Linear electrodynamic system and method

a linear electrodynamic and alternator technology, applied in the direction of dynamo-electric machines, mechanical energy handling, electrical apparatus, etc., can solve the problems of unsatisfactory performance of the electrodynamic system, the amount of mass used for the linear electrodynamic system can be undesirable, and the ease of use of the equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

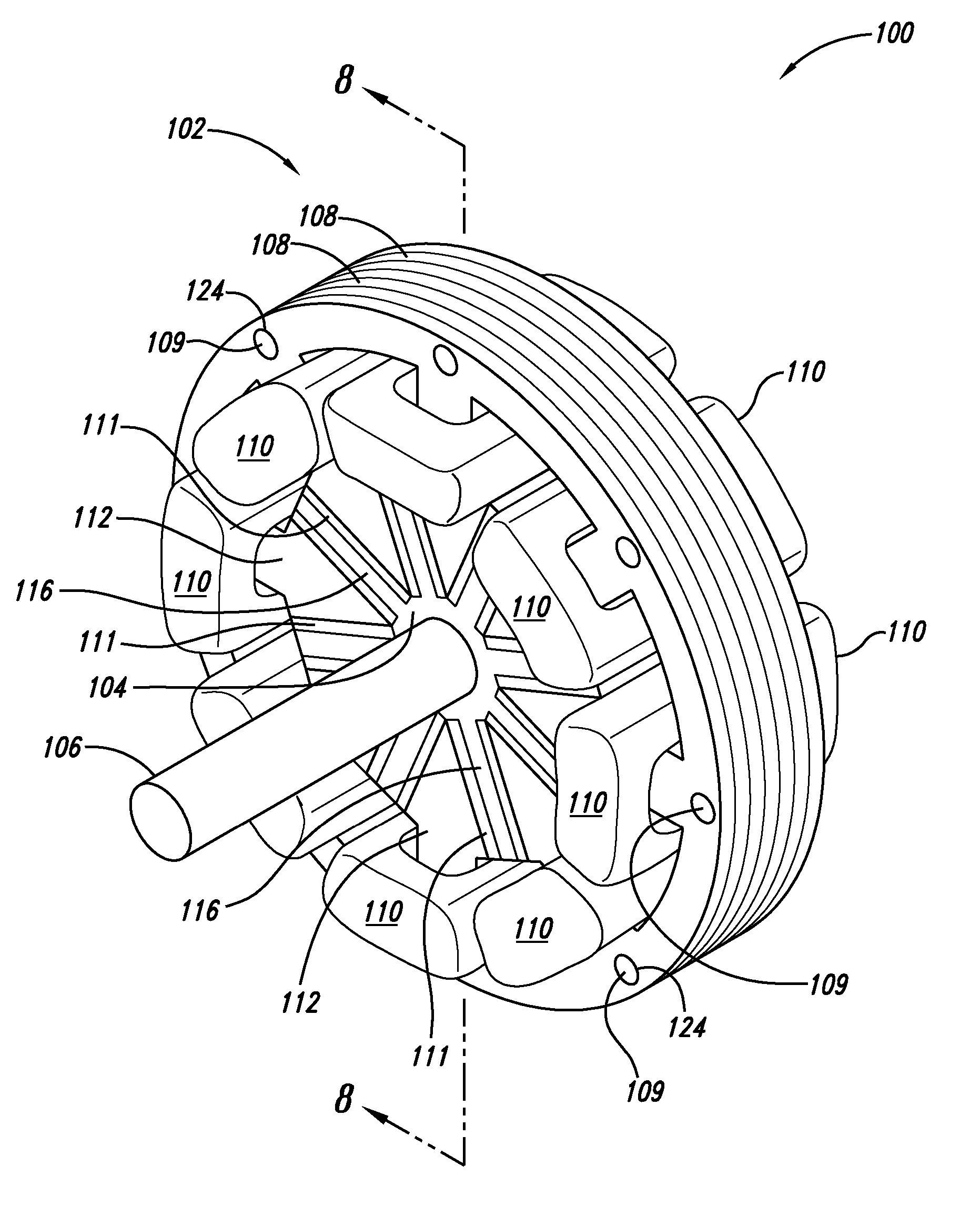

[0022] As will be discussed in greater detail herein, an innovative linear electrodynamic system and method is disclosed to convert linear mechanical motion into an electrical current such as for a linear alternator for heat engines including Stirling cycle engines, or to convert electrical current into linear mechanical motion such as for a linear motor associated with mechanical cooling devices. Due to innovative concepts embodied therein and described below, the innovative linear electrodynamic system has size and weight advantages over conventional linear electrodynamic systems.

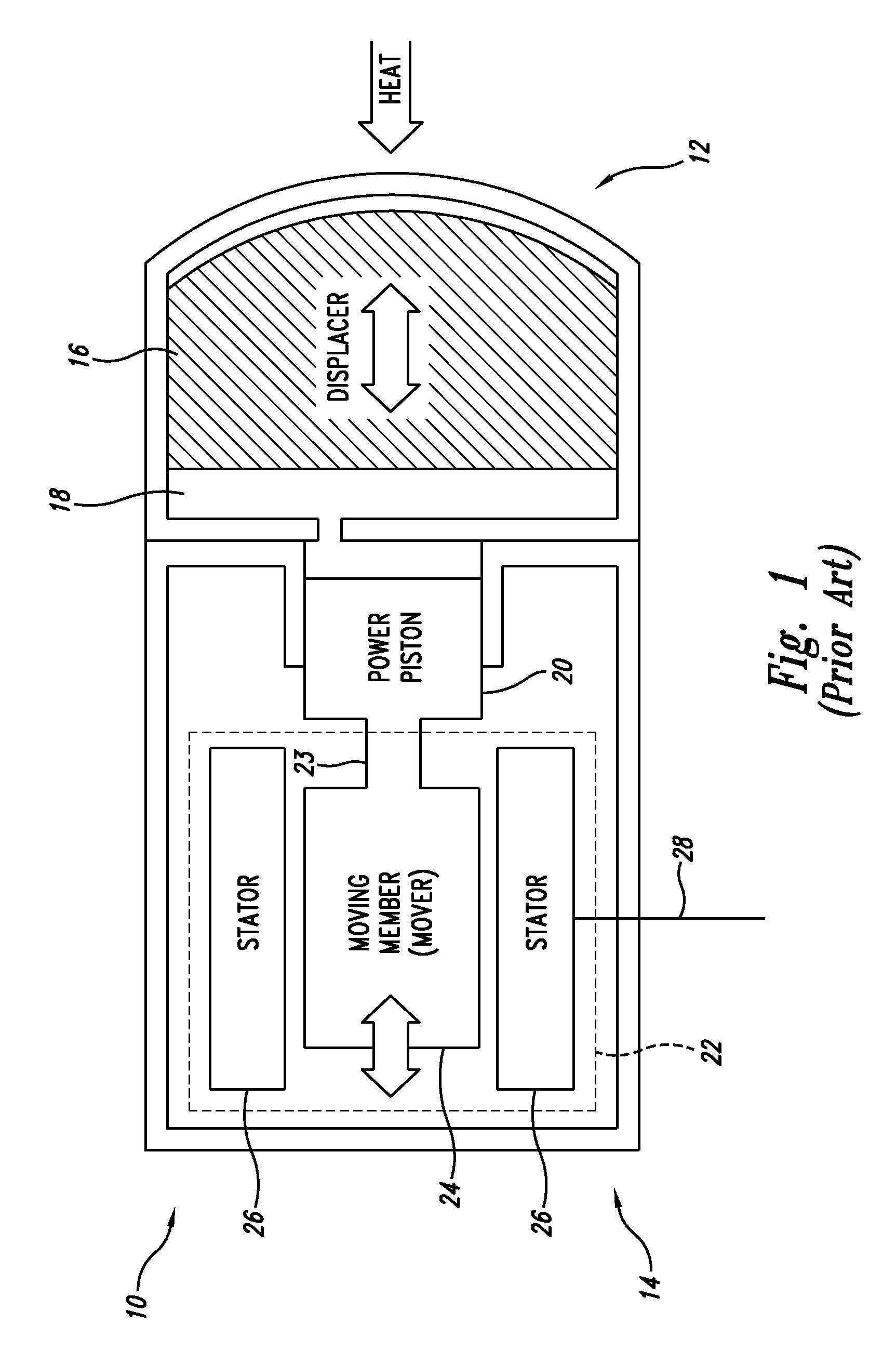

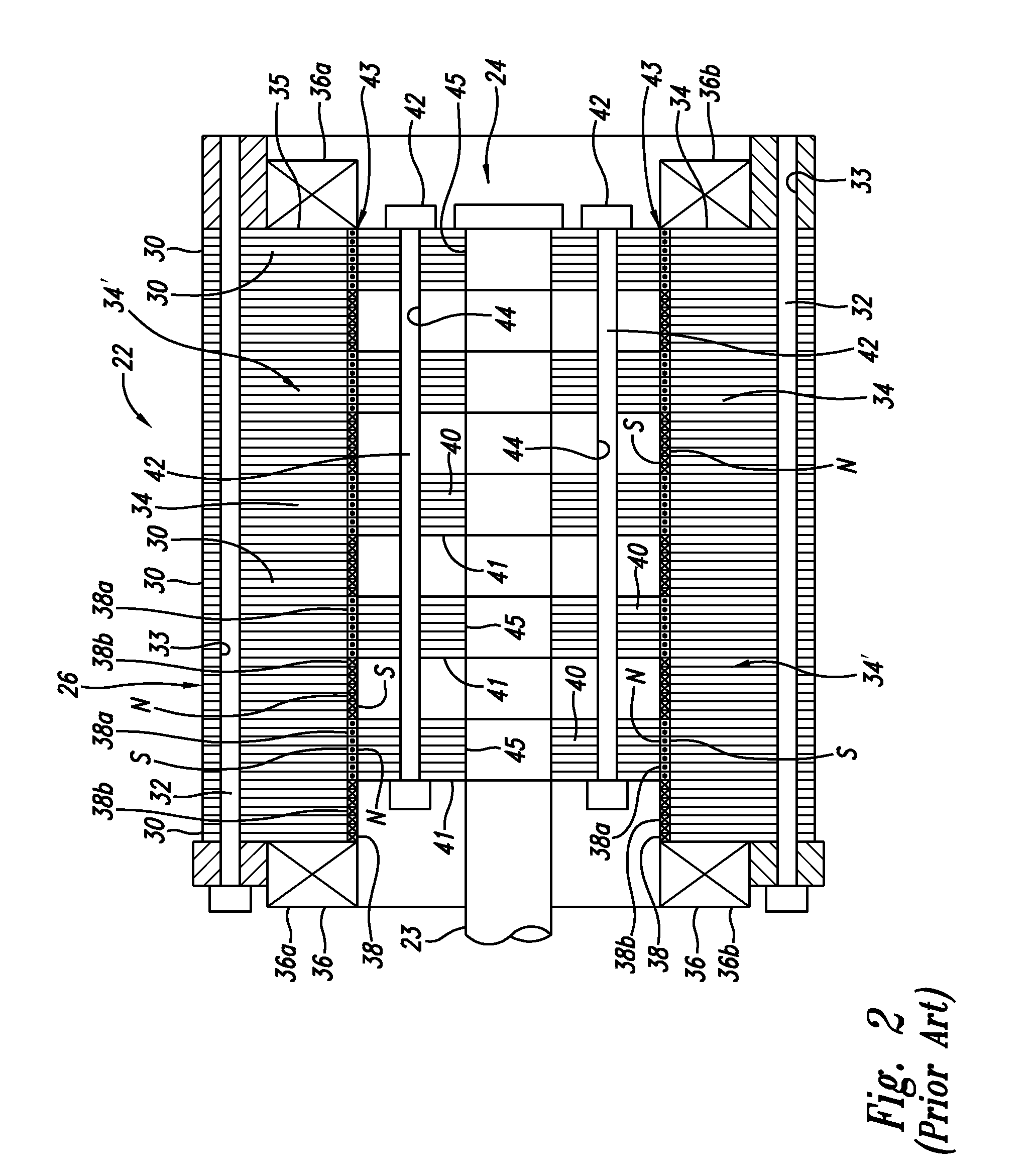

[0023] A conventional electrothermal system 10 using a heat module 12 and a power module 14 is shown in FIG. 1. When in the form of a Stirling cycle engine, the heat module 12 has a displacer 16 and working fluid 18 in fluid communication with a power piston 20, which is part of the power module 14. The power piston 20 of the power module 14 is connected to a conventional linear electrodynamic system 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com