Pillow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

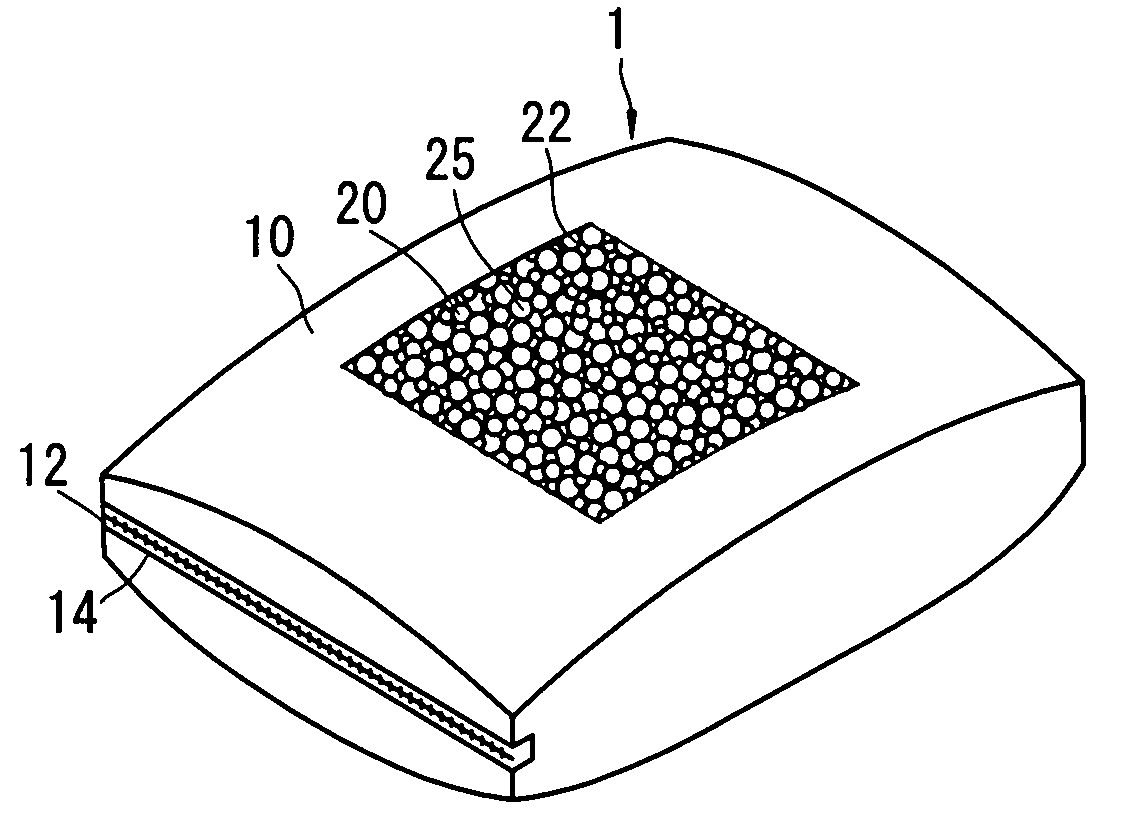

example 1

[0029]The bag was 33 cm long, 48 cm wide and 6 cm high. The linear member was a rubber string prepared by covering polyurethane rubber with polyester knitting yarn. The rubber string was 1.2 mm diameter and 60 cm long. The rubber string had an elongation of 100 percent. The chips were made of cypress and had a diameter of 12 mm. Eighty pieces of chip assemblies were prepared by passing fifty-seven chips over each rubber string. The chip assemblies were mixed and stuffed in the bag, with a filling factor of 85 percent.

[0030]The popularly used pillow stuffed with buckwheat shells was used as the criterion for judging the shape diversity, ease of forming, shape preservability and flexibility and the pillow of the present invention described above was compared with commercially available low-resilience urethane foam, feather and beads pillows. Table 1 shows the results of the comparison. The pillow of Example 1 proved to excel the buckwheat shell pillow and the other commercially availa...

example 2

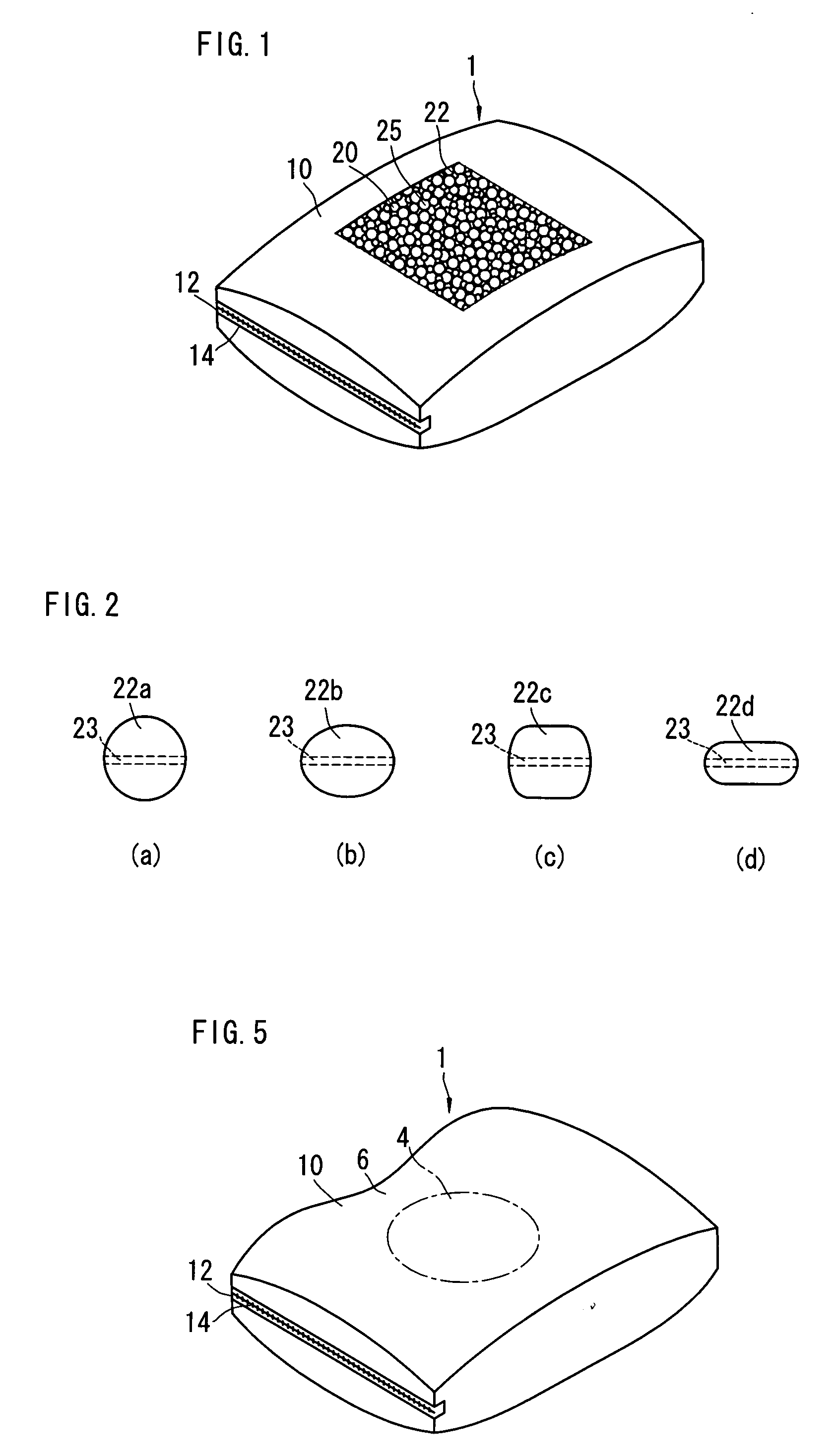

[0031]The bag was the same one as that used in Example 1. The chips were made of cypress and spherical in shape, having seven different diameters between 4 and 15 mm. The linear members were rubber strings similar to those used in Example 1, having lengths of 30, 60 and 120 cm. The rubber strings had an elongation of 100 percent. Chip assemblies were prepared by passing chips throughout the entire length of each rubber string. Twenty-one types of chip assemblies totaling 106 pieces were prepared by using chips of seven different diameters and rubber rings of three different lengths. Randomly mixed chip assemblies were stuffed in the bag with a filling factor of 85 percent. Table 2 shows the combinations of the chips and rubber strings.

TABLE 2ConnectorChip(RubberChip AssemblyDiameter / String)120 cm60 cm30 cmFace to FaceDiameterNumberNumberNumberNumberNumberNumberDistance* (mm)(mm)of ChipsUsedof ChipsUsedof ChipsUsed15 / 141.583242421413 / 121.5105352426612 / 111.2113357429610 / 9 1.2129465633...

example 3

[0033]The bag and chip assemblies were the same as those used in Example 2. However, the chip assemblies were connected into a loop form and randomly stuffed in the bag. While the loops were 15, 30 and 60 cm in length, the filling factor was 85 percent.

[0034]The pillow prepared as described above was compared with the conventional pillow stuffed with buckwheat shells in terms of the shape diversity, ease of forming, shape preservability and flexibility and the pillow of the present invention described above was compared with commercially available low-resilience urethane foam, feather and beads pillows. Table 1 shows the results of the comparison. The pillow of Example 3 proved to excel the buckwheat shell pillow and the other commercially available pillows in all respects.

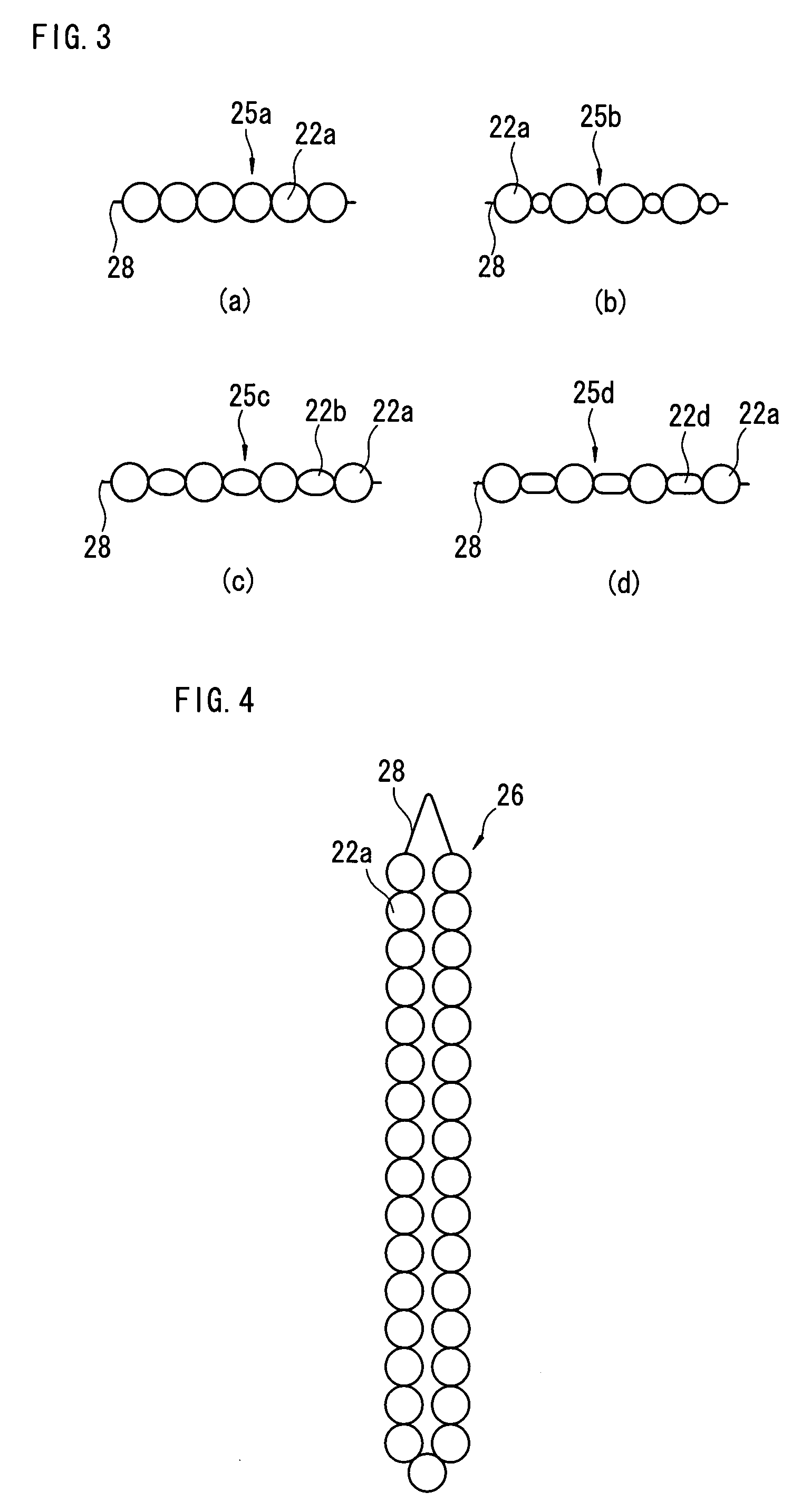

[0035]The present invention is not limited to the examples described above. For example, chip assemblies of wooden and synthetic resin chips may be stuffed together. Aromatic materials, such as lavender, rose and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com