Burner head for a gas stove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In order to describe the structure and characteristics of the present invention in detail, a preferred embodiment accompanying with drawings is explained in the following.

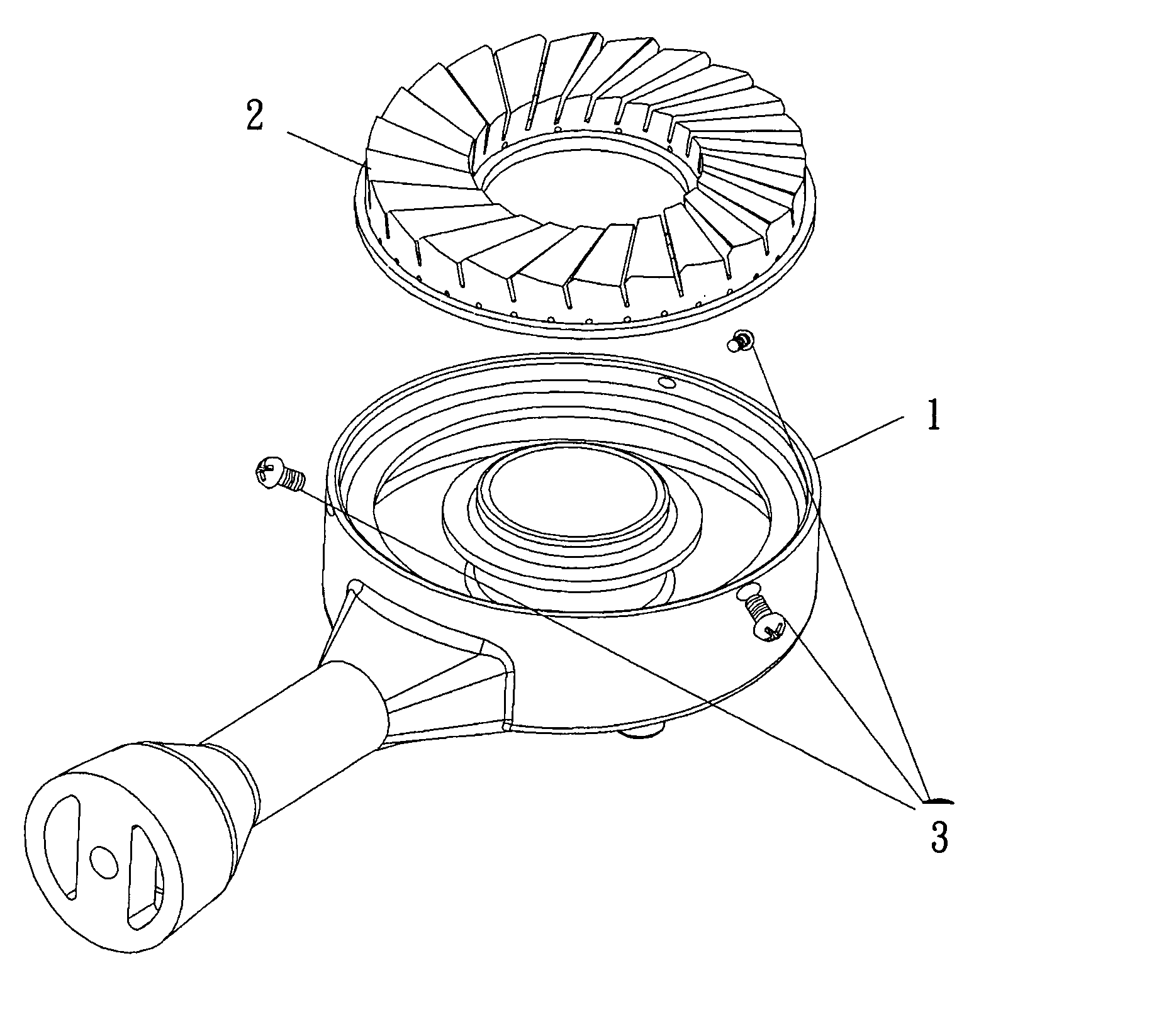

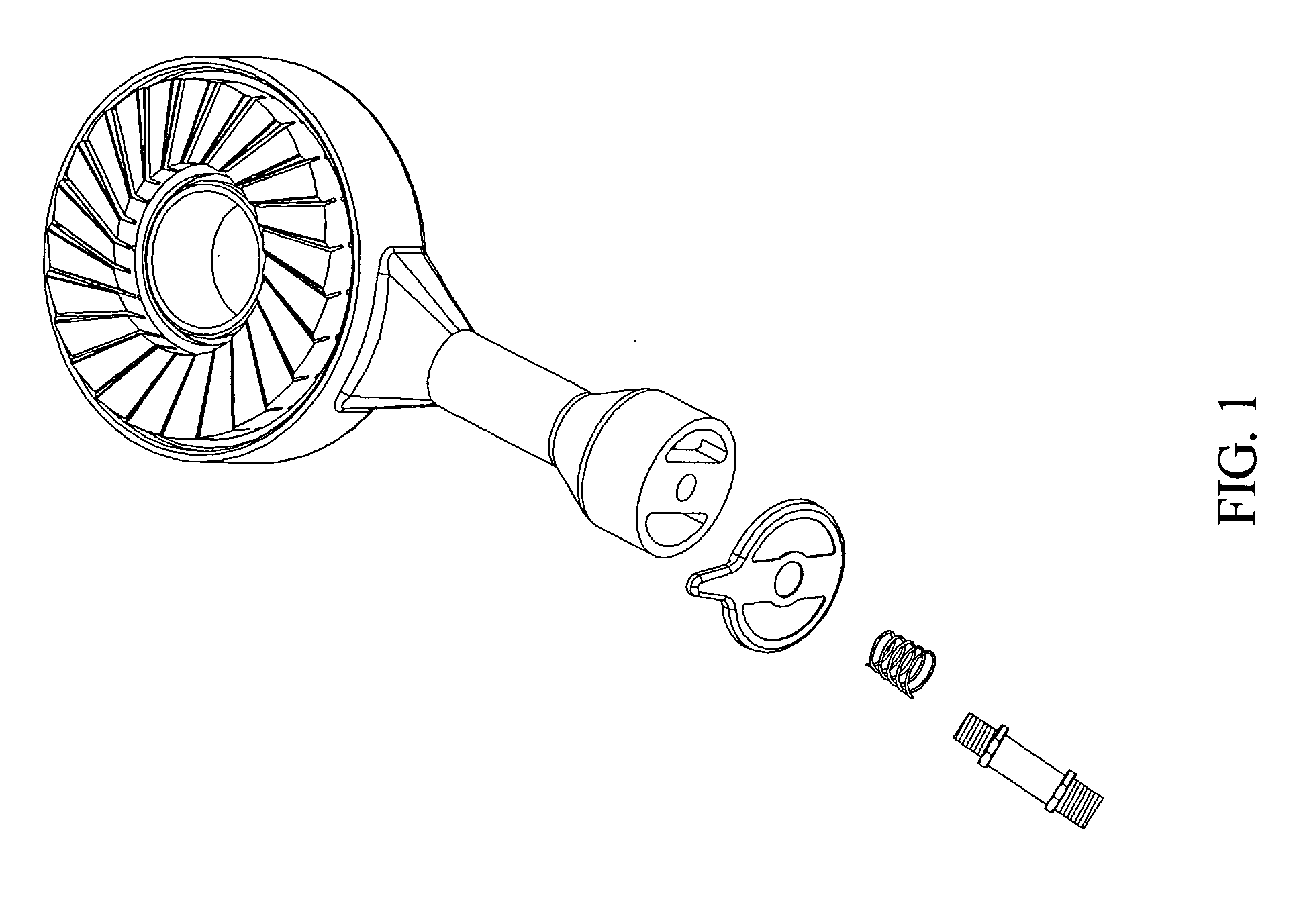

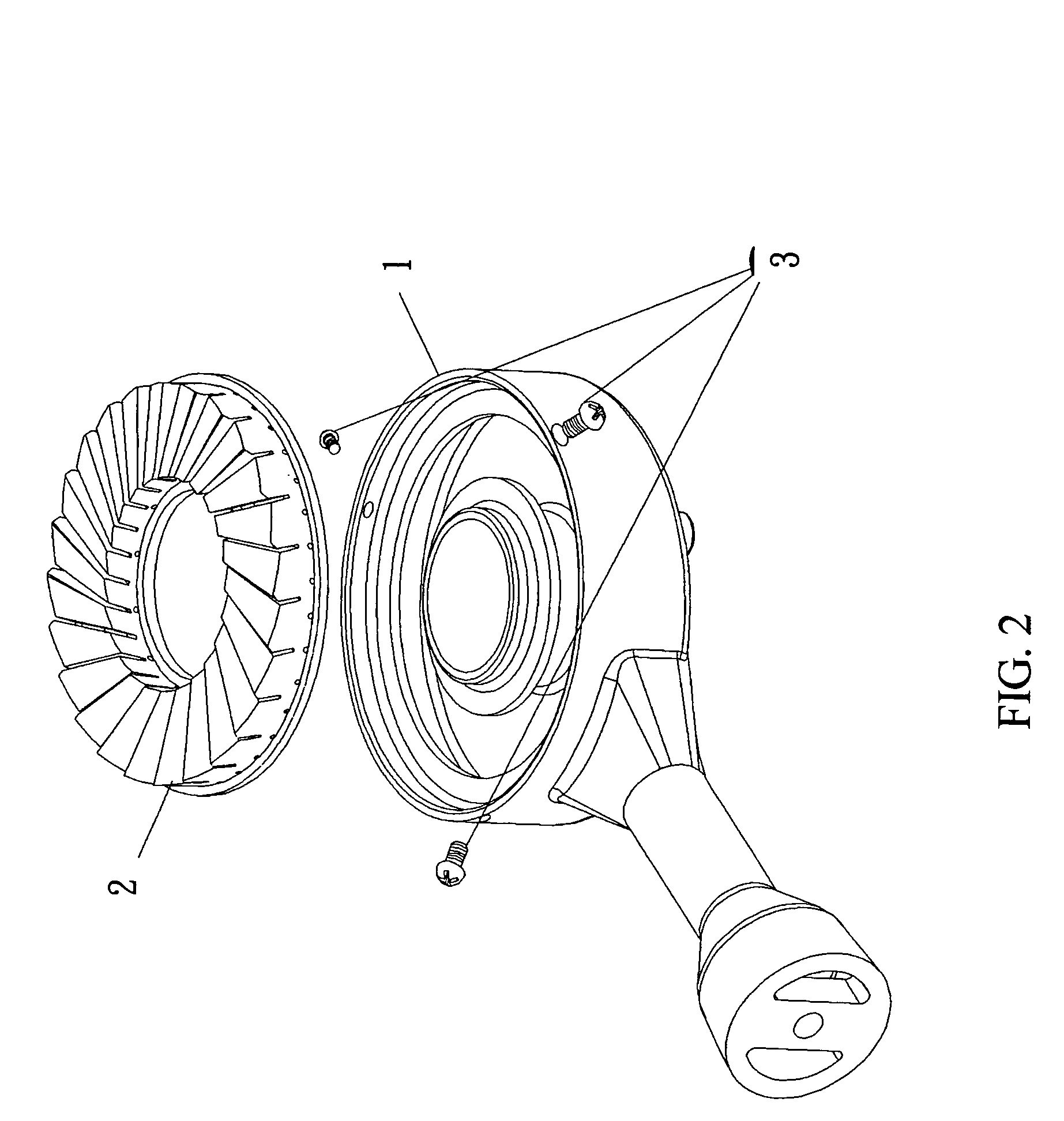

[0018]As FIG. 1 through FIG. 4 shows, the burner head 1 of the present invention includes a base 10 and an annular cover 20 in which a circle of small holes 21 through inner and outer surroundings of the annular cover 20 formed on the lower portion of the annular cover 20, and a plurality of gas-exiting grooves 22 through the inner and outer surroundings of the annular cover 20 disposed on the upper portion of the annular cover 20. The gas-exiting grooves 22 are not disposed in radial directions from the center of annular cover 20 but are disposed in a way that a predetermined angle a is contained between the adjacent gas-existing grooves 22. As such, the rotating flame can be formed to attain the even-burning effect, and it can sufficiently burn the oxygen in the air. It is not only that the gas is burned su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com