Pressure Regulating Valve

a pressure regulating valve and valve body technology, applied in the direction of fluid pressure control, process and machine control, instruments, etc., can solve the problems of low durability of rubber seals that are typically used as seals, large fluctuations in the secondary pressure of the pressure regulating valve, and insufficient damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

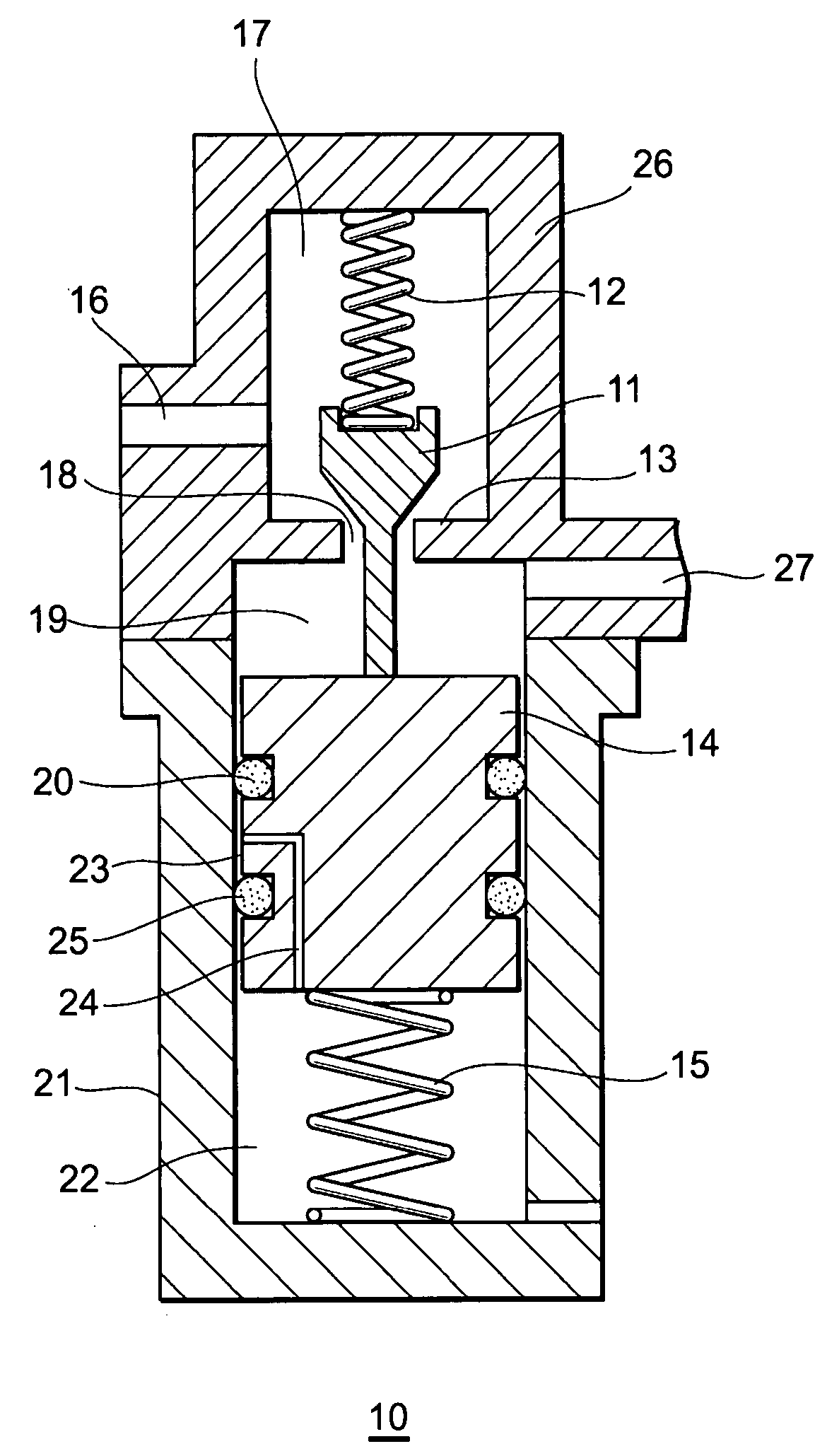

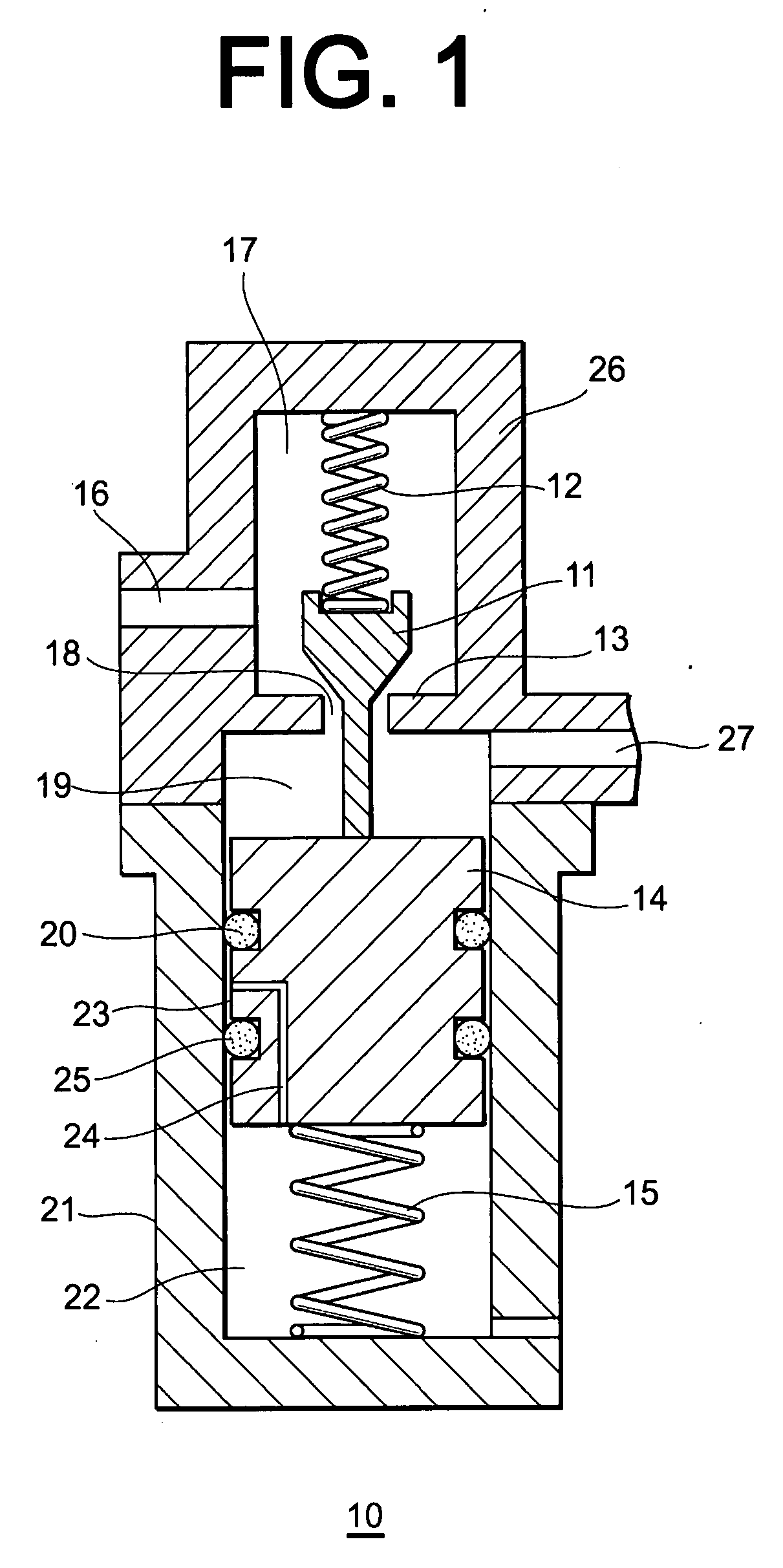

[0039] The following is a description with reference to FIG. 1 of a first embodiment of a pressure regulating valve 10 of the present invention.

[0040] In FIG. 1, numeral 11 indicates a poppet valve, numeral 12 indicates a spring constituting urging means for the poppet valve, numeral 13 indicates a seat, numeral 14 indicates a piston, numeral 15 indicates a spring constituting piston urging means, numeral 16 indicates a high-pressure gas path (inlet-path), numeral 17 indicates a primary chamber of the pressure regulating valve, numeral 18 indicates a path, numeral 19 indicates a secondary chamber of the pressure regulating valve, numeral 20 indicates a ring-type seal, numeral 21 indicates a cylinder (case), numeral 22 indicates a reference pressure chamber (reference pressure chamber), numeral 23 indicates a space, numeral 24 indicates a path, numeral 25 indicates a damper, numeral 26 indicates a pressure regulating valve case, and numeral 27 indicates a low pressure gas path (outl...

second embodiment

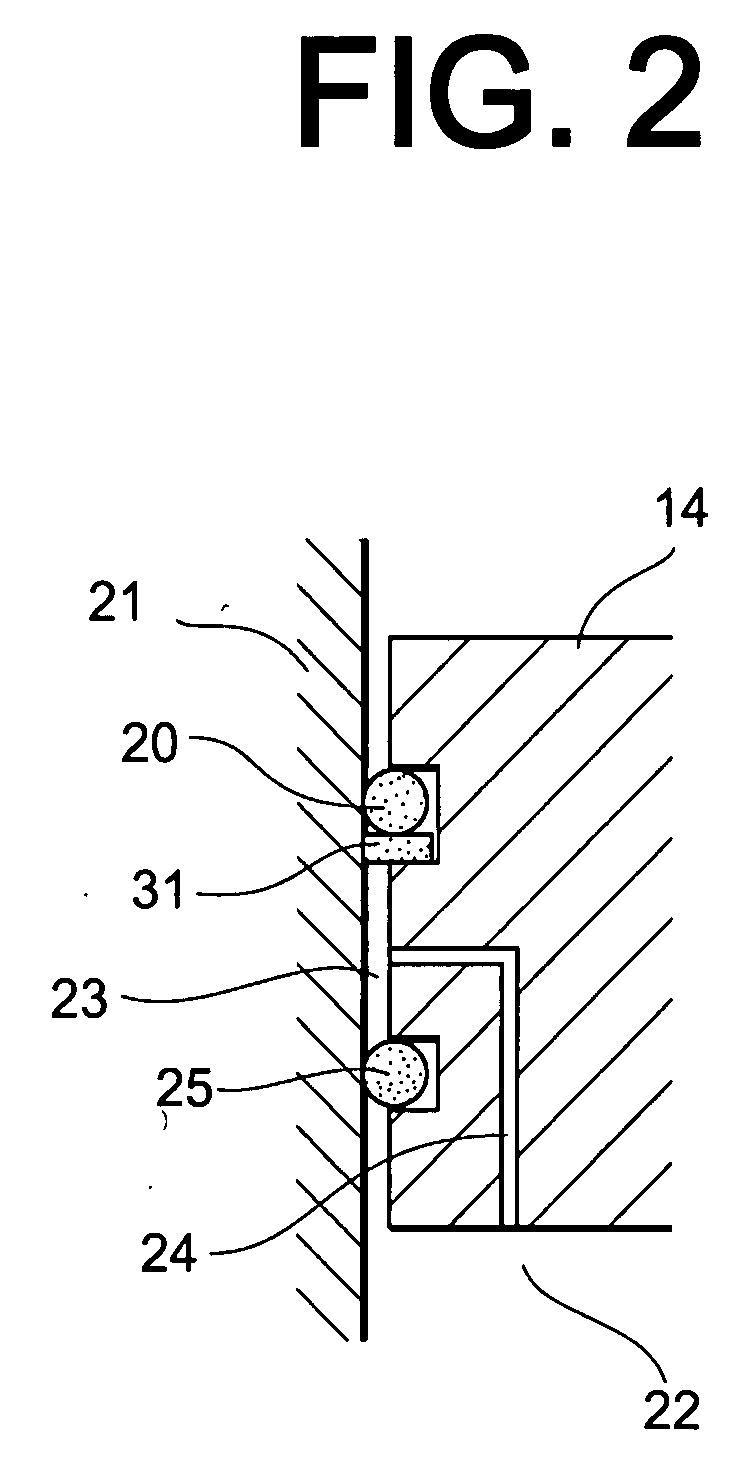

[0049]FIG. 2 shows an outline of a second embodiment of the present invention. In FIG. 2, portions corresponding to portions of FIG. 1 are given the same numerals and are not described.

[0050] In this embodiment, an annular back-up ring 31 is overlaid on the polymer material ring-type seal 20. The reliability of the seal is increased as a result of providing the back-up ring 31.

third embodiment

[0051]FIG. 3 shows a third embodiment of the present invention. FIG. 3(A) shows an outline of an example of a further configuration for the polymer material ring-type damper 25 and FIG. 3(B) shows an example of a partial cut-away view from above taken along A-A′ of FIG. 3(A). In FIG. 4, portions corresponding to portions of FIG. 1 are given the same numerals and are not described.

[0052] In this example, minute undulations 32 are formed at a contact surface for an inner wall surface of the cylinder 21 of the damper 25 in place of the path 24 of the piston 14 or alternatively, the surface is roughened so that gas can communicate between the space 23 and the reference pressure chamber 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com