Steering and propulsion arrangement for ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

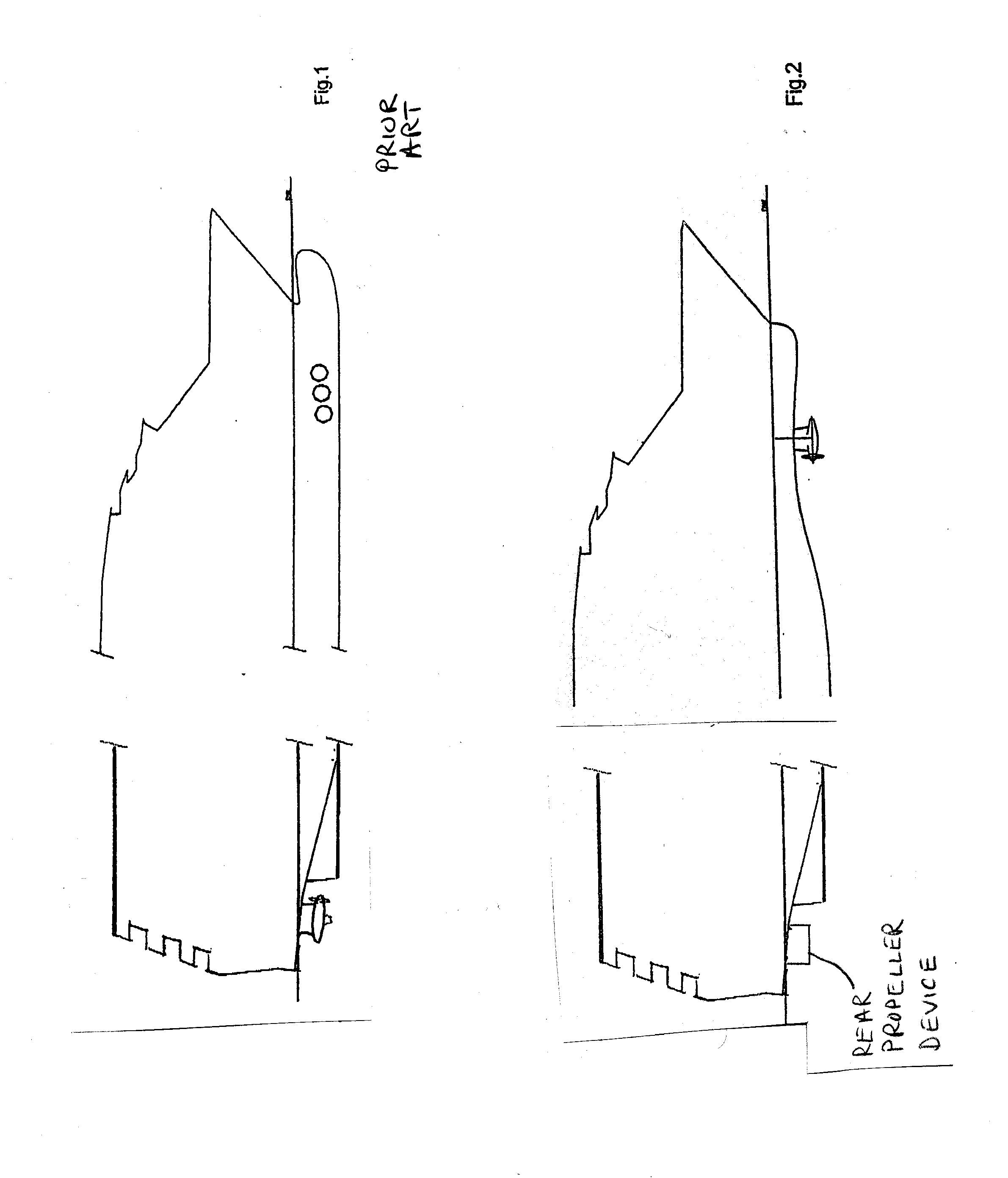

[0023] In a conventional solution according to the case shown in FIG. 1 there are three propeller devices arranged at the front of the ship on both sides, which devices affect only in the lateral direction of the ship, and contribute to the manoeuvering of the ship to quay and to its bringing off the quay respectively, and possibly to performing manoeuvering movements in the harbour area. When a large ship is concerned, the bow-thrusters require a lot of power, which is of no use in the ship's normal steering ahead.

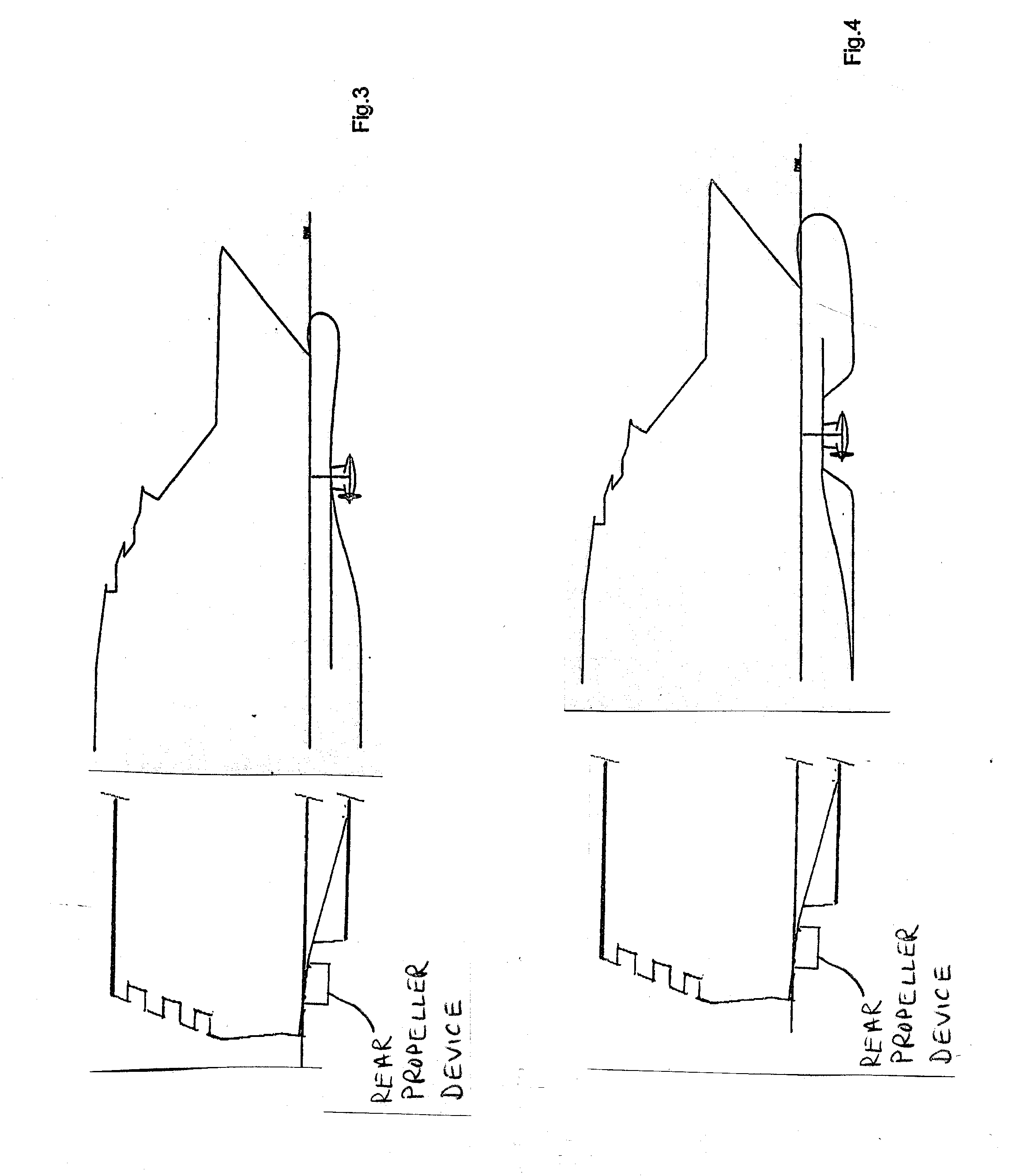

[0024]FIGS. 2-4 show how rudder propeller devices are arranged at the forebody of a vessel. Free turning of the rudder propeller device requires space and therefore the underwater hull requires modifications in comparison with traditional solutions. FIG. 2 shows the use of a rudder propeller in a ship lacking a bulb. In FIG. 3 there is a small low bulb and in FIG. 4 a large deep bulb.

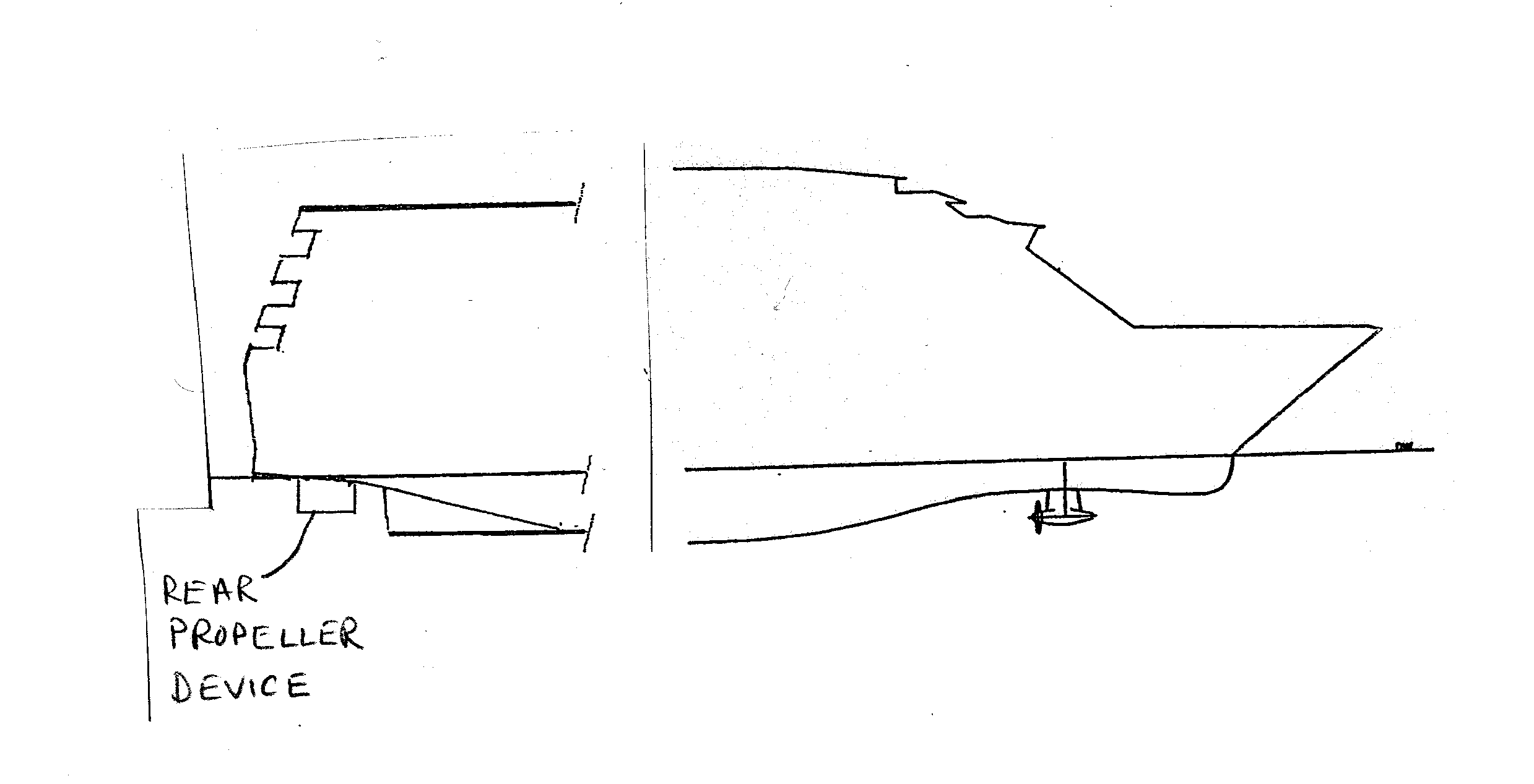

[0025]FIGS. 5-8 show how one or several rudder propeller devices can be arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com