Shoe brake for an elevator drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

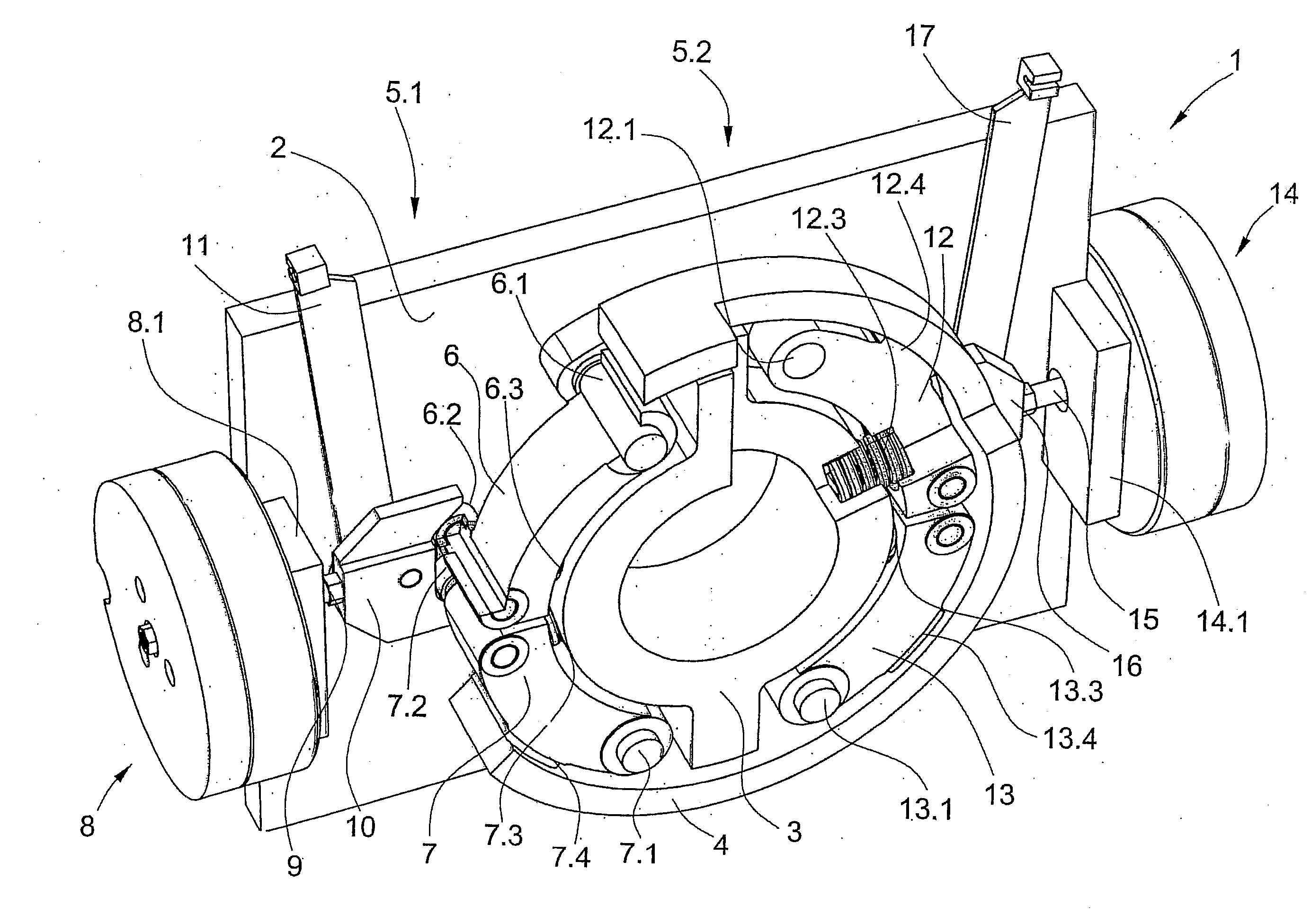

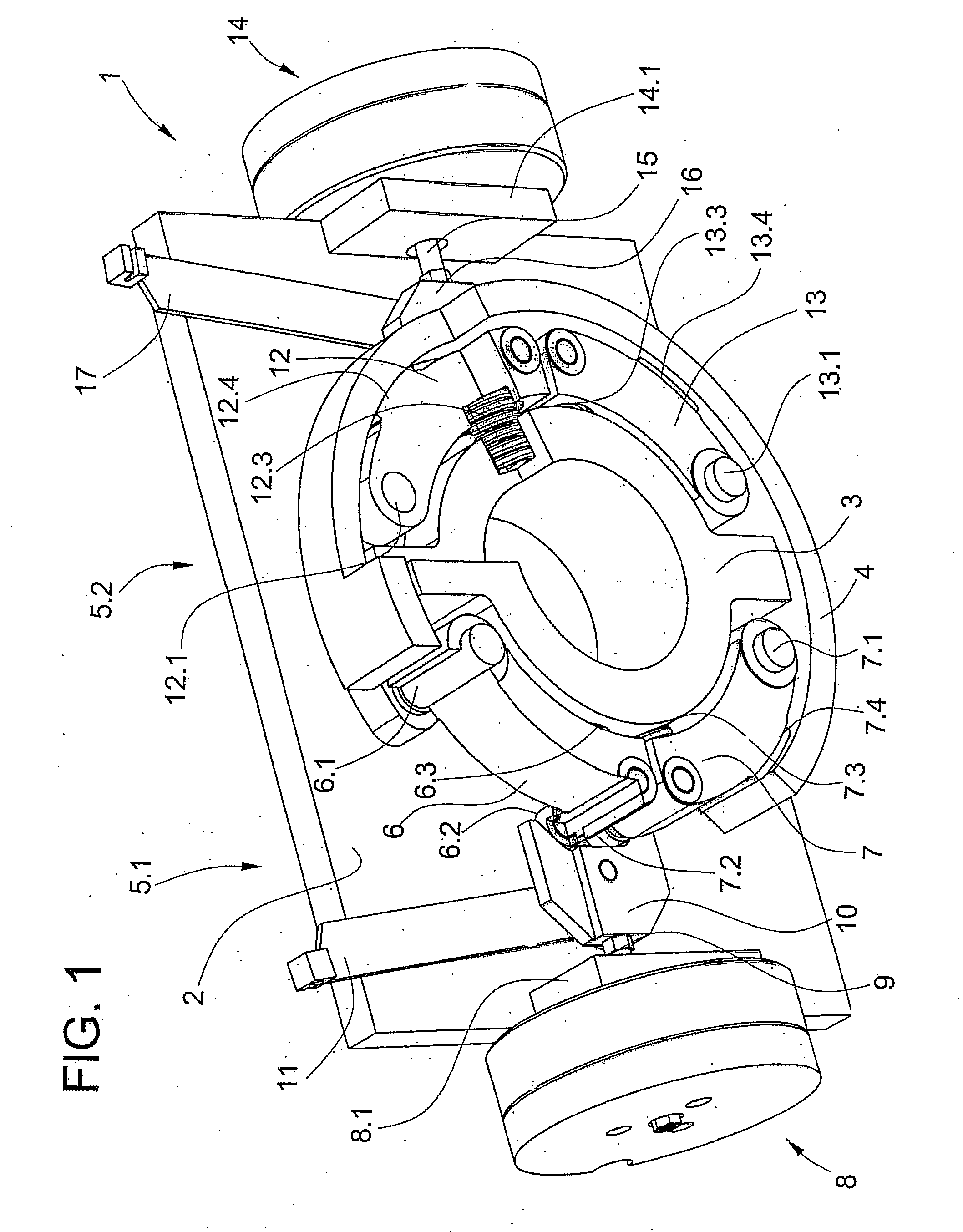

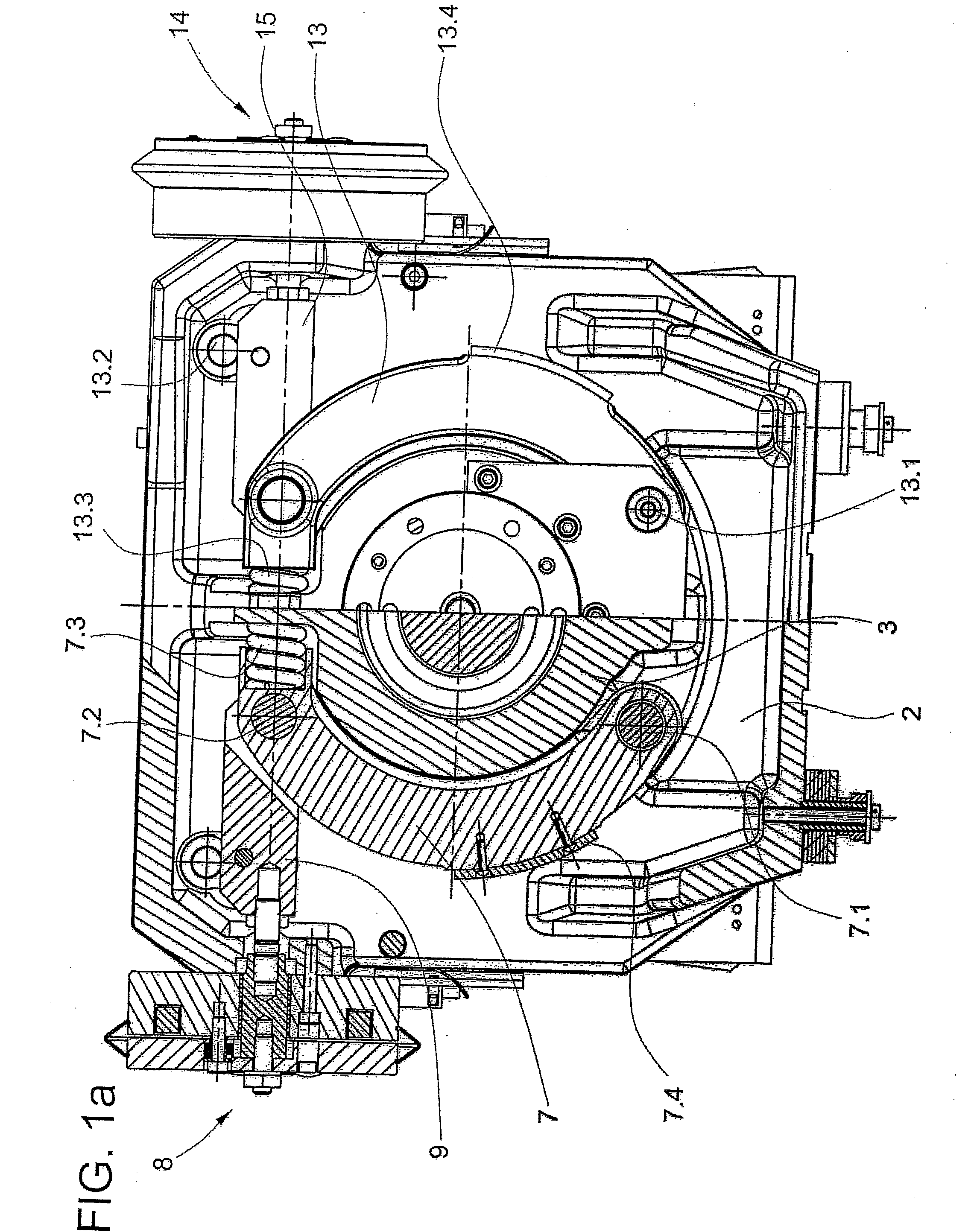

[0014]FIG. 1 is a perspective illustration of an internal shoe brake consisting of a housing plate 2, a housing ring 3, a brake drum 4 and two brake halves 5.1, 5.2 of identical construction. The brake drum 4 can be, for example, part of a drive pulley. The lefthand brake half 5.1 comprises an upper brake shoe 6 and a lower brake shoe 7. The upper brake shoe 6 is mounted at an upper brake bearing 6.1 and has at the opposed free end an actuating roller 6.2, and is pressed against the brake drum 4 by means of a compression spring 6.3 supported by the housing ring 3. The upper brake shoe 6 is illustrated in section, for which reason its brake lining is not apparent in FIG. 1. The section also runs through the roller axis at which the actuating roller 6.2 is arranged. The lower brake shoe 7 is constructed in mirror image to the upper brake shoe 6. Parts of the lower brake shoe are provided with the following reference numerals: shoe bearing 7.1, actuating roller 7.2, compression spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com