, such as a QFP leadframe or a QFN leadframe. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com